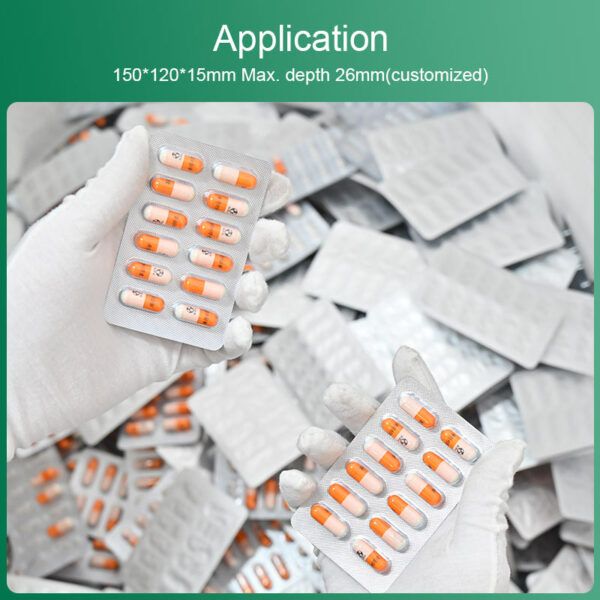

Blistering Machine In Pharmaceutical Industry

Aluminum blister packing machine With the functions of fully automatic forming, feeding, sealing, punching, counting, and batch number coding, It can automatically seal tablets, capsules and e-cigarette into an alu-pvc or alu-alu blister.

Specification:

Up to 4,200 blisters/h

Applicable for tablets, capsules and e-cigarette

Modular design, change mold 15mins, easy to operation

Suitable for PVC、PS、PET material