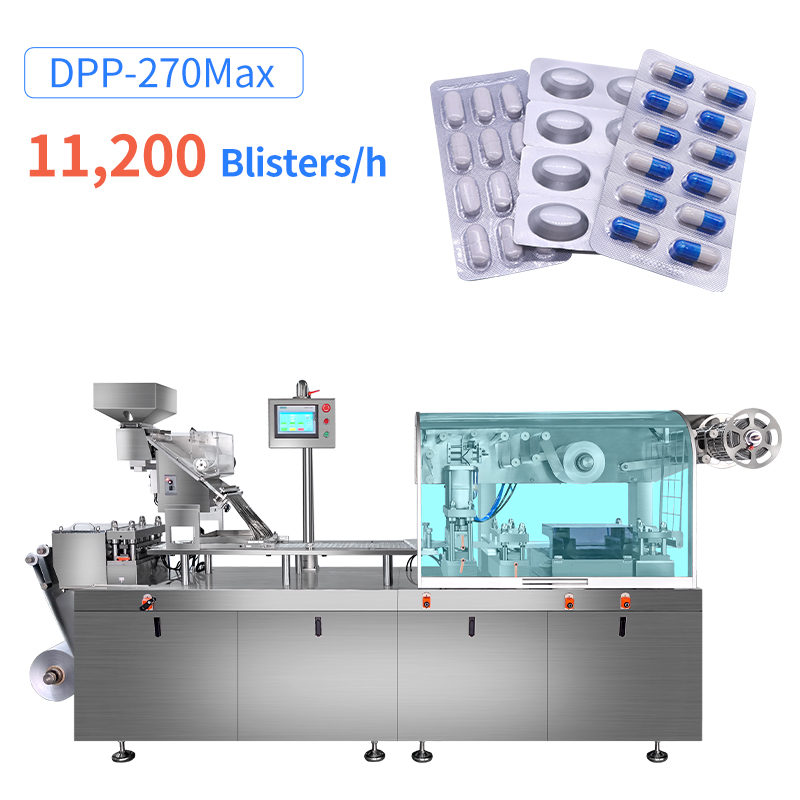

DPP-260R Blister Packing Machine

WIth the functions of fully automatic forming, feeding, sealing, punching, counting, and batch number coding, It can automatically seal tablets, capsules and e-cigarette into an aluminum-plastic composite panel or aluminum plate. An ideal way to pack your product efficiently and cost-effectively.

Specification:

Up to 10,800 plates/h

Applicable for tablets, capsules and e-cigarette

15 Days Fast Delivery

Suitable for PVC、PS、PET material