- Home

- Blister Packing Machine

Blister Packing Machine

Blister packing machine is commonly used in the pharmaceutical, food, and healthcare industries. It securely packages tablets, capsules, ampoules, and other small products, protecting them from moisture, light, and contamination, while also providing tamper-evident packaging for enhanced safety and extended shelf life.

Application:

Blister Packaging Machine is suitable for various different capabilities, including capsules, tablets, and liquids.

How It Work

With the functions of fully automatic forming, feeding, heat sealing, batch number coding, punching and counting. It can automatically seal tablets, capsules, candy, and sauces into an alu-pvc or alu-alu blisters.

The Complete Range of Blister Packing Machines

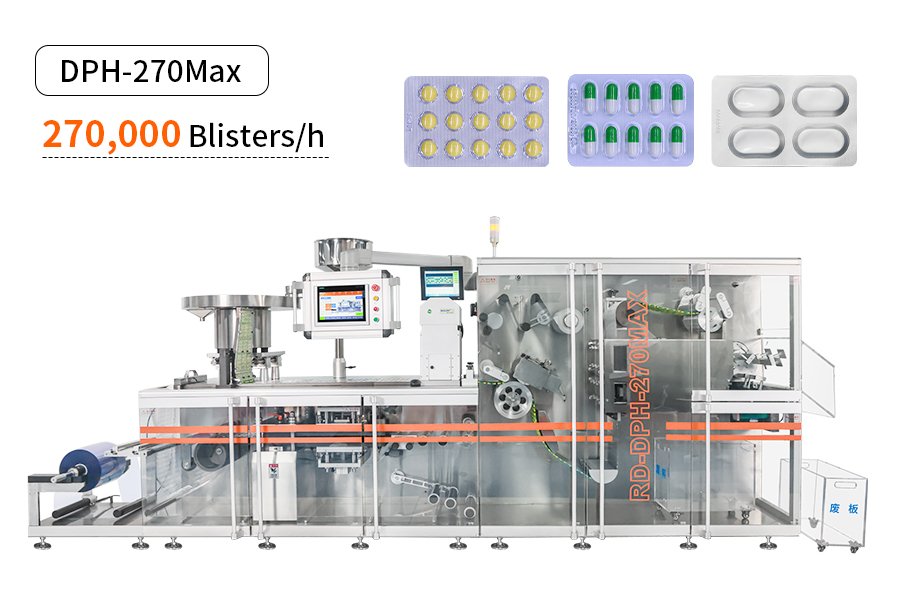

| Model | DPP-90R | DPP-100L | DPP-180Pro | DPP-270L | DPP-270Max | DPH-270Max |

| Output | 2,300 Blisters/h | 2,300 Blisters/h | 4,800 Blisters/h | 9,600 Blisters/h | 11,200 Blisters/h | 27,000 Blisters/h |

| Max. Blister Size | 80*110*15mm | 80*110*15mm | 170*120*15mm | 255*125*15mm | 255×125*15mm | 205×260*12mm |

| Max. Depth | 26mm | 26mm | 26mm | 26mm | 26mm | 26mm |

For Tablet / Capsule and Other Solids :

DPP-270Max High Speed Blister Packing Machine

DPP-270Max high speed blister packing machine find extensive application in diverse industries, including packaging, pharmaceutical, and chemical.

For Perfume / Jam / Honey and Other Liquid :

An Helping Hands for Packing Your Products

An Helping Hands for Packing Your Products

We've Got Your Back with Comprehensive Service

Life-time Guarantee

Fast Delivery in 7 Days

24/7 Online Service

Frequently Asked Questions

- Check whether the screws of each station are tightened and the mold pressure is overloaded before each production.

- Lubricate the cam box and the connection with mold regularly.

- When the equipment is not in use, disassemble and oil seal the forming, heat sealing and cutter dies.

What Is Blister Packaging Machine?

A blister packaging machine is a mechanical device used in the pharmaceutical, medical, and other industries to package products in blister packs.

Blister packs consist of individual compartments or cavities that hold the product, typically tablets, capsules, or other solid dosage forms, within a transparent plastic or aluminum material.

Blister packaging machines are widely used in pharmaceutical and healthcare industries due to their ability to provide a secure and tamper-evident packaging solution.

Advantages of Blister Packaging

Product Protection

Accurate Dosing

Tamper-Evidence

Product Identification

Improved Branding