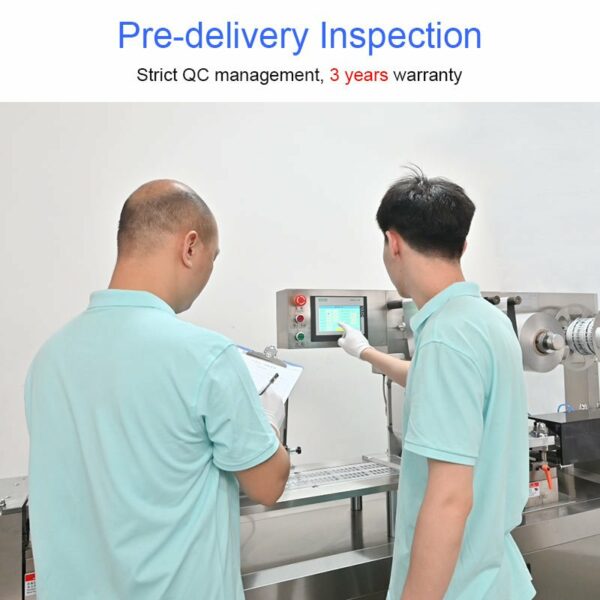

DPP-160pro Blister Packing Machine

DPP-160pro blister packing machine with the functions of fully automatic forming, feeding, sealing, punching, counting, and batch number coding, It can automatically seal tablets, capsules and e-cigarette into an alu-pvc or alu-alu blister.

Types of Blister Packing Machines:

Thermoforming Machines: Use heat and pressure to form plastic blisters.

Cold Forming Machines: Use pressure to shape the aluminum film into blisters without heating.

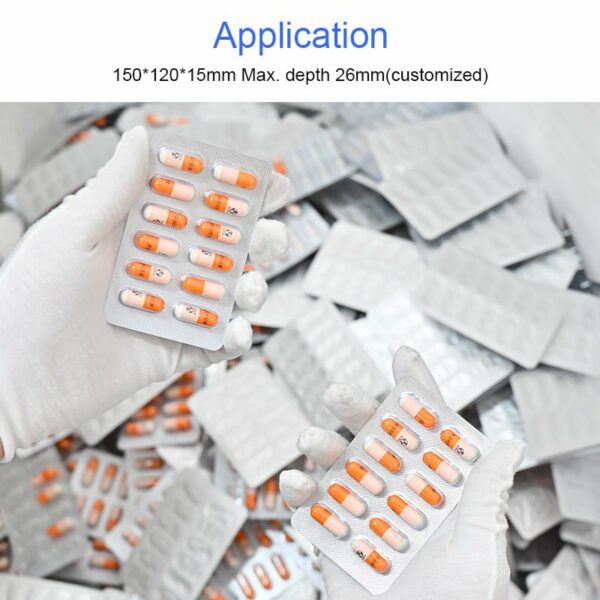

Applications:

Pharmaceutical industry for packaging tablets, capsules, and other medications.

Consumer goods for items like batteries, toys, and electronic components.

Food industry for packaging small items like candies and chewing gums.

Specification:

Up to 4,200 blisters/h

Applicable for tablets, capsules and e-cigarette

15 Days Fast Delivery

Suitable for PVC、PS、PET material