DPH-270Max Blister Packaging Machine

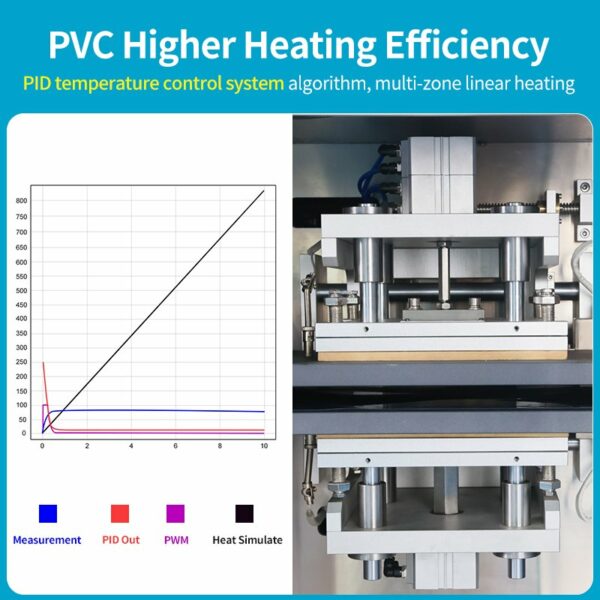

DPH-270Max Blister Packaging Machine involves the automated process of packaging products (such as tablets, capsules, or soft gels) into pre-formed blister cavities using a blister film, typically made of PVC or PET, and a backing material such as aluminum foil.

Forming the Cavity: The pre-heated film is drawn over a set of forming molds. Using a vacuum or mechanical pressure, the film is shaped into individual pockets or cavities that will hold the product.

Product Inspection (Optional): Some machines have an integrated inspection system to ensure the correct number and orientation of products are loaded into each blister.

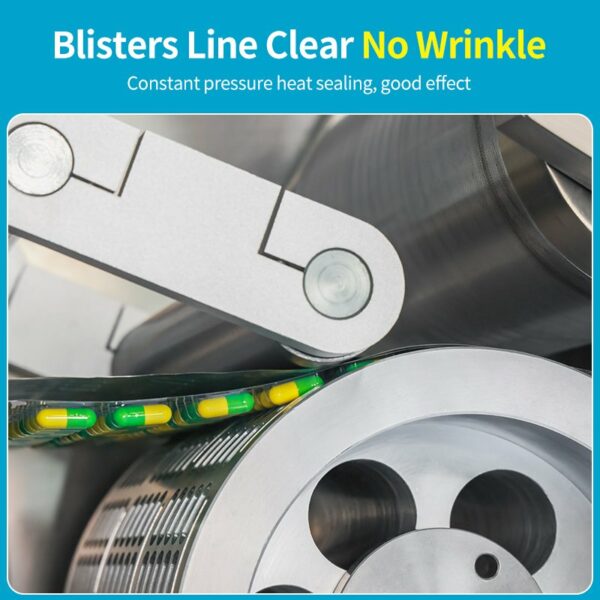

Aluminum Foil Backing: After the products are loaded, the blister film is moved to the sealing section. A backing material, usually aluminum foil, is unwound and placed over the formed blister pockets.

Blister Cutting: Once the blister packs are sealed, the individual blister packs are cut into separate units using a rotary die or guillotine cutter.

Specification:

Up to 27,000 blisters/mins

Applicable for tablets, capsules and medicine etc

15 Days Fast Delivery