- Home

- Automatic Counting Machine

Automatic Counting Machine

It can count while pack all kinds of capsules, tablets and gummies into a bottle, which is suitable for scientific research institutions, hospitals, pharmaceutical factories, health products, factory production packaging. And it can also integrate with cartoning machine, labeling machine, etc.

Application:

Automatic Counting Machine is suitable for various different capabilities, including capsules, tablets, gummies.

Capsule(000~5#)

Tablet(3~40mm)

Gummy(3~40mm)

How It Works

Except for just simply counting and filling tablets and capsules into bottles, Rich Packing automatic counting machine is equipped with working sections and technologies to ensure a smooth and efficient production process.

Sorting Bottles

Organizing all the bottles for the preparation of filling.

Filling Ingredients

Filling all the materials into the counting machine.

Counting

Lining up in channels. Capsule, tablet or gummy can be counted and filled up to 9000 bottle/h.

Injecting Pills

Injecting pills into bottle with patent technology without shortage.

Waste Clearing

Clearing those defective bottles.

The Complete Range of Automatic Counting Machines

A wide variety of machine models with different capacity and budget for you to choose from.

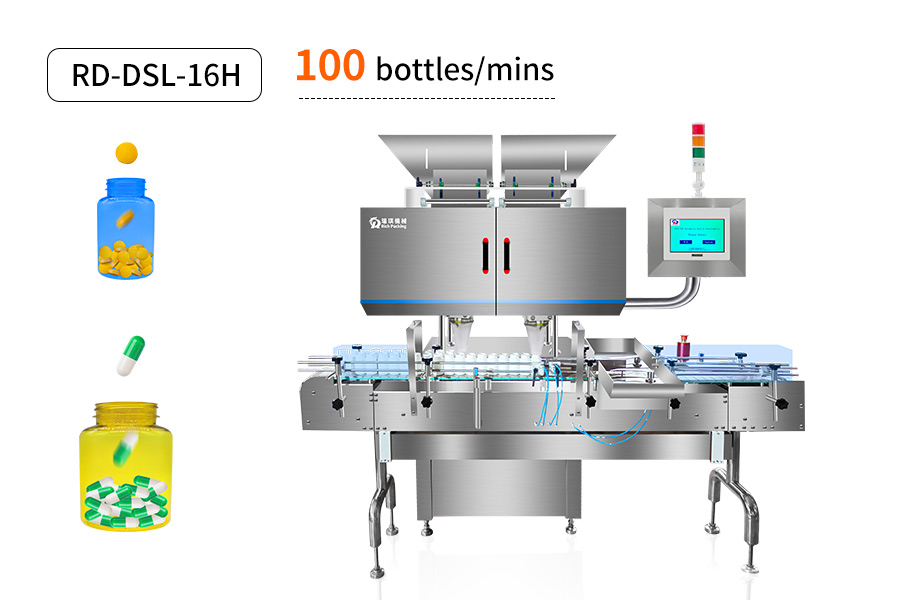

| Model | 8B | 12B | 16B | 16R | 16H | |

| Capacity | 10-35 bottles/minute | 15-45 bottles/minute | 20-85 bottles/minute | 100 bottles/minute | 127 bottles/minute | |

| Capable Material | 2-40mm Capsule/Tablet/Gummy... | |||||

| Accuracy Rate | >99.8% | >99.97% | >99.98% | |||

Need other Machine Model?

Wider Application:

Counting

Gummy, Candy…

Instead of only available for the tablet or capsules, our counting machine with special technologies can also capable of counting and filling nutrition supplements, such as vitamins, and even sticky gummy. It can extend more possibilities for your business.

- Separated lever design continuous sliding prevents sticking.

- Teflon coating on the channel allows a smooth delivery

- Wide PTFE hopper without gummy blockage

Fully Automatic Counting Line

Intended to operate completely from unscrambling the bottle to labeling a sticker on it, the automatic counting line is designed to help you get your capsules or tablets in a bottle that includes everything you need without hassle. It is afforadable and suitable for a wide range of tablet sizes.

Bottle Unscrambler

Counting Machine

Desiccant Inserter

Alu-foil Sealing Machine

Capping Machine

Labeling Machine

An Helping Hands for Packing Your Products

We are committed to manufacture machines with superior quality to meet GMP standards while with efficient and utility features.

Efficient without Stuck Pill

50% faster than similar models from other manufacturers and the pill won’t stuck with pneumatically filling design.

Pill Protection

The counting machine won’t damage your pills in the process, which reduces the material waste and inspection labor costs.

Stable around Dust

Our dust-resistant counting machines can still operate as usual and maintain an efficient performance in a dusty condition.

Automatic Rejection Stystem

With non-compliant capsules or tablets, the whole bottle will be automatically sorted out to the side.

We've Got Your Back with Comprehensive Service

Stand by you through the whole process, from choosing the suitable machine to taking good care of it for life.

Life-time Guarantee

To ensure premium performance for a long time, we offer free repairment within 3 years and free spare parts within 1 year. After that, we promise a free technical consultation for a lifetime.

Fast Delivery in 7 Days

95% of our standard machines are in stock. In such case, the shipping can arrive within 7 days. As for in-depth customized products, it is only 20 days for delivery.

24/7 Online Service

Our knowledgeable customer experts and engineers will target your needs and solve all your problems within 24 hours.

Frequently Asked Questions

Yes, our capsule counting machine can count tablets without modifying anything.

Yes, we can integrate the capsule counting machine to the capsule filling machine for you. And if you also need to integrated cartoning machine, we can also provide you a solution. Please contact us with your specific details.

CE: Conformite Europeenne GMP: Good Manufacturing Practices ISO: International Standards Organization FDA: Food and Drug Administration

Here are some main specifics that you need to consider, such as product size, production capacity, machine size, and warranty. Due to the cost of the machine being a huge budget, a complete and long aftersale service can also help a lot for a long run business.

Yes, please feel free to send the specifics to us and we will provide a suitable solution for your demands. Our machines can cover most of the sizes, and we can also provide customization services.

- Check and clean the electrical part is neat and dust-free to prevent line failure.

- Clean to avoid the shock plate from corrosion after the production is completed.