CGN-208 Semi Automatic Capsule Filling Machine

CGN-208 semi automatic capsule filling machine needs assistance from an operator by moving the capsule tray between the different station in the process.

The semi-automatic capsule filling machine with diverse applications in the pharmaceutical and healthcare industries. It is commonly used in small to medium-scale production for filling capsules with various substances.

Main application areas is in the pharmaceutical. It enables precise filling of powdered or granular drugs, ensuring accurate dosage and consistent quality. This is crucial for drugs that require specific concentrations and formulations for therapeutic effectiveness.

In the field of dietary supplements, the semi-automatic capsule filling machine is also widely employed. It helps in encapsulating vitamins, minerals, and herbal extracts, making it convenient for consumers to take their supplements in an easy-to-swallow form.

Specification:

Up to 28,000 pcs/h

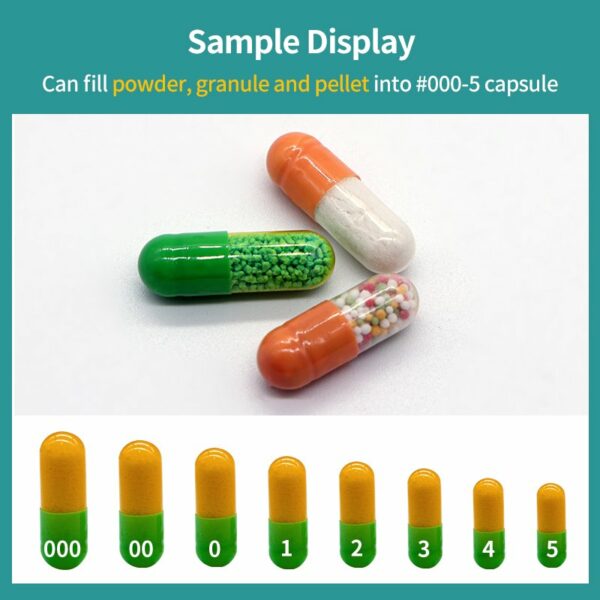

Suitable for powder, granule, pellet, tablet