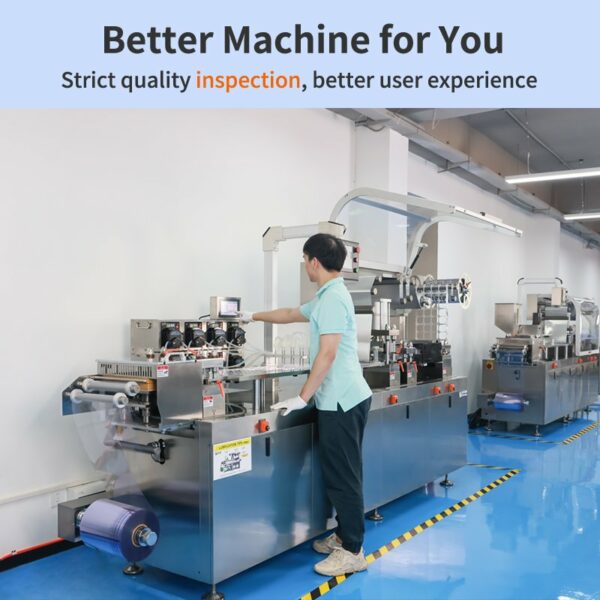

DPP-270L Sauce Blister Packing Machine

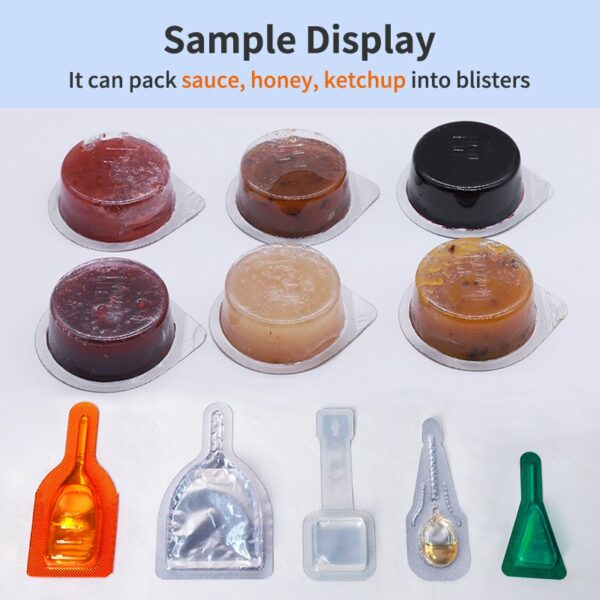

DPP-270L sauce blister packing machine is designed to pack liquid products (such as syrups, oils, or creams) into individual blister packs.

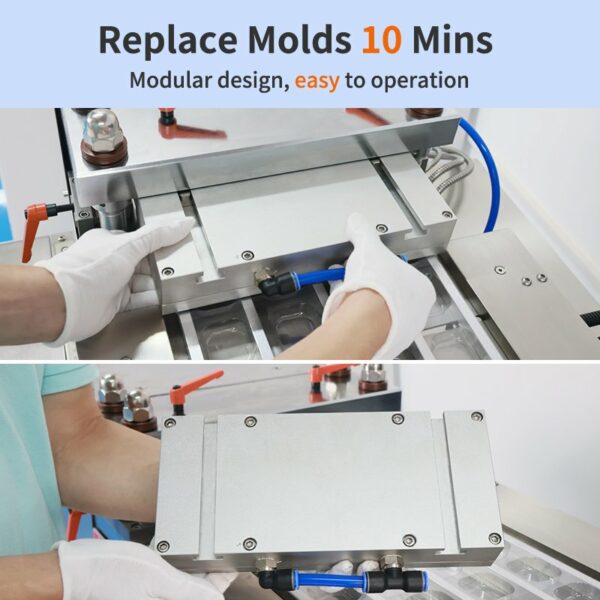

Heating and Molding: The film is heated to a specific temperature to make it soft and pliable. It then passes into a forming station where it is molded into individual pockets (blisters) using a set of molds. A vacuum or air pressure is used to help shape the film into cavities that will hold the liquid product.

Dosing Mechanism:This can include a pump, nozzle, or volumetric system to ensure accurate filling of the correct amount of liquid into each blister.

Sealing Process: The filled blister packs are passed through a sealing station where heat and pressure are applied to bond the lidding film to the base film. This creates a sealed pocket, protecting the liquid product from contamination, leakage, or spoilage.

Cutting: After sealing, the machine cuts the continuous strip of blisters into individual packs.

Specification:

Up to 9600 plates/h

Applicable for perfume, jam, honey…

Suitable for PVC、PS、PET material