Medicine usually comes in the form of a capsule or tablet, whereas choosing whether capsule or tablet is not casual as you think. They are different in subtype, properties, and manufacturing process, leading to various pros and cons. An appropriate form guarantees a good effect of the medicine and promotes sickness recovery. So, what is the difference between a capsule and a tablet?

What Are Capsules?

(Source: Pixabay)

Types of Capsules

Generally speaking, capsules could be classified into two types, soft capsules, and hard capsules. Soft capsules are primarily applied for oils and for active ingredients that are dissolved or suspended in oil. In contrast, hard capsules contain powdered ingredients and miniature pellets. Each capsule is made up of a body that is filled with medicine powder and a cap that covers its body.

Capsule Properties

Capsules, no matter soft or hard, wear a shell, which is friendly to more forms of medicine, such as powder and liquid. What are capsule shells made of are they practical gelatin and starch? It is bigger in size. And it tastes flavorless. It could be colored. The medicine inside the capsule is without other mixture-like ingredients. It should be noted that patients should not open the capsule and eat inside medicine directly without the doctor’s advice

Manufacturing

Manufacturing Soft Capsule

To manufacture soft gelatin capsules, we usually use a rotary soft capsule filling machine. This machine contains a gelatin hopper, two gelatin rotary dies clinging to each other, a medicine liquid hopper, and a liquid pump.

First of all, pour the gelatin solution into a gelatin hopper and pour the medicine into the liquid hopper. When the machine starts, two gelatin rotary dies with lots of little circular dies, which are filled with little gelatin from the hopper, spin to form a spherical space. Thereinto, one rotary die carries half of the gelatin shell, and the other rotary die carries another half of the shell. These two halves will join into a whole shell for a soft capsule when the medicine liquid is pumped inside from the medicine hopper. With professional manufacturing knowledge, we can promise a precise joining and accurate medicine volume for each soft capsule.

Manufacturing Hard Capsule

To manufacture a hard capsule, gelatin solution, which is made from gelatin, color, opacifying agent, preservatives, and plasticizer, should be well prepared first. Then, dip metal pin molds into gelatin solution until coatings are formed. The next step is the rotation of the dip-coated pins and drying them in the chamber. Now, the coatings are ready and the machine is to strip them off the metal pin with a stripping knife. But the coatings are not in the right size as bodies and caps until the cutting blade trims them. Finally, joining bodies and caps together and empty capsules are ready for medicine filling.

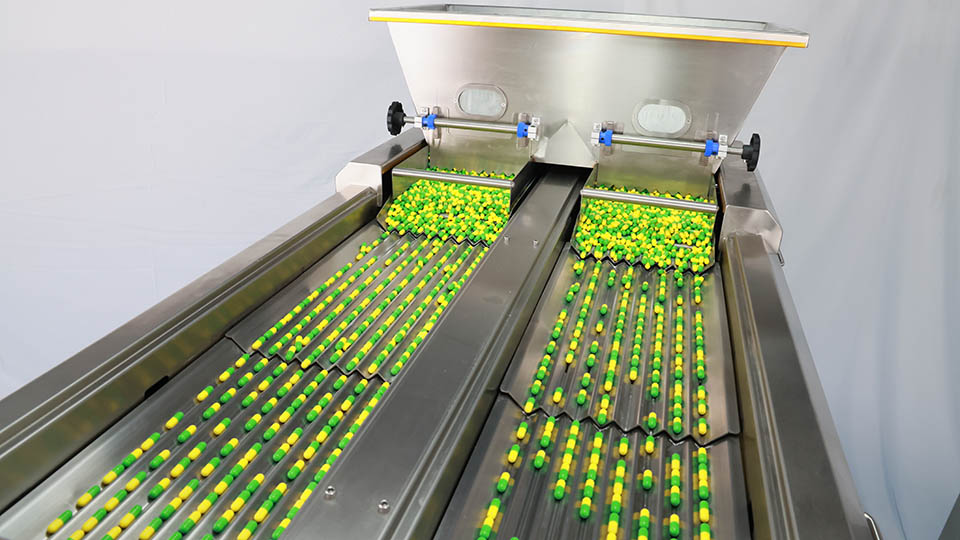

Nowadays, automatic empty shell machines and capsule filling machines have perfectly superseded the manual process in the modern pharmacy field. Manufacturing a completed capsule from gelatin dipping to medicine filling is an efficient and cost-saving thing now.

