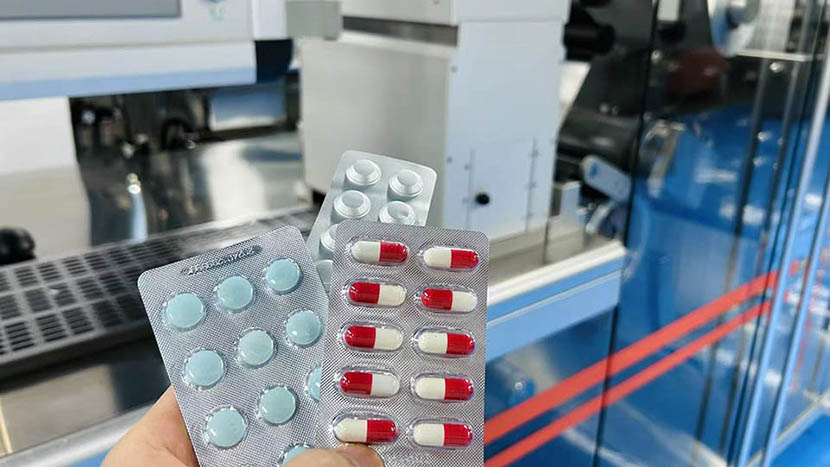

A blister pack, that familiar clear plastic shell seated on an aluminum backing, is a ubiquitous form of packaging designed for drug tablet protection, and unit-dose convenience. The machine that creates blister packs — a blister packing machine is a marvel of automation engineered to package a diverse range of everyday products including medication tablets, pills and capsules, effervescent tablets, and lozenges to more specialized items such as electronic cigarettes, syringes, and even large traditional medicine pills, into alu-plastic or alu-alu blister packs.

When it comes to operational speed, blister packaging machinery are broadly categorized into medium-low and high-speed models, with the latter capable of boosting production output by an impressive 2 to 6 times, making them the backbone of a high-volume blister packing line.

1.Types of Blister Pack Packing Machine

Based on equipment’s different operational speeds and heat sealing mechanisms, tablet blister packaging machines can be classified as follows:

1.1 Desktop Blister Packaging Machine: Compact and small-sized, this small blister packing machine can be placed on a desktop for operation, typically using a flat-plate forming principle and is suitable for laboratories, small pharmaceutical factories, or clinics. Features of this mini blister packing machine include a small size, high flexibility, and user-friendly operation, mainly used for small-batch trial production, blister sheet sample preparation, or teaching demonstrations, but it has a low production speed.

1.2 Flat Plate Blister Packing Machine: It is typically referred to a medium-to-low-speed blister package model. They use flat-plate molds to punch and form plastic or aluminum blister packs. It operates intermittently (stop-and-punch cycle), producing blister sheets with precise dimensions. This pill blister packing machine boasts a robust structure and high stability, suitable for packaging various irregular-shaped drug tablets, large pills, or products with special requirements for blister shape.

1.3 Roller Type Blister Packaging Machine: It is the primary model for high-speed blister pack packaging. If drug blister packaging requirement exceeds 200 blister packs per minute, this blister packing forming machine is typically chosen. Unlike the intermittent operation of a flat plate blister machine, a roller type blister packaging packing machine employs a continuous rotary motion for blister forming, filling, and sealing stations, ensuring smooth operation at high speeds, ideal for large-scale blister packing of single-variety products.

2.How to Choose between a Flat Plate and Roller Type Blister Package Machine?

When choosing between a flat plate and a roller type blister packing machine automatic, several key factors should be considered to match the right blister pack packaging technology based on your package characteristics, output targets, and operational flexibility.

In terms of blisterpak output, if your medical blister packaging requirements are moderate as 50 blister sheets per min, a flat plate capsule blister packing machine may suffice. However, for higher speeds such as 200 blister sheets per minute, a roller type automatic blister packing machine is more suitable due to its continuous motion and efficient handling.

Regarding product type, a roller type blister packaging packing machine is ideal for high-volume, uniform items like medicine pills and capsules and (e.g. 450 blister packs per min). A flat plate blister packing making machine offers greater flexibility for irregularly shaped products, such as vape pens or syringes, thanks to its intermittent motions and customizable molding stations.

About blister pack size and depth, a flat type blister sealing packing machine generally provides a larger blister pack forming area and deeper blister cavities. If your target blister pack length exceeds 280mm or the depth is over 16mm, a flat plate medical blister packaging model is recommended.

