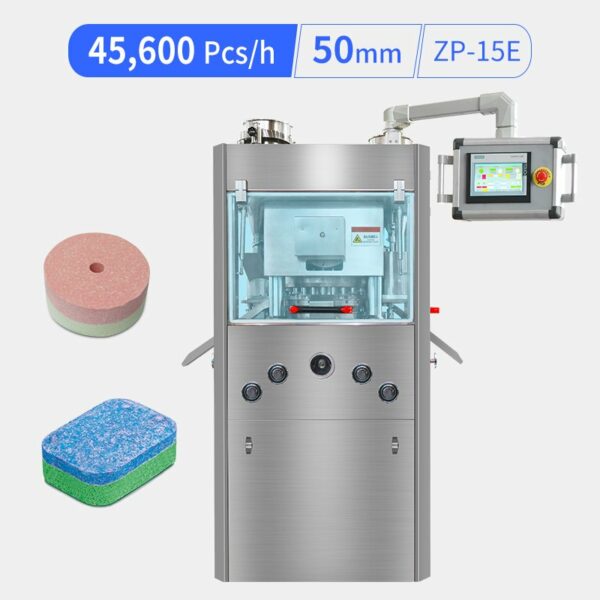

Two Layers Tablet Press Machine

Two layers tablet press machine is widely used in the pharmaceutical, nutraceutical, and chemical industries, particularly when tablets require multiple active ingredients or layers. Here are some of its key applications:

Vitamins and Supplements: Often used to combine vitamins, minerals, and other supplements in a single tablet, improving convenience and

Specialty Chemicals: Useful for producing tablets that require multi-layer structures to keep components separate until use.

Household Products: Multi-layer tablets are sometimes used in cleaning and disinfection products, where each layer has a different function or releases at different times (e.g., dishwasher tablets).

Would you like more information of tablet making machine?

Specification:

Up to 45,600pcs/h

Max. dia. of tablet 50mm