- 집

- 자동계수기

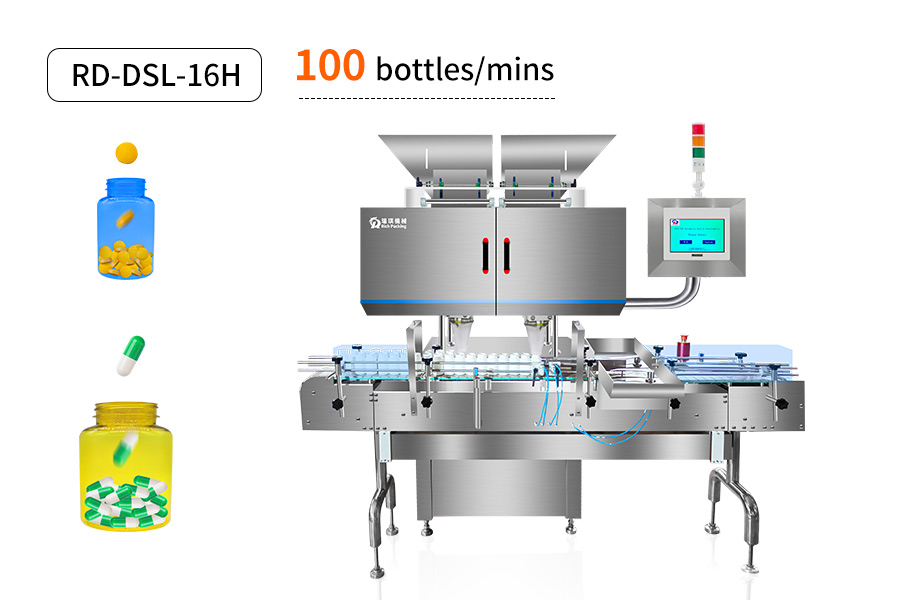

자동계수기

It can count while pack all kinds of capsules, tablets and gummies into a bottle, which is suitable for scientific research institutions, 병원, pharmaceutical factories, 건강 제품, factory production packaging. And it can also integrate with cartoning machine, 라벨링 머신, 등.

애플리케이션:

Automatic Counting Machine is suitable for various different capabilities, 캡슐을 포함하여, 정제, gummies.

Capsule(000~5#)

Tablet(3~40mm)

Gummy(3~40mm)

작동 방식

Except for just simply counting and filling tablets and capsules into bottles, Rich Packing automatic counting machine is equipped with working sections and technologies to ensure a smooth and efficient production process.

Sorting Bottles

Organizing all the bottles for the preparation of filling.

Filling Ingredients

Filling all the materials into the counting machine.

Counting

Lining up in channels. 캡슐, tablet or gummy can be counted and filled up to 9000 bottle/h.

Injecting Pills

Injecting pills into bottle with patent technology without shortage.

Waste Clearing

Clearing those defective bottles.

The Complete Range of Automatic Counting Machines

다양한 용량과 예산을 갖춘 다양한 기계 모델 중에서 선택할 수 있습니다..

| 모델 | 8B | 12B | 16B | 16R | 16시간 | |

| 용량 | 10-35 bottles/minute | 15-45 bottles/minute | 20-85 bottles/minute | 100 bottles/minute | 127 bottles/minute | |

| Capable Material | 2-40mm Capsule/Tablet/Gummy... | |||||

| Accuracy Rate | >99.8% | >99.97% | >99.98% | |||

태블릿 및 캡슐 계산 충전 기계

Tablet and capsule counting filling machine involves several precise steps designed to ensure accurate counting and efficient filling into containers.

다른 기계 모델이 필요합니다.?

Wider Application:

Counting

거미, Candy…

Instead of only available for the tablet or capsules, our counting machine with special technologies can also capable of counting and filling nutrition supplements, such as vitamins, and even sticky gummy. It can extend more possibilities for your business.

- Separated lever design continuous sliding prevents sticking.

- Teflon coating on the channel allows a smooth delivery

- Wide PTFE hopper without gummy blockage

Fully Automatic Counting Line

Intended to operate completely from unscrambling the bottle to labeling a sticker on it, the automatic counting line is designed to help you get your capsules or tablets in a bottle that includes everything you need without hassle. It is afforadable and suitable for a wide range of tablet sizes.

병 스크램블러

계산 기계

건조제 투입기

Alu-foil 씰링 기계

캡핑 기계

라벨 기계

제품 포장을 위한 도움의 손길

우리는 효율적이고 실용적인 기능을 갖춘 동시에 GMP 표준을 충족하는 우수한 품질의 기계를 제조하기 위해 최선을 다하고 있습니다..

Efficient without Stuck Pill

50% faster than similar models from other manufacturers and the pill won’t stuck with pneumatically filling design.

Pill Protection

The counting machine won’t damage your pills in the process, which reduces the material waste and inspection labor costs.

Stable around Dust

Our dust-resistant counting machines can still operate as usual and maintain an efficient performance in a dusty condition.

Automatic Rejection Stystem

With non-compliant capsules or tablets, the whole bottle will be automatically sorted out to the side.

포괄적인 서비스로 여러분을 도와드립니다.

모든 과정을 함께 해주세요, 적합한 기계를 선택하는 것부터 평생 잘 관리하는 것까지.

평생 보증

오랫동안 프리미엄 성능을 보장하기 위해, 우리는 이내에 무료 수리를 제공합니다 3 년 이내에 무료 예비 부품 1 년도. 이후, 평생 무료 기술상담을 약속드립니다..

빠른 배송 7 날

95% 우리의 표준 기계 중 재고가 있습니다. 그러한 경우, 배송은 이내에 도착할 수 있습니다 7 날. 심층적인 맞춤형 상품으로는, 이건 그냥 20 배송일.

24/7 온라인 서비스

우리의 지식이 풍부한 고객 전문가와 엔지니어는 귀하의 요구 사항을 목표로 삼고 모든 문제를 해결할 것입니다. 24 시간.

자주 묻는 질문

예, our capsule counting machine can count tablets without modifying anything.

예, we can integrate the capsule counting machine to the capsule filling machine for you. And if you also need to integrated cartoning machine, we can also provide you a solution. Please contact us with your specific details.

CE: 유럽 GMP 규정 준수: 우수제조관리기준 ISO: 국제표준기구 FDA: 식품의약품안전청

고려해야 할 몇 가지 주요 세부 사항은 다음과 같습니다., such as product size, 생산 능력, 기계 크기, 및 보증. 기계 비용이 막대한 예산이기 때문에, 완전하고 장기적인 애프터 서비스는 장기적인 비즈니스에 많은 도움이 될 수 있습니다..

예, 구체적인 내용을 보내주시면 귀하의 요구에 적합한 솔루션을 제공해 드리겠습니다.. 우리 기계는 대부분의 크기를 다룰 수 있습니다, 그리고 우리는 또한 맞춤 서비스를 제공할 수 있습니다.

- Check and clean the electrical part is neat and dust-free to prevent line failure.

- Clean to avoid the shock plate from corrosion after the production is completed.