- Home

- Capsule Filling Machine

- Semi-automatic Capsule Filling Machine

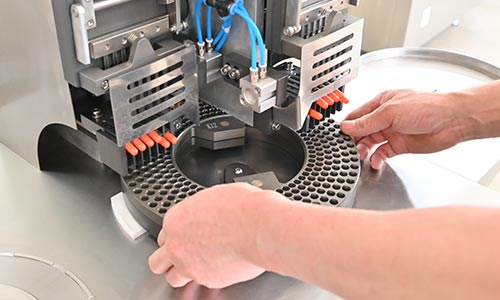

Semi-automatic Capsule Filling Machine

The production of semi-automatic capsule filling machine needs assistance from an operator by moving the filling plates between the different sections in the process. It‘s more cost-friendly and user-friendly.

Capable Capsule sizes:

|  |  |  |  |  |  |  | |

| Capsule Size | #000 | #00 | #0 | #1 | #2 | #3 | #4 | #5 |

| Locked Length | 26.14mm | 23.30mm | 21.7mm | 19.4mm | 18.0mm | 15.9mm | 14.3mm | 11.1mm |

| Capsule Volume | 1.37 ml | 0.91 ml | 0.68 ml | 0.5 ml | 0.37 ml | 0.3 ml | 0.21ml | 0.13ml |

(The filling amount may vary because of the powder difference)

How Semi-automatic Capsule Filling Machine works?

The Complete Range of Semi-automatic Capsule Filling Machines

| Model | CGN-208 | CGNT-209 |

| Output | 28,000pcs/h | 40,000pcs/h |

| Applicable Capsule | 000#、00#、0#、1#、2#、3#、4#、5# | |

| Power supply | 2.12kw | 2.2kw |

| Power | 380/220V 50Hz(customizable) | |

| Net weight | 400kg | 405kg |

| Packing size | 1640*720*1700mm | 1640*720*1700mm |

A Wise Investment for Pharma

Easy to Use

Cost-Friendly

Accurate

Safe to Operate

No Pollution

We've Got Your Back with Comprehensive Service

Life-time Guarantee

Fast Delivery in 7 Days

24/7 Online Service

Frequently Asked Questions

- Lubricate cam regularly to keep it in good condition.

- Disassemble and clean the filling station to clear the excess material to prevent blockage and rust, after the production is finished.

- Add lubricating oil to the vacuum pump regularly and clean up the dust.

- Fill enough water over half of the barrel body in water tank regularly.

Semi-automatic Capsule Filling Machine Working Principle

A semi-automatic capsule filling machine separates empty capsules, fills them with the desired material, and closes them.

It involves following steps:

- Capsule separation

- Filling station setup

- Filling the hopperial

- Capsules alignment and orientation

- Dosage adjustment

- Filling the capsules

- Capsule Closing

- Ejecting the filled capsules

Automatic vs. Semi-automatic Capsule Filling Machine

Automatic Capsule Filling Machine

Pros:

Automatic machines offer high-speed production capabilities, filling capsules quickly and efficiently, which is beneficial for large-scale manufacturing.

They require minimal manual intervention, reducing the need for extensive human labor and increasing productivity.

Automatic machines are designed for precise dosing, ensuring consistent and accurate filling of capsules.

They often come with additional features such as capsule sorting, automatic capsule orientation, and online inspection systems, enhancing overall operational efficiency.

Cons:

Automatic machines tend to have a higher upfront cost compared to semi-automatic machines, making them a significant investment.

Operating and maintaining automatic machines may require specialized training and technical expertise due to their complex nature.

These machines may have limitations when it comes to accommodating small-batch production or frequent product changes.

Automatic machines are generally larger and require more space in the manufacturing facility.

Semi-automatic Capsule Filling Machine

Pros:

Semi-automatic machines are generally more cost-effective, making them a viable option for smaller manufacturers or startups with limited budgets.

They offer more flexibility in terms of production versatility, allowing easier adaptation for small-scale or diverse product lines.

Semi-automatic machines are relatively simpler to operate and require less technical expertise, enabling easier training and maintenance.

These machines are typically smaller, occupying less space in the production area.

Cons:

Semi-automatic machines require more manual handling, involving operators in the capsule filling process, which can be time-consuming and potentially introduce errors.

The filling speed is limited by manual handling, resulting in slower production rates compared to automatic machines.

There may be slight variations in filling accuracy or capsule quality due to the manual nature of the process.

Some semi-automatic machines may be less durable or prone to more frequent breakdowns compared to their automatic counterparts.