- Home

- Capsule Filling Machine

Capsule Filling Machine

Classification of Capsule filling Machine

| Machine Model | NJP-400C | NJP-800C | NJP-1500D | NJP-2600C | NJP-3800D | NJP-5500C |

| Maximum Output | 24000 pcs/h | 48000 pcs/h | 90000 pcs/h | 150000 pcs/h | 228000 pcs/h | 330000 pcs/h |

| Capsule Sizes Compatibility | 000,00,0,1,2,3,4,5# | |||||

| Power | 3KW | 5KW | 5.5KW | 8KW | 10.5KW | 11KW |

| Weight | 600Kg | 900Kg | 1200Kg | 1500Kg | 2200Kg | 3000Kg |

| Dimension | 1000×710×1900mm | 1100×910×2100mm | 1490×1260×2150mm | 1650×1490×2150mm | 1980×1850×2200mm | 2400x2050x2300mm |

| Model | CGN-208 | CGNT-209 |

| Output | 15000-30000pcs/h | 40000pcs/h |

| Applicable Capsule | 000#、00#、0#、1#、2#、3#、4#、5# | |

| Power supply | 2.12kw | 2.2kw |

| Power | 380/220V 50Hz(customizable) | |

| Net weight | 400kg | 405kg |

| Packing size | 1640*720*1700mm | 1640*720*1700mm |

| Model | CGNL-300 | NJPL-100C | NJPL-300C | NJPL-600C |

| Output | 15000-28000pcs/h | 100 pcs/min | 300 pcs/min | 600 pcs/min |

| Capsule Sizes Compatibility | 00#、0#、1#、2#、3# | |||

| Total Power | 2.12kw | 3.5KW | 5KW | 6KW |

| Power | 380/220V 50Hz(customizable) | |||

| Weight | 400KG | 500KG | 750KG | 900KG |

| Dimension (L*W*H) | 1300*800*1750mm | 700*800*1700mm | 860*960*1800mm | 960*1000*1900mm |

Not sure which machine is best for you? Our team can provide a proposal based on your needs and budget!

Automatic Capsule Filling Machine

Benefits

- Less labor costs

- Higher output than semi-automatic with one operator

- Integrated automation to complete capsule

- The whole process without pollution

Application:

- size:#000 to #5

- Ingredients: pellet, powder, granule

Semi-automatic Capsule Filling Machine

- Easy to Use

- Lower Machine Costs

- Higher Output with More Operators

- size:#000 to #5

- Ingredients: pellet, powder, granule

Semi Automatic Capsule Filler Machine

Semi automatic capsule filler machine can fill powder, granule, pellet and liquid into hard capsule, suitable for capsule size #000-5.

