Capsule Filling Semi-automatic

The production of capsule semi auto filling machine encapsulation needs assistance from an operator by moving the filling plates between the different sections in the process. It full meets CE, ISO, cGMP, USA and EU standard.

Specification:

Up to 40,000 caps/h

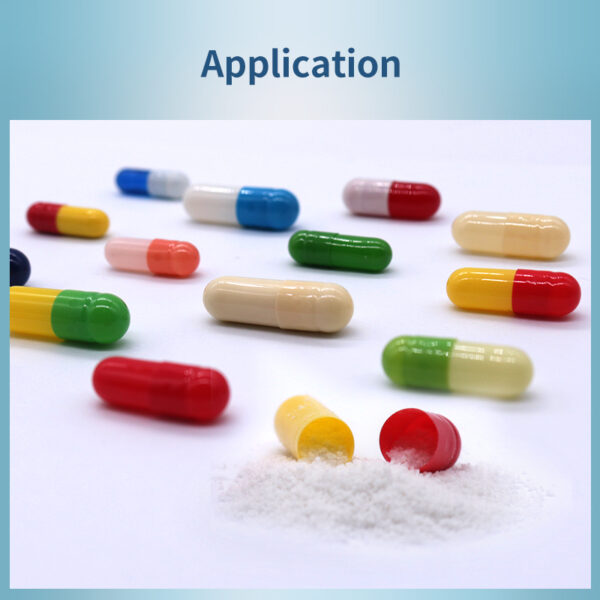

Appplicable for 000# ~ 5# capsule

15 Days Fast Delivery

Suitable for powder, granule, pellet, tablet