Considering mold changeover frequency and tooling costs, flatbed pharmaceutical blister packaging equipment allows easier mold adjustment and is better for short runs, while a roller-type pharmaceutical blister packing machine excels in long, high-speed blister packs packaging with lower costs per unit.

3.How Is High-Speed Blister Pack Packaging Achieved?

In automated pharmaceutical blister packaging, the core choice often lies between a traditional flat plate plastic alu blister packing machine VS a modern roller type blister packager. For the pursuit of high speed and mass output, a roller-type plastic aluminium blister packing machine is key to optimizing your pharmaceutical packaging line.

3.1 Production Output and Speed

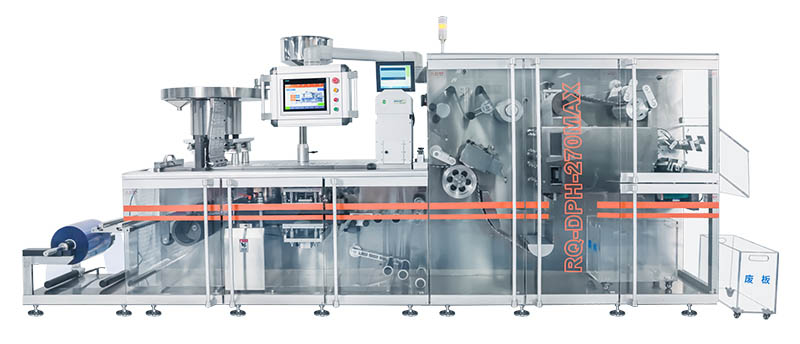

Pursuing higher speed and greater output, a roller type blister foil packing machine is a preferred option, for it utilizes a continuous rotary motion. The plastic PET or PVC film is thermoformed and the lidding aluminum foil is sealed between rotating rollers. This seamless blister pack packaging allows for much higher operational speeds, often exceeding 100 cycles/min. For example, the RD DPH 270Max roller type aluminum plastic blister packing machine reaches a maximum output of 450 blister plates per min.

In contrast, a flat plate automatic tablet capsule blister packing machine operates with a intermittent, start-stop motions. The forming and sealing stations move up and down, limiting the maximum speed. Flatbed blistering machines are robust but typically cap at around 30-40 cycles/min.

3.2 Continuous Heat Sealing

The continuous heat sealing mechanism is the defining feature of a roller-type full automatic blister packing machine and is the primary reason for the superior speed and high-output blister packaging capabilities. Unlike intermittent heat sealing, this method facilitates non-stop, streamlined medical blister packaging that boosts overall efficiency.

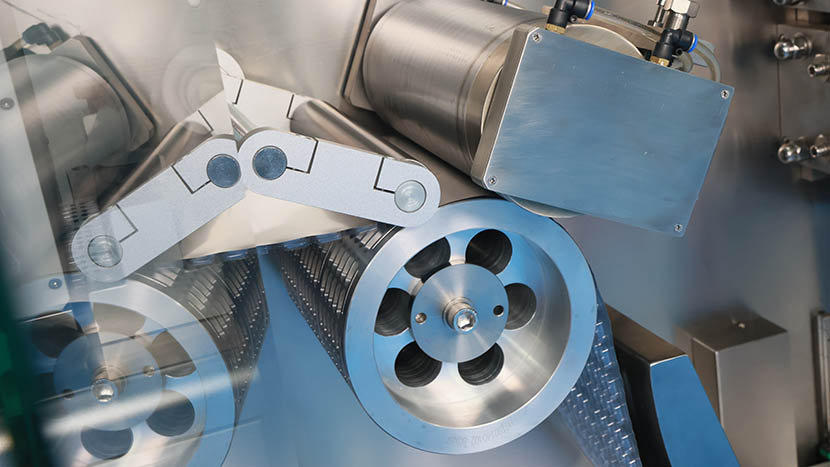

The principle behind this productivity gain is simple: constant motions. In a roller type hot sealing machine for blister packing, the formed PVC blister web and the lidding material (typically aluminum foil) are drawn together between two continuously rotating rollers. One roller is heated, applying consistent pressure and temperature to seal PVC and alu layers, while the opposing cooled roller immediately solidifies the PVC-Alu layer bond.