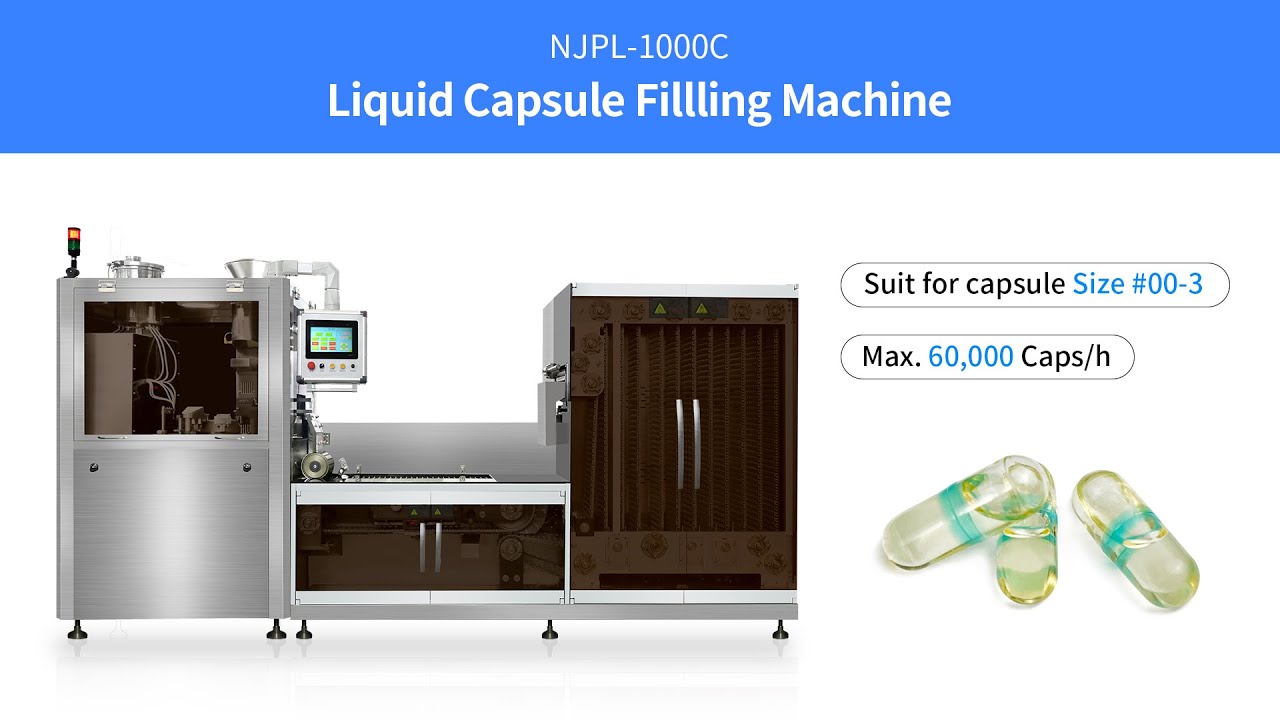

Liquid Capsule filling Machine

Benefits

- Latest technologies without leakage

- The whole process without pollution

- Various liquid application

Application:

- size: #000 to #3

- Ingredients: liquid, oil, liquid/mini capsule, liquid/mini tablet, liquid/pellet

A Wise Investment for Pharma

Wide Application

High Accuracy

Cost Effective

No Messy Workshop

We've Got Your Back with Comprehensive Service

Life-time Guarantee

Fast Delivery in 7 Days

24/7 Online Service

Frequently Asked Questions

- Lubricate cam regularly to keep it in good condition.

- Disassemble and clean the filling station to clear the excess material to prevent blockage and rust, after the production is finished.

- Add lubricating oil to the vacuum pump regularly and clean up the dust.

- Fill enough water over half of the barrel body in water tank regularly.

Capsule Filling Machine Working Principle

Step #1: Capsule Separation

The machine separates the empty capsules into individual halves, typically using mechanical or vacuum-based mechanisms.

Step #2: Filling Material

The desired fill material, such as powders or granules, is loaded into a hopper.

Step #3: Capsule Closing

The machine brings the capsule halves together, aligns them, and securely closes them using either mechanical pressure, vacuum suction, or a combination of both.

Step #4: Ejection

Once the capsules are closed, they are released from the machine, either into a container or for further packaging.

What Is Capsule Filling Machine?

A capsule filling machine is a device used in the pharmaceutical, nutraceutical, and herbal industries to automate the process of filling empty capsules with various substances such as powders, granules, pellets, or liquids.

It consists of different components, including a capsule hopper, a mechanism for separating and orienting the capsules, a filling system, a closing mechanism, and an ejection system.

The machine facilitates efficient and precise filling of capsules, ensuring accurate dosage and uniformity. It helps increase production speed, reduce labor costs, and maintain quality control in capsule manufacturing processes.

Main Types of Capsules

Hard-Shelled Capsules

- Hard-shelled capsules, also known as two-piece capsules, are composed of separate cap and body sections that fit together to enclose the fill material. The cap and body are typically made of gelatin or vegetarian materials.

- Hard capsules offer excellent product protection, stability, and tamper-evident features. They are commonly used for dry powders, granules, or small solid particles.

Soft-Shelled Capsules

- Soft-shelled capsules are composed of a single, flexible gelatin or vegetarian shell. They are often referred to as softgels or softgel capsules. Softgels are typically filled with liquid or semi-solid materials, such as oils, suspensions, or pastes.

- The soft shell provides advantages such as enhanced bioavailability for lipid-based formulations, improved stability for light-sensitive compounds, and ease of swallowing.