Medicine Capsule Making Machine

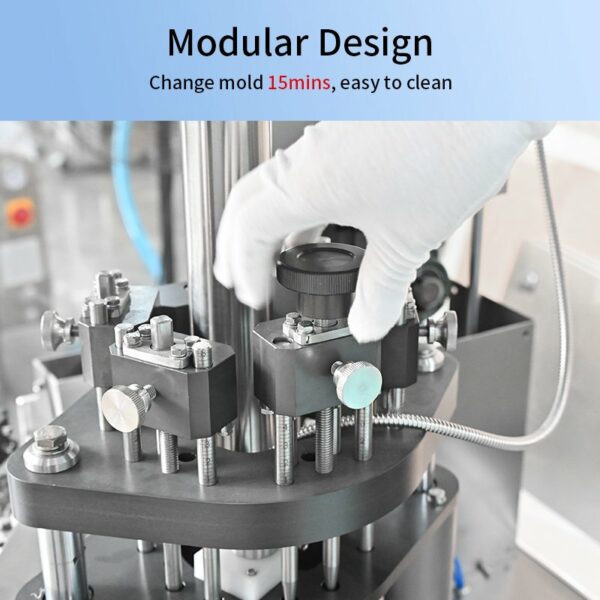

Medicine capsule making machine works by automating the process of filling hard with powdered, liquid, or pellet-based substances.

Capsule Separation: Capsules (usually two-piece capsules) are fed into the machine through a hopper.

Capsule Filling: The machine uses a dosator (a metering system) to fill the capsule body with the desired material (powder, pellets, or liquids). This could be done using a vibrating tray or a screw feeder to ensure accurate dosage.

Filling Process:The material is dosed into the capsule body, and sometimes, a compaction system is used to settle the material and ensure uniformity. The machine adjusts the filling amount based on weight control or volume measurement.

Ejection and Inspection: The completed capsules are ejected from the filling plate.

Specification:

Up to 24,000 pcs/h

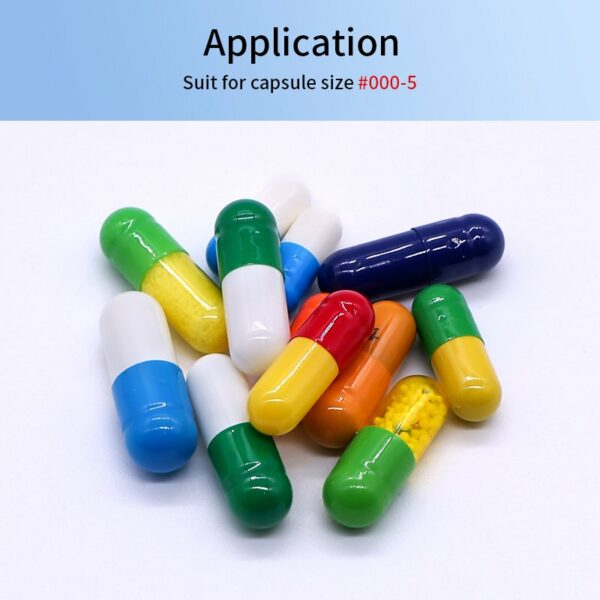

Appplicable for capsule size #000 ~ 5

Suitable for powder, granule, pellet