When you take medicine or health products, you usually encounter softgel capsules other than tablets and pills. Most softgel capsules are oval and subtransparent, with attractive looks and smooth surfaces. Do you wonder why there is always liquid inside the softgel capsules? What is the liquid gel capsule made of? How is it made?

In this article, the author is going to introduce liquid softgel capsules and the basic ingredients of softgel capsules. Furthermore, how a liquid gel capsule filling machine produces softgel capsules during its manufacturing process will be included to give you an overall understanding.

What is a Liquid Soft-Gel Capsule?

Source: pinterest

A liquid softgel capsule is comprised of a solid capsule as the outer shell and a liquid as the inner fill. Softgel capsule is a one-piece capsule filled with liquid and a kind of medicine for oral dosage. The shell of the softgel capsule contains several ingredients including gelatin, water, an opacifier, and a plasticizer. A soft gelatin capsule is thicker than a hard capsule as it needs extra ingredients like glycerin to get a soft texture. It is suitable for liquid fillings so it is in widespread use for various pharmaceutical substances and nutritional supplements.

Softgel capsules have lots of qualities due to their main ingredient, gelatin. It can dissolve at normal body temperature, then supplements or medications inside the capsule can be absorbed by human bodies. Besides, it prevents oxygen, moisture, dust, and light from polluting the actives in the drug. Different colors and sizes of capsules also help customers differentiate various medications. Many customers like softgel capsules more than tablets and pills because they are tasteless and easy to be swallowed.

Nutrients and drugs can have higher bioavailability in soft gels so liquid softgel capsules are increasingly popular in pharmaceutical applications. Bioavailability is essential for pharmaceutical companies during the manufacturing process. A good liquid gel capsule filling machine can guarantee that the actives can be released in the right place and ensure consistent and accurate dosage. The liquid capsule filling machine can work automatically to fill and seal the liquid in the capsule and provides an ideal solution for drug firms.

Softgel Capsules Ingredients

Source: Pinterest

The ingredients of softgel capsules usually include gelatin or its substitutes, plasticizers, opacifiers, preservatives, colorants, and flavorings. They have corresponding roles in softgel capsules.

The main ingredient of softgel capsules is gelatin. It is a pure protein, free from fat and cholesterol. It is extracted from collagen, which is derived from the bones and skins of animals such as pigs, cattle, and sheep. Gelatin is often applied as a food additive in many food products like desserts, jelly, yogurt, and marshmallows. Gelatin can melt under a warm temperature and solidify into a gel in a cool environment. This quality makes it a perfect substance for a capsule shell. That’s why a soft gel capsule can dissolve and release fillers within minutes after it enters into human intestines. Meanwhile, it is safe and harmless for human bodies.

The other two substitutes for gelatin are pullulan and hypromellose, which are not derived from animals. Pullulan is a polysaccharide that is soluble in water, comprised of maltotriose units, and is made from starch by the fungus Aureobasidium pullulans. Hypromellose is produced from raw cellulose. Both of them have received wide recognition around the globe and have been widely used for many years. Tapioca starch is also a viable alternative to gelatin derived from vegetable cellulose. Vegan materials often have higher bioavailability than gelatin.

Other ingredients are added in softgel capsules for different reasons. Plasticizers are added to soft gelatin capsules to keep their elasticity and stability. Most capsules are transparent, so opacifiers are added to prevent the fill matrix from sunlight. At the same time, preservatives can obstruct the deterioration. Furthermore, colorants and flavorings can be incorporated to make the finished product savory.

Gel capsule filling machines with high performance can integrate all of the above materials in an appropriate method to produce liquid softgel capsules with high quality.

Manufacturing Process

Source: colorhub

The manufacturing process of liquid softgel capsules may vary for diverse capsules, but it commonly consists of four sections. The following paragraphs will give a brief introduction for each section and interpret the machinery involved in the production.

Making the Capsule

The first step of the manufacturing process is to make a capsule. To begin with, a machine melts and mixes all the ingredients including gelatin, water, plasticizer, and additives in the right proportion. Different contents of coloring agents and additives can customize various kinds of softgel capsules. The blend of four main components produces a softgel shell with high durability. The shell has to keep warm to maintain the consistency of a liquid. When the capsule shell is finished, manufacturers can use equipment such as sieves, mills, processing tanks, or vacuum homogenizers to fill ingredients inside the softgel. Softgel capsule is a one-piece capsule and is hermetically sealed.

Encapsulation

The process of encapsulation happens in a room with a constant temperature and humidity of around 20% because an optimal environment is significant for a high-quality final product. The mixture of gelatin is poured into two cold drums. When the drums roll constantly, the mixture solidifies and rolls off as a solid sheet that is split in half. Then each half will be cut into a proper shape and size. A heated wedge of the liquid gel capsule filling machine will enwrap the two halves into a nearly closed state. The medication is injected into the softgel through the wedge. After injection, the wedge is taken away before the softgel is coated or sealed. In the end, the finished liquid gel capsule will be put aside to cool and settle.

