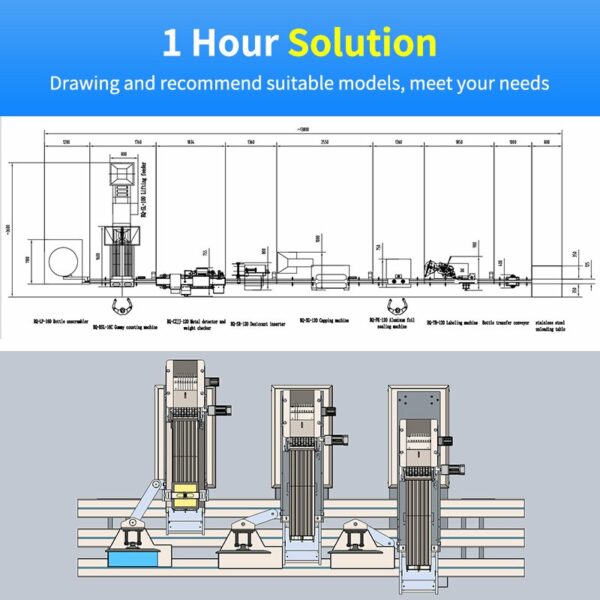

Count Bottling Line for Tablets Capsules

The Count Bottling Line for Tablets Capsules production operates through a series of coordinated steps designed to ensure the efficient and accurate packaging of pharmaceutical products.

Counting Machine: As each bottle reaches the filling station, a nozzle dispenses the counted tablets or capsules into the bottle.

Capper Machine: The capper machine places and tightens caps onto each bottle. This step can include various types of capping methods such as screw-on, press-on, or snap-on caps.

Sealer: For tamper-evident packaging, an induction sealer may be used to apply a heat-sealed foil over the bottle opening.

Labeling Machine: Bottles are then transported to the labeling station where labels with product information, batch numbers, and expiry dates are applied.

Specification:

Up to 70 bottles/min

15 days delivery

Suitable for 3-40mm tablets, capsules, gummies…