This seamless process means the medical blister packing machine can form blisters, fill blister cavities with pills and capsules, seal them, and cut blister packs in one uninterrupted, linear motion. There are no pauses, allowing the medicine blister pack packing machine to operate at much higher speeds without risks of material overheating from prolonged contact with a static heat source.

Advantages of continuous heat sealing stand in stark contrast to the intermittent heat sealing found in a traditional flat type medicine blister packing machine, in which the PVC and aluminum films must stop moving completely for a flat, heated plate to descend, press down on the sealing area, and then retract before the PVC-alu layer film can advance again. This start-stop cycle limits speed, creates a production bottleneck, and subjects the aluminum foil lidding material to partially intense, localized heat with each cycle, which can occasionally lead to weak seals.

Thanks to continuous heat sealing mechanism, roller type pill blister medicine packing machine eliminates these jerky movements, distributing heat and pressure evenly for more consistent seal quality. By smoothing out the pharmaceutical blister packaging into a constant flow, a roller type drug blister packaging model achieves greater gains in packaging speed, throughput, and operational smoothness.

3.3 Continuous Roller Traction Mechanism

A key technological advancement that sets high-speed roller-type blister packaging machines apart is their use of a continuous roller traction mechanism. Unlike the intermittent start-stop motion found in a flat-plate vitamin capsule blister packing machine, this distinguished mechanism employs a set of precisely engineered rollers that grip blister packaging material—typically a PVC-Alu layer—and pull it through forming, filling, and sealing stations in a single, smooth, and uninterrupted motion. This fundamental difference in material handling is the core reason for better performance and efficiency.

The continuous traction motion is also a principle behind a roller-type blister pack machine’s ability to operate at higher speeds and achieve greater overall output. By eliminating the inertial force and stress placed on the package material during the rapid acceleration and deceleration of an intermittent traction cycle, the auto blister packing machine can run faster and smoother. In contrast, the relatively jerky traction motion of a flat-plate automatic blister medicine packing machine inherently limits its max speed to prevent package material misregistration.

Another benefit of this continuous traction is the achievement of near-zero-error registration accuracy. Because the package material (PVC films and aluminum foil films) is in constant motions, there is no inherent slippage or positional loss that can occur when a roller-type alu-pvc blister sheet packing machine abruptly stops and starts again, ensuring every blister cavity and every section of the lidstock film is perfectly aligned at each processing stage, critical for blister pack integrity.

A direct advantage of this is that if the machine must stop for any reason, the packaging material does not retract or lose its position. This “no-backtracking” feature allows for quicker and easier restarts, minimizing material waste and reducing downtime.

4.About Package Material Waste & Saving

Understanding working theories of a high-speed pill capsule blister packager, you can know that a roller type capsule tablet blister package machine is equivalent to a high-speed model. In addition to superior speed, a roller-type automatic alu pvc blister packing machine enjoys an advantage of saving more package materials.

Compared to continuous traction motions of a roller-type blister medicine packing machine, intermittent motions of a flat plate blister packing and sealing machine create more material stress and require larger distance between blister sheets to accommodate the mechanical movement, leading to more trim waste—the unused material between blister packs and at edges.

A roller type capsule pill blister packing machine has a much shorter and more controlled material path, and its continuous feed and precise registration ensure minimal material stretch and a narrower trim margin. Therefore, this precision translates to less plastic and aluminum foil consumed per produced blisterpak.

According to industrial statistics issued by Ruida Packing Machinery, if 75.6 million blister packs are produced per year, a roller type capsule tablet blister packing machine can save 200,000 CNY of plastic and aluminum foil compared to a flat plate tablet blister packing machine.

บรรทัดสุดท้าย

A roller type pharma blister packing machine is a champion of saving material and cost. While its initial investment is higher, the long-term savings are substantial:

●Reduced Raw Material Use: It can achieve material savings of 5% to 15% compared to a flat plate alu pvc blister packing machine, a massive reduction over time.

●Higher Output: Its superior speed means you produce more blister packs in less time, lowering the cost per unit.

●Less Energy Consumption: The continuous motion is often more energy-efficient than the constant stopping and starting of a flat plate model.

For high-speed, high-volume production where minimizing material waste is a priority, a roller type blistering machine is the superior, cost-effective choice. In comparison, a flat plate automatic pill blister packing machine remains a valuable asset for smaller batches or products requiring specialized tooling, but it comes with higher operational waste.