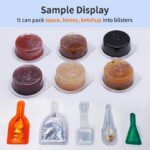

Honey Blister Packing Machine

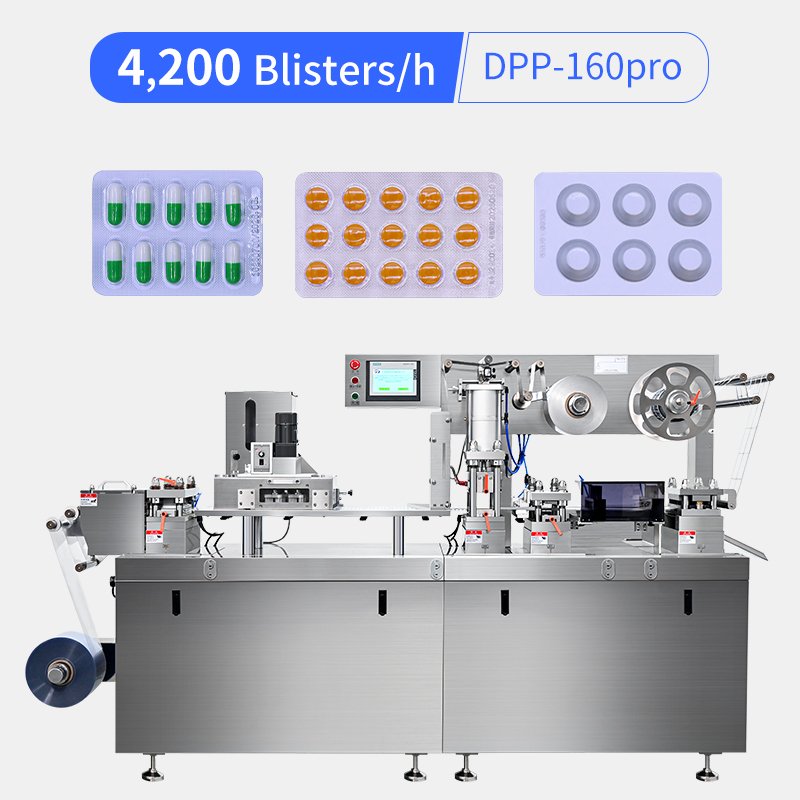

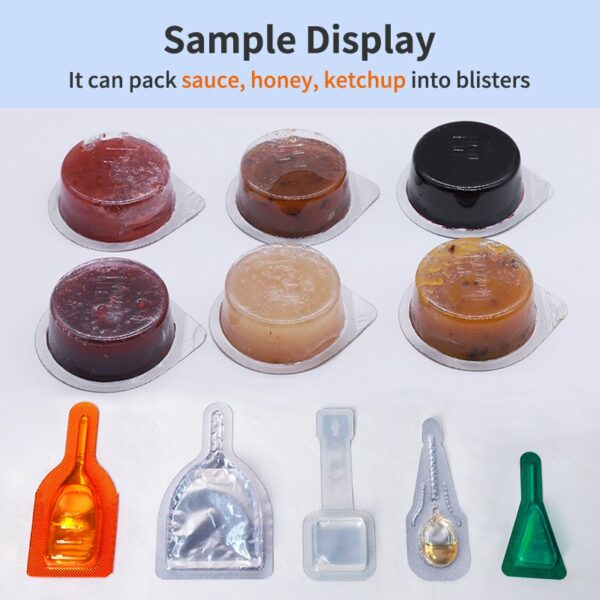

Honey blister packing machine wIth the functions of fully automatic forming, feeding, sealing, punching, counting, and batch number coding, It can automatically seal perfume, jam, honey into an aluminum-plastic composite panel or aluminum plate.

Forming Blisters: The machine heats and forms the blister cavities in the film. These cavities will hold the honey.

Filling the Honey: Once the blisters are formed, the peristaltic pump injects the liquid into the blister. Different pumps are selected according to different raw materials.

Sealing: After filling, a top film, often aluminum foil, is unrolled and placed over the filled blisters. The machine then applies heat and pressure to seal the top film to the bottom film, enclosing the honey in airtight blisters.

Not only liquids can be put into alu-pvc blister, but also medicine, such as tablet capsule blister machine.

Specification:

Up to 9,600 blisters/h

Applicable for jam, honey, perfume…

15 Days Fast Delivery