NJP-1500D Automatic Capsule Filling Machine

NJP-1500D automatic capsule filling machine is a specialized piece of equipment used in the pharmaceutical, nutraceutical, and supplement industries to fill empty capsules with powdered or granular materials, such as medication, vitamins, or dietary supplements. These machines automate the filling process, ensuring accuracy, efficiency, and consistency in capsule production.

Ruidapacking have different model machine meet your needs, such as:

Semi-Automatic Capsule Filling Machines: These machines combine manual and automated processes. The operator loads the capsules and supervises the filling, but the machine automates much of the process. They offer a balance between efficiency and cost-effectiveness, ideal for medium-scale production.

Liquid capsule filling machine: Used to fill capsules with liquid formulations. These machines are essential in the pharmaceutical, nutraceutical, and supplement industries for producing liquid-filled capsules, which are often preferred for their faster absorption rates and ease of swallowing.

Specification:

Up to 90,000 cap/h

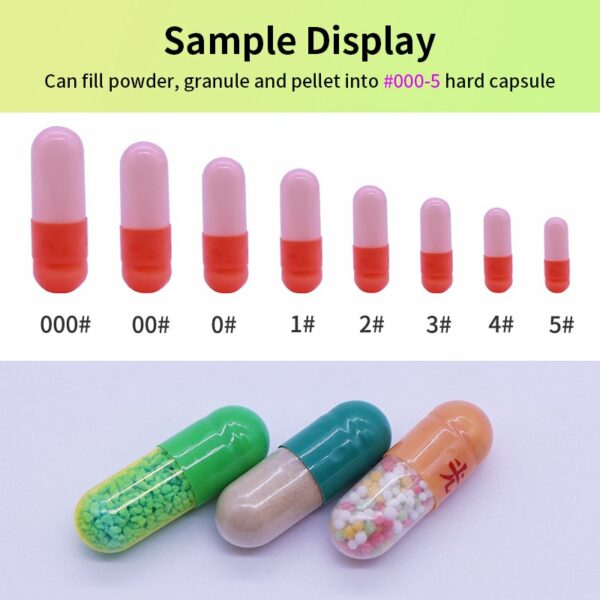

Appplicable for #000 ~ 5 capsule

15 Days Fast Delivery

Suitable for powder, granule, pellet