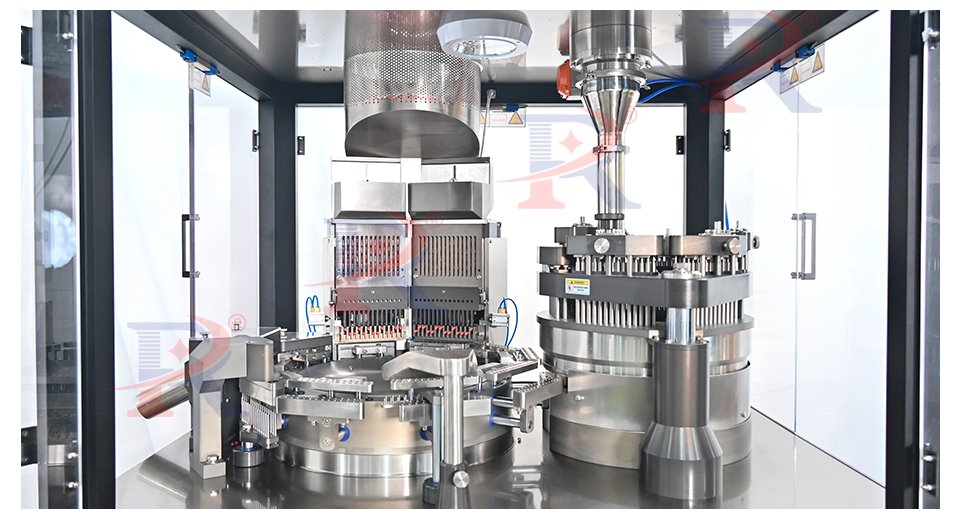

How to maintain the capsule filling machine has always been big problems in the industry. This article will solve the problems you encounter when using the capsule filling machine, mainly from the three aspects of overall maintenance, turntable maintenance, and filling station maintenance.

Overall Maintenance of Capsule Filling Machine

Maintaining capsule filling machine is essential to ensure its longevity and optimal performance. Mainly carry out maintenance in 4 aspects: daily, weekly, monthly and annual:

1.Daily Maintenance:

Cleaning: Clean the capsule filler machine after use to remove powder or capsules residues. Use a soft brush and vacuum to clean hard-to-reach areas.

Inspection: Inspect for any visible wear and tear or damage to parts. Check for any loose screws or bolts.

Apply food-grade lubricant to running parts to prevent wear and tear, as specified in the manufacturer’s manual.

2.Weekly Maintenance:

Deeper Cleaning: Disassemble parts such as the dosing disc, tamping pin, and capsule magazine for a more thorough cleaning. Use appropriate cleaning solutions that do not corrode or damage the machine components.

Component Check: Inspect components like the sorting and feeding mechanisms, capsule body, and cap handling sections for any signs of wear or misalignment.

Lubrication: Re-lubricate parts as required, following the manufacturer’s recommendations.

3.Monthly Maintenance:

Detailed Inspection: Conduct a detailed inspection of all mechanical and electrical components. Look for signs of corrosion, wear, or potential failure points.

Alignment and Calibration: Check the alignment and calibration of the machine to ensure accurate filling. Adjust settings as necessary to maintain precision.

Replace Worn Parts: Replace any parts showing signs of significant wear to prevent breakdowns during operation.

4.Annual Maintenance:

Professional Servicing: Schedule a professional servicing to thoroughly inspect and service the machine. This may include replacing major components and recalibrating the entire system.

Software Update: If your machine includes software, check for updates or upgrades that may improve performance or add new features.

5.Common Issues:

Inconsistent Fill Weights: Check for blockages or residues in the dosing mechanism. Ensure proper calibration and alignment of the filling and tamping components.

Capsule Defects (e.g., dents, cracks): Inspect the sorting and feeding mechanisms for any misalignment or damage. Check whether the capsules have been stored in a humid environment.

Machine Stoppages or Jamming: Check for foreign objects or material build-up in the machine.