Pros&Cons

Due to the shell, the capsule can protect the medicine from the dissolution of gastric acid and release medicine at a specific point in the esophagus, even in the intestinal tract, which greatly promotes bioavailability. Second, bad-smelling or bad-tasting medicine can be isolated inside. Third, the capsule has a functional color coating. It contains shading ingredients so capsules are stable against sunlight. With color, it is very easy to identify, reducing the risk of taking the wrong medicine. If the capsule’s color is faded, the medicine is expired. Finally, the capsule is capable of carrying liquid in a specific dosage, providing convenience to patients.

However, it is too big to swallow by children of its unfriendly size. Also, it is expensive because of the complex manufacturing technique.

What Are Tablets?

(Source: Pixabay)

Types of Tablets

Tablets are mainly categorized into seven types, film-coated tablet, sugar-coating tablet, enteric-coated tablet, dispersible tablet, modified release tablet, prolonged-release tablet, effervescent tablet, lozenge, and sublingual tablet.

In particular, effervescent tablets are able to carry and release carbon dioxide after mixing water. And lozenges and sublingual tablets are used for medicine which should be released under the tongue or chewed in the mouth.

Tablets Properties

Tablet is a pressed solid mixture of medicine and inactive ingredient. Most inactive ingredient contains excipients, which strongly helps hold the tablet together. It is soluble in water. It tastes slightly bitter if there is no coating for the tablet. In terms of cost and manufacturing, it is cheaper and simpler than a capsule.

Manufacturing

Among lots of manufacturing techniques, wet granulation and dry granulation are the most popular method.

In the manufacturing of wet granulation, we need to produce soft materials first by mixing, granulation, drying, sieving, and mixing with glidant. In the second stage, we turn the soft material into a tablet by mixing, disintegration, lubricant, and compression. This manufacturing technique promises good mixing and good density of production.

In the manufacturing of dry granulation, there are two compression processes. In the first compression, we need to mix and compress all raw materials, containing the active ingredients, diluent binder, and lubricant, into a massive solid by roller compactor or tablet press machine. In the second compression, we need to smash, sieve, mix, and compress again. Compared with wet granulation, it is a simple and time-saving manufacturing technique.

When compression is finished, if necessary, the tablet is going to be coated by automatic coaters. According to the property of powder, you can choose sugar coating, enteric coating, or other.

Pros&Cons

For the factory, it can be easily produced in mass output in a limited time and cost. And it is easy to keep the hygienic condition in plants because of the simple producing process, so tablets can reach high-quality standards with ease.

For patients, tablets are more flexible in dosage against the doctor’s advice because it can be cut apart. Innovatively, the tablet offers a new form of containing acidic substances, giving patients a new way to access acidic substances. However, the patient should store the tablet carefully, or else it will get damp.

FAQ

(Source: Pixabay)

Which One is Safer? Capsules or Tablets?

In terms of swallowing, both capsules and tablets are safe for adults. Children should swallow medicines, especially big capsules, under the instruction of their parents, avoiding the risk of esophagus obstruction and even weasand obstruction. For syncopal patience, it is not recommended to give capsules or tablets unless there is a doctor’s advice.

In terms of protecting gastric mucosa, it is suggested that you should choose capsules. The shell of the capsule can isolate medicine, if it is an irritant, from gastric mucosa.

Which One Has Better Absorption? Capsules or Tablets?

Capsules are highly recommended when it comes to better absorption. Due to the manufacturing technique, there is no spare ingredient in the capsules, leading to easy absorption. Anyway, it can be absorbed just in the intestinal tract.

In terms of Manufacturing, Capsules vs Tablets Which is Better?

Manufacturing tablets is more efficient and controllable in quality. Anyway, we need to consider patience’s requirements and medicine’s properties, too.

Conclusion

(Source: Unsplash)

Although there are some differences between capsules and tablets, both of them are good oral carriers. With the popularity of automatic manufacturing, they come in more subtypes and can reach precise standards, providing better solutions for drug delivery.