Tablet press is a kind of equipment widely used in pharmaceutical, food, chemical and other fields. It is a mechanical equipment used to press powder or granular materials into solid tablets. It works by filling raw materials into a mold and then applying high pressure to bind them tightly, ultimately forming tablets of the desired shape and size. Tablet compression machine usually consist of a filling system, a pressing system, a mold and a driving system.

In a filling system, the raw material powder or granules are delivered to the filling tank or mold of the tablet making machine. After filling, the machine applies pressure to compact the raw materials and form solid tablets. Mold selection determines the final tablet shape and size, so mold design and manufacturing is critical. The drive system usually uses an electric motor or hydraulic system to provide the required power.

Types of tablet press machine

There are many types of tablet presses, each designed for specific uses and production needs. Here are some common types:

Single punch tablet press

The single-punch pill press is a common tablet making machine. Its working principle is briefly as follows: First, powder or granular raw materials are filled into the filling tank or mold of the pill press through the feeding system. Subsequently, the machine is started and high pressure is applied to compact the raw material tightly within the mold. During the compaction process, gaps between raw material particles are eliminated, forming solid tablets. Once tableting is complete, the tablets are ejected from the mold through an ejection system. Single-punch pill presses usually have simple structure and operation and are suitable for small-scale production and laboratory research. Its working process is relatively intuitive and tablets are prepared through a single compression, so it is widely used in the pharmaceutical industry and laboratories. Although the production efficiency of a single-punch pill press is relatively low, its flexibility and ease of operation make it ideal for low-volume production and new product development.

Rotary tablet press

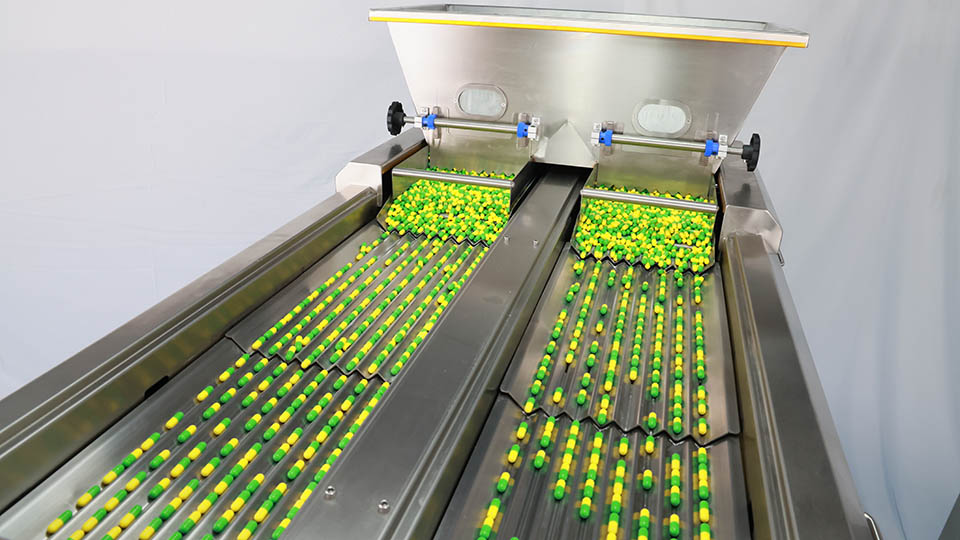

The rotary tablet presses is a commonly used piece of equipment in the pharmaceutical industry. Its working principle is based on a continuous rotary design. It mainly includes key steps such as feeding, compaction, and discharge.

First, the raw material powder or granules are filled into the mold through the feeding system. Subsequently, the mold enters the tableting area as the turntable rotates. At the same time, high pressure is applied from the upper and lower molds to compact the raw materials into tablets. During the tableting process, two stages, pre-compression and main compression, may be used to ensure tablet consistency and quality. As the turntable rotates, the tablets are smoothly discharged and collected through the discharge system or entered into subsequent processing. Rotary tablet presses are usually equipped with multiple tableting stations, allowing multiple tablets to be prepared simultaneously, improving production efficiency. In addition, it can be equipped with automated control systems that monitor parameters of the tableting process, such as pressure, speed and filling volume, to ensure the stability and consistency of production. Rotary tablet presses are widely used to manufacture various types of tablets, only change molds, such as regular tablets, controlled-release tablets, chewable pieces, etc., and can be used in the production of solid preparations in other fields. Its working principle is simple and efficient, and its production efficiency is high, so it is favored by the pharmaceutical industry.

Double-layer tablet press

Double-layer tablet press machine is a device used to manufacture double-layer tablets and its working principle is based on a rotary tablet press. During the working process, the raw material powder is first filled into the bottom of the mold, and then the upper mold moves above the filling area. Subsequently, the compression of the first layer begins, and a certain amount of pressure is applied to compact the raw materials to form the bottom tablet. Then, the upper mold moves over the bottom tablet, is filled with raw material powder, and the second layer of compression begins. Through the continuous filling, compaction and discharge process, the double-layer tablet press can simultaneously manufacture tablets of two different drugs or different formulas, achieving efficient production of double-layer tablets. This design makes bilayer tablets widely used in the pharmaceutical industry, especially for the production of drugs that require two drugs to be combined together or that require different release characteristics.

Tablet press application

Tablet machine is a widely used equipment in pharmaceutical, chemical, food and other industries. It is mainly used in the production process of solid preparations. In the pharmaceutical industry, tablet presses are used to manufacture various types of tablets, including regular tablets, controlled-release tablets, chewable tablets, etc., by filling drug powder or granular materials into molds and applying high pressure to form a solid tablet. In the chemical industry, tablet presses can be used to produce solid chemicals, detergents, soaps and other solid products. In the food industry, tablet presses are used to manufacture food tablets of various shapes and sizes, such as vitamin tablets, chewing gum, etc. In addition to this, tablet presses can also be used in the metal powder metallurgy and ceramic industries to manufacture tablet products. In general, tablet presses, as key equipment in the production of solid dosage forms, play an important role in multiple industries and provide efficient and precise manufacturing technology support for product production.

Ruida Packing has been deeply involved in pharmaceuticals and packaging machinery for more than 30 years. It first produced single-flush products. After more than ten years of accumulation, with the changes in the market, single-flush products can no longer meet the market demand. The company began to focus on research and development, spending huge human and financial resources to build its own rotary tablet press. At first, it did not sell single punches, and the sales department focused on high-speed tablet presses.

As one of China’s top 10 pharmaceutical and packaging machinery suppliers, Ruida Packing not only provides a variety of high-quality machinery and equipment, but also provides complete solutions and services. If you have needs, we will give you the best service.