Capsule filling machine, also known as capsule filler or encapsulation machine, used to fill empty capsules with various substances such as powder, granules, pellet or liquids. The machines are essential in the pharmaceutical, nutraceutical, and supplement industries for producing capsules efficiently and consistently.

What is capsule?

Capsule is a dosage form used to deliver medications, dietary supplements, and other active ingredients orally. It consists of a shell that encloses the active ingredients, protecting them from the environment and making them easier to ingest.

Hard Gelatin Capsules: Composed of two rigid shells (a body and a cap) that fit together. Made primarily from gelatin derived from animal collagen. Typically filled with powdered or granular substances.

Soft Gelatin Capsules (Softgels): Made from a more flexible gelatin or similar material, forming a single-piece shell. Can filling liquids, oils, or semi-solids.

Vegetarian Capsules: Made from plant-derived materials like hydroxypropyl methylcellulose (HPMC) or pullulan. Suitable for the same types of contents as gelatin capsules.

Advantages of Capsules

Ease of Swallowing: Smooth texture and shape make them easy to swallow.

Taste Masking: The shell can mask unpleasant tastes and odors of the contents.

Precision: Allows for accurate dosing of active ingredients.

Protection: The shell protects sensitive ingredients from light, air, and moisture.

Versatility: Suitable for a wide range of substances, including powders, granules, liquids, and oils.

Type of capsule filling machine

Capsule filling machines categorized based on their level of automation. The machines currently on the market can be divided into:

Manual capsule filling machine

Automatic capsule filling machine

Fully automatic capsule filling machine is a sophisticated piece of equipment designed to streamline the process of filling empty capsules with various types of substances, such as powders, granules, liquids, or semi-solids. These machines are essential in the pharmaceutical, nutraceutical, and supplement industries due to their efficiency, precision, and ability to handle high production volumes.

full automatic capsule filling machine working principle

full automatic capsule filling machine involves several key steps. Automatic Capsule Feeding, capsule Separation, capsule fillling(powder, granule and pellet), rejection, capsule locking and outputing.

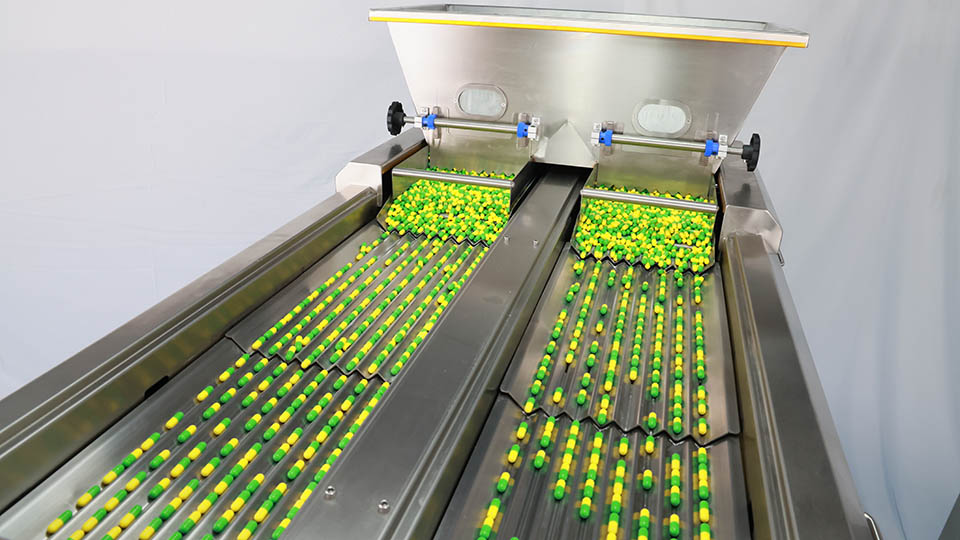

Vacuum feeding machine: First, the capsules automatically enter the hopper through the vacuum feeding machine. The hopper is equipped with a material detection system. When the capsules are less than the set value, the loading machine automatically works to replenish the capsules; when the capsules reach 3/4 of the hopper, the loading machine stops working.

Capsule sowing: The capsule orienter ensures that the capsules enter the separation station in the correct direction, with the capsule cap on top and the capsule body on the bottom. After the capsule enters the separation station, the vacuum suction device will suck the capsule cap and separate it from the capsule body. After separation, the capsule body and capsule cap are positioned on different workbenches, the capsule body is held on a low bench while the capsule cap is lifted onto a high bench, ready for filling.

Capsule filling: The powder is delivered to the filling station through the vacuum feeding machine. When the filling station has insufficient powder, the feeding machine start working. When the powder reaches 3/4, the feeding machine stops working, and the filling rod fills the powder into the capsule body, this process is repeated multiple times to achieve the desired fill weight. The filling volume is adjusted through the metering plate and the filling rod scale, which is simple and convenient; the filling station is modular designed, and the filling rod can be replaced in 15 minutes, making it easy to clean and maintain.

Capsule Reject: There are two situations for capsule rejection: the first is that the hollow capsule has been locked when it is purchased. The capsule filling mechanism cannot separate the capsule, and the cap body is not separated, so the filling mechanism cannot fill the powder and reject the capsule; the second is It is good to buy hollow capsules, but the capsules not separated in the capsule filling mechanism, so the capsules are removed.

Capsule locking: The capsule locking station to ensure that the filled capsule body and capsule cap are firmly connected together, form a complete capsule. Capsule locking is performed by accurately positioning and aligning the capsule cap onto the capsule body and applying appropriate pressure or force.

Capsule Ejection:The filled and sealed capsules are ejected from the machine. They are collected in a designated container or moved to the next stage of processing, such as capsule polishing or capsule packaging.

Full automatic capsule filling machine advantage

Automatic capsule filling machines offer numerous advantages, particularly in industrial settings where efficiency, accuracy, and productivity are paramount. Here are some of the key benefits:

High Efficiency and Productivity: The machines can fill 12,000-468,000 cap/h, significantly increasing production capacity compared to manual or semi-automatic machines. Capable of running continuously, allowing for large-scale production runs.

Precision and Consistency: Advanced filling mechanisms ensure precise fill weights, which is critical for maintaining dosage accuracy and product efficacy. Consistent filling reduces the risk of variation between individual capsules, ensuring each capsule meets quality standards.

Labor Cost Savings: Automation reduces the need for manual intervention, lowering labor costs and minimizing human error. Operators can manage multiple machines simultaneously, further optimizing workforce utilization.

Hygiene and Safety: Automatic capsule filling machines are designed to meet stringent hygiene standards, minimizing the risk of contamination. This is crucial in pharmaceutical and nutraceutical production. Many machines feature enclosed filling systems, reducing exposure to dust and airborne particles, protecting both the product and workers, Meets cGMP standards.

Flexibility: Capable of handling various capsule sizes and types (e.g., hard gelatin, vegetarian), and different types of fill materials (powders, granules, pellets, liquids, and semi-solids). It can be easily adjusted for different production requirements, making them adaptable to various product formulations.

Quality Control: Capsule filler machine come with built-in quality control features such as weight checks and reject mechanisms for non-conforming capsules. Can log production data, providing valuable insights for quality assurance and regulatory compliance.

Cost-Effectiveness: Precision filling mechanisms minimize product waste, enhancing cost efficiency. High-speed and efficient operation reduce overall production costs, providing a good return on investment over time.

Automatic capsule filling machines are a critical investment for pharmaceutical, nutraceutical, and supplement manufacturing companies. They offer substantial benefits in terms of efficiency, accuracy, cost savings, and compliance with hygiene and safety standards. By automating the capsule filling process, manufacturers can achieve higher production volumes, consistent product quality, and overall improved operational efficiency.

Full automatic capsule filling machine application

Capsule filling machines are used in a variety of industries. Here are some of the main applications:

Pharmaceutical Industry: prescription medications, over-the-counter (OTC) medications, clinical trials.

Nutraceutical Industry: dietary supplements, probiotics.

Food Industry: nutritional supplements, functional foods.

Herbal and Traditional Medicine: herbal supplements, traditional Medicines.

Capsule filling machines play a vital role in various industries by providing an efficient, precise, and scalable method for producing capsules.