Blister packaging as a common pharmaceutical packaging method in the pharmaceutical industry, since its inception has been the preferred choice for mass production tablet packaging in the pharmaceutical packaging industry due to its wide range of applicability, safety and brand recognition. Blister packaging was originally designed to package tablets and capsules, replacing high-cost glass and plastic bottle packaging lines with blister packaging machines. Blister blister packaging has proven to be suitable for the transportation and storage of pharmaceuticals due to its good air tightness and good protection. In today’s era when pharmaceutical companies are demanding more and more packaging for their drugs, blister blister packaging is still the preferred packaging method in the pharmaceutical industry.

Pharmaceutical manufacturers often choose to purchase the right blister packaging machine based on production volume, product characteristics and packaging quantity. There are three common types of blister packaging machines on the market today: roller, plate and roller plate. Plate and roller type blister packaging machine is the most common. Various types of blister packaging machines have their advantages and disadvantages. We will describe their features in detail to help you choose the most suitable machine for your products.

Types and Characteristics of Common Blister Packaging Machines

Rotary Blister Packaging Machine

The rotary blister packaging machine operates based on the principle of vacuum thermoforming. It features continuous packaging, which enables high production efficiency. It is suitable for large-scale production due to its ability to handle a relatively high production volume in a short time. However, it has limitations when it comes to deep blister forming. The structure and working mode of the machine may not be able to achieve a satisfactory deep blister shape, which could be a drawback for some specific packaging requirements of solid tablets.

Plate Blister Packaging Machine

In a plate blister packaging machine, during the heat sealing process, the upper and lower molds make planar contact. This type of machine is more suitable for small and medium batch production of pharmaceuticals. It shows advantages in packaging items with special shapes. For example, for some irregularly shaped solid tablets, the plate blister packaging machine can better adapt to the shape and ensure accurate packaging. Additionally, it has a relatively large blister stretching ratio, which allows for more flexibility in packaging design and can better accommodate different sizes and shapes of tablets.

Rotary Plate Blister Packaging Machine

The rotary plate blister packaging machine combines the advantages of both the rotary and plate types. It adopts a flat plate forming mold, which provides better controllability and accuracy in the forming process, especially for products that require a more precise blister shape. At the same time, it utilizes a rotary continuous sealing method, inheriting the high efficiency characteristics of the rotary type. This makes it a more versatile option, capable of meeting a wider range of production needs and packaging requirements for solid tablets in pharmaceutical enterprises.

Selection of Blister Packaging Materials

Commonly used medicinal blister packaging materials include PVC (Polyvinyl Chloride), PVDC (Polyvinylidene Chloride), and composite materials. PVC is a widely used material due to its relatively low cost and good formability. It can provide a certain degree of protection for the tablets. However, its gas barrier properties may not be as excellent as some other materials. PVDC has better moisture and gas barrier properties, which can effectively extend the shelf life of the packaged drugs. Composite materials, on the other hand, are often designed to combine the advantages of different materials. For example, a combination of plastic and aluminum foil can provide both good mechanical strength and excellent barrier properties, making them suitable for high-quality and long-term storage of solid tablets. The selection of packaging materials depends on the specific characteristics and storage requirements of the solid tablets, as well as the cost and market positioning of the pharmaceutical products.

Key Points in Selecting a Blister Packaging Machine

Production Demand

The production scale of the pharmaceutical enterprise is a crucial factor. If the production volume is large, a machine with high production efficiency like the rotary blister packaging machine or the rotary plate blister packaging machine may be more suitable. For smaller production batches, the plate blister packaging machine or a more flexible machine that can be easily adjusted for different batch sizes could be a better choice. Additionally, the expected production growth in the future should also be considered to ensure that the selected machine can meet the long-term production needs of the enterprise.

Product Characteristics

The shape, size, and special requirements of the solid tablets need to be taken into account. For tablets with irregular shapes or special coatings that require more gentle handling, a machine with better controllability and precision, such as the plate blister packaging machine or the rotary plate blister packaging machine with accurate forming and sealing processes, may be preferred. If the tablets are sensitive to moisture or oxygen, the selection of packaging materials and the sealing performance of the machine become even more critical to ensure the quality of the drugs.

Packaging Materials

The compatibility of the machine with different packaging materials is essential. Some machines may be better suited for specific types of materials. For example, if the enterprise plans to use PVDC or composite materials with higher requirements for heat sealing and forming, it is necessary to ensure that the selected blister packaging machine can achieve the desired packaging effect with these materials. The machine should also be able to handle the characteristics of the packaging materials, such as the softening temperature and stretching properties, to ensure the integrity and quality of the packaging.

