NJP-3800D Automatic Capsule Filling Machine

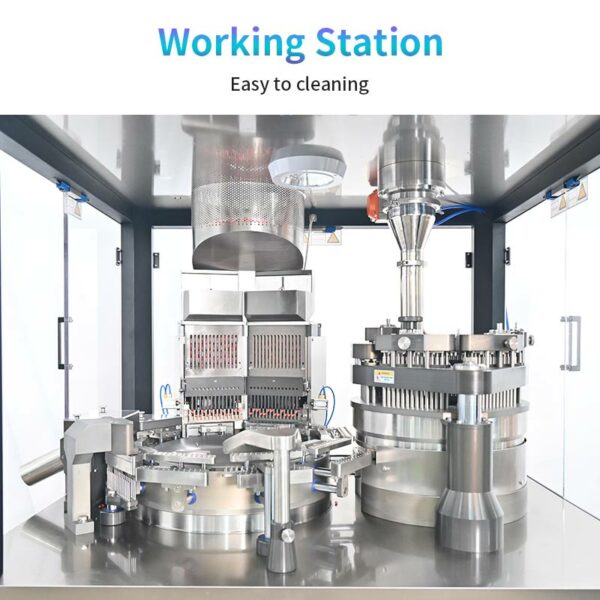

NJP-3800D automatic capsule filling machine is designed to fill empty capsules with powdered or granular substances, such as pharmaceutical ingredients, dietary supplements, or nutraceuticals, at a rapid rate.

Capsule Separation: The machine uses a separating mechanism (usually a set of cams or pneumatic systems) to split the capsule shells into two halves: the body (larger part) and the cap (smaller part).

Dosator Filling: A dosator, or filling cylinder, takes in a precise amount of powder and drops it into the capsule body.

Sealing: The machine uses a mechanical or pneumatic system to ensure the capsule halves are tightly sealed, preventing any powder leakage.

After the capsules are filled and inspected, they can be automatically packed into bottles, blister packs, or other forms of packaging depending on the required final output.

Specification:

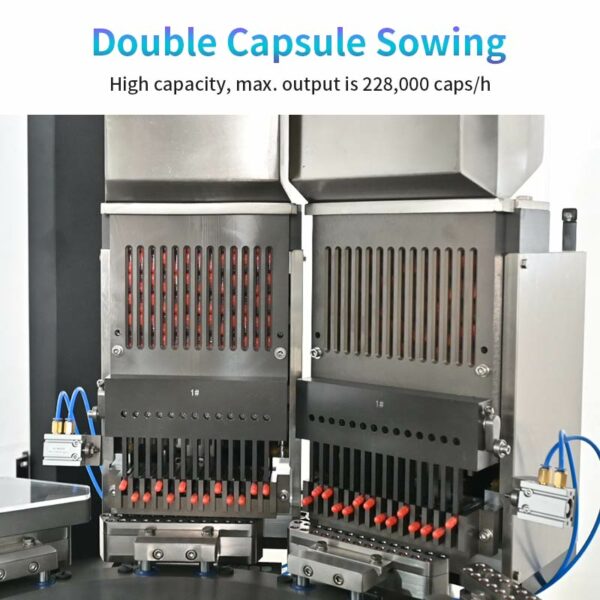

Up to 228,000 pcs/h

Appplicable for #000 ~ 5

Suitable for powder, granule, pellet, tablet