Drying

A cool drum rotates fast during the drying process to help softgels congeal. The softgel goes through two steps afterward, tumble drying and drying tunnel. The purpose of drying is to remove extra moisture from the shell so that it will shrink and become firmer and more durable. A tumble dryer first removes nearly 25% of the moisture from the capsule in less than 45 minutes. The final drying step is in a tumbler machine. Softgel capsules are sent into the drying tunnel and laid on racks. They will be blown with rapid flows of air for 48 hours at a stretch. Through the above two steps, the liquid gel capsule is close to completion.

Further packaging

There are diverse machines for further packaging. The most suitable pharmaceutical packaging machinery is the blister packaging machine.

- A blister pack, also known as a unit-dose pack, is a perfect fit for pharmaceutical products such as capsules and tablets. It is easier to open medications and calculate doses with blister packs. They are applied to help the products defend against humidity and contamination so that their shelf life can be prolonged. The pharmaceutical blister packing machine packs the capsules mainly in two ways, thermoforming and cold forming. As for thermoforming, PVC sheets are heated and pressed into blister machines to shape into a proper form. However, cold forming applies aluminum-based laminate film to replace PVC film.

- Blister packaging applies a forming-filling-sealing process. First of all, a plastic film such as a PVC sheet is transferred forward and heated. Then on the softened plastic film, smooth blisters are made. After that, ingredients are filled into the blisters. The aluminum foil and the PVC are sealed up after the PVC blister is pressed into the mold. Some necessary information such as batch number and date will be printed on the back of the aluminum foil. The last step is to shear the blister as required. The scarp will be recycled for further usage.

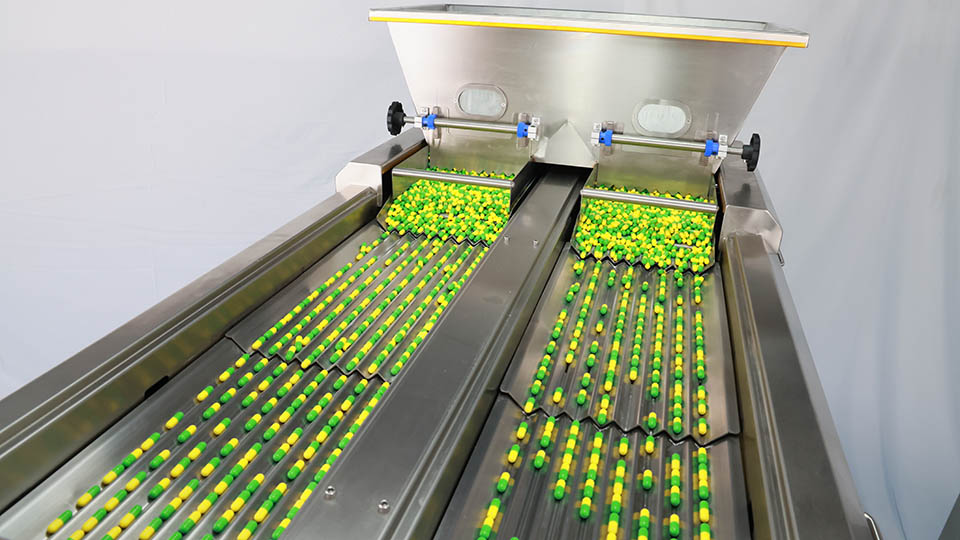

Machinery Involves

The whole process of manufacturing softgel capsules can be divided into four parts, capsule making, encapsulation, drying, and further packaging. For distinct functions, you may find different systems for soft capsule filling, pressing, counting, and packaging.

- The main structure of a liquid gel capsule filling machine contains a PLC control system, an empty capsule filling system, a liquid injecting system, a sealing system, a heat preservation system, and a drying system. The PLC control system is used for the real-time monitoring of the whole working process and gives alarms when the automatic capsule and material are short. The filling system maintains over 99.5% of the capsule loading rate through a vacuum positioning and separation mechanism. The injecting system controls the accuracy through a liquid adding system of servo motor and high-precision ceramic pump so that there is a less than 2% margin of error. In addition, the sealing system applies a servo motor to help the rubber wheel jog up and down and fine-adjust. The heat preservation system is placed in the liquid sealing tank to keep the viscosity of the capsule glue. Finally, the drying system applies a vertical suspension and free rotation structure, lessening the drying time by 50%.

- Rich liquid capsule filling machines are equipped with complete working sections to guarantee a smooth, continuous, and efficient line of production.

Conclusion

In this article, the reason why liquid softgel capsule is popular in pharmaceutical companies has been interpreted. The primary ingredients in softgel capsules are thoroughly introduced. Furthermore, four manufacturing processes are presented in sequence so that you can have a general overview of the production line. With the help of efficient gel capsule filling machines, the production of liquid softgel capsule can do more with less.