Precision Requirements

In the pharmaceutical industry, high precision is required to ensure accurate dosing and packaging. The blister packaging machine should be able to accurately control the size and shape of the blisters to match the size of the solid tablets. Any deviation in the packaging may lead to incorrect dosing or affect the appearance and quality of the product. Therefore, machines with advanced control systems and precise mechanical structures are preferred to meet the strict precision requirements of pharmaceutical packaging.

Equipment Quality and Stability

The quality and stability of the blister packaging machine directly affect the production efficiency and product quality. A machine with high-quality components and a reliable manufacturing process is more likely to operate stably for a long time, reducing downtime for maintenance and repair. It is important to choose a reputable manufacturer and conduct thorough inspections and tests before purchasing the machine to ensure its quality and performance. Additionally, after-sales service and technical support from the manufacturer are also crucial factors to consider, as they can provide timely assistance in case of any problems during operation.

Future Development Trends

In the future, the blister packaging technology and equipment for solid dosage forms in the pharmaceutical industry will show several development trends.

Automation

Automation will continue to advance. With the increasing demand for production efficiency and quality control, blister packaging machines will be equipped with more intelligent automation systems to achieve automatic feeding, packaging, and quality inspection, reducing human error and labor costs.

High-speed

high-speed operation will be a key development direction. Pharmaceutical enterprises are constantly striving to increase production capacity, and high-speed blister packaging machines will be able to meet this demand, while ensuring the quality and accuracy of packaging.

Diversification

Diversification of packaging forms and functions will emerge. In addition to the basic packaging functions, blister packaging may incorporate more features such as anti-counterfeiting, traceability, and patient-friendly design to meet the diverse needs of the market and regulatory requirements.

Intelligent

The integration of intelligent technologies will become more prominent. Blister packaging machines may be connected to the Internet of Things (IoT) and use data analytics and artificial intelligence to optimize production processes, predict equipment failures, and improve overall production efficiency and quality management. Pharmaceutical enterprises need to keep abreast of these trends and choose blister packaging machines that are compatible with future development to enhance their competitiveness in the market.

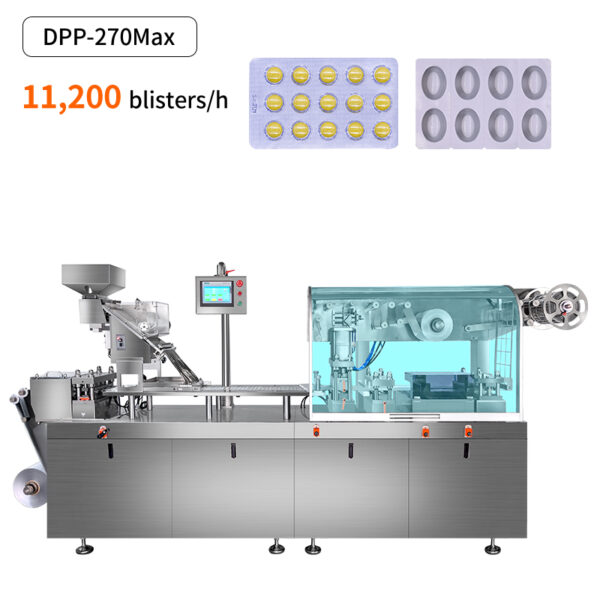

Product Recommendation: DPP-270Max Blister Packaging Machine

When selecting a blister packaging machine for the pharmaceutical industry, the DPP-270Max Blister Packaging Machine stands out as an excellent choice. This machine is designed to enhance packaging efficiency and ensure product safety, making it suitable for use in various production environments within pharmaceutical companies.

Key Features of the DPP-270Max:

High Efficiency: The DPP-270Max can achieve rapid packaging speeds, significantly improving production efficiency. Its design allows for quick mold changes, facilitating the handling of different specifications of medications to meet market demands flexibly.

Precise Packaging: With an advanced control system, the DPP-270Max ensures accuracy in every package, minimizing waste. This is especially crucial in the pharmaceutical industry, effectively preventing overfilling or underfilling of medications.

User-Friendly Design: The machine features an intuitive operating interface, enabling operators to easily set up and monitor the packaging process. Additionally, the DPP-270Max is easy to clean and maintain, saving time and labor costs for businesses.

Versatility: This equipment is not only suitable for capsules and tablets but also capable of packaging various shapes and sizes of medications, broadening its application range. Whether for small pharmaceutical companies or large manufacturers, the DPP-270Max can meet diverse production needs.

Safety: The DPP-270Max incorporates high-standard safety measures to protect both operators and products during operation, adhering to international pharmaceutical industry standards.

In summary, the DPP-270Max Blister Packaging Machine, with its outstanding performance and reliability, is an ideal choice for the pharmaceutical industry. It can help businesses stand out in a competitive market. If you are looking for a machine that enhances production efficiency and ensures product quality, the DPP-270Max is undoubtedly a worthy investment in premium equipment.