By adhering to these maintenance guidelines, you can ensure your automatic capsule filling machine remains in good working order, reducing downtime and extending its operational life.

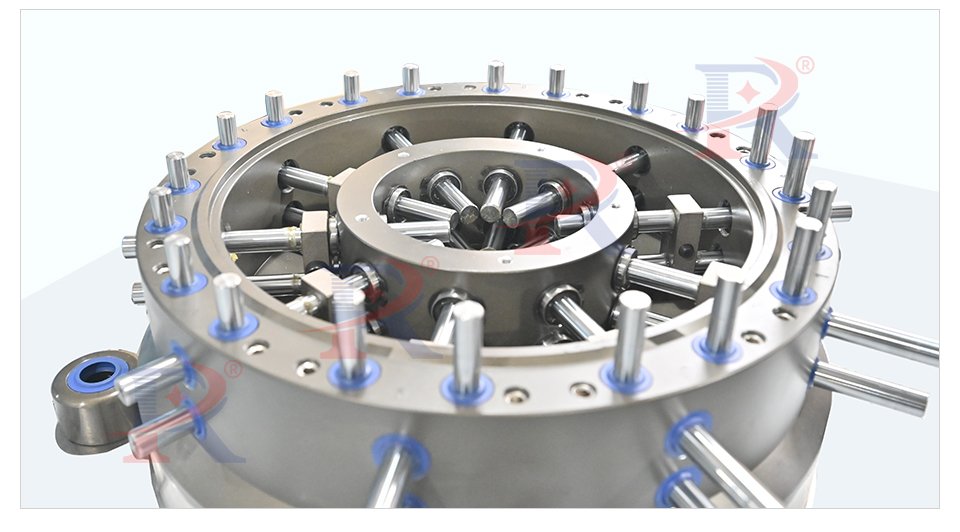

Turntable Maintenance of Capsule Filling Machine

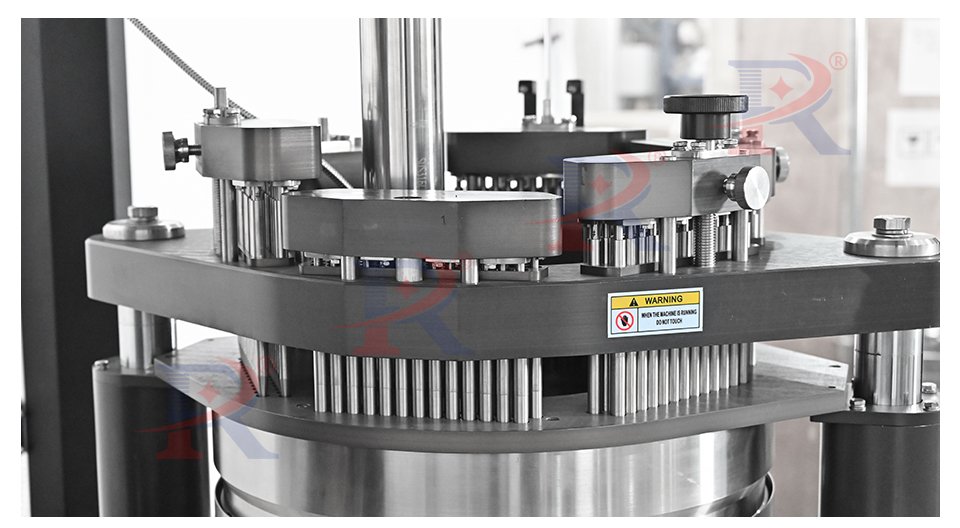

Maintaining the turntable of a NJP series capsule filling machine is crucial for ensuring smooth operation and accuracy.

1.Turntable Maintenance Steps

Power Down: Ensure the machine is turned off and unplugged before beginning maintenance.

Safety first: Take safety precautions before starting the inspection and wear goggles and safety gloves.

Surface Cleaning: Wipe down the turntable surface with a clean, dry cloth to remove any powder residue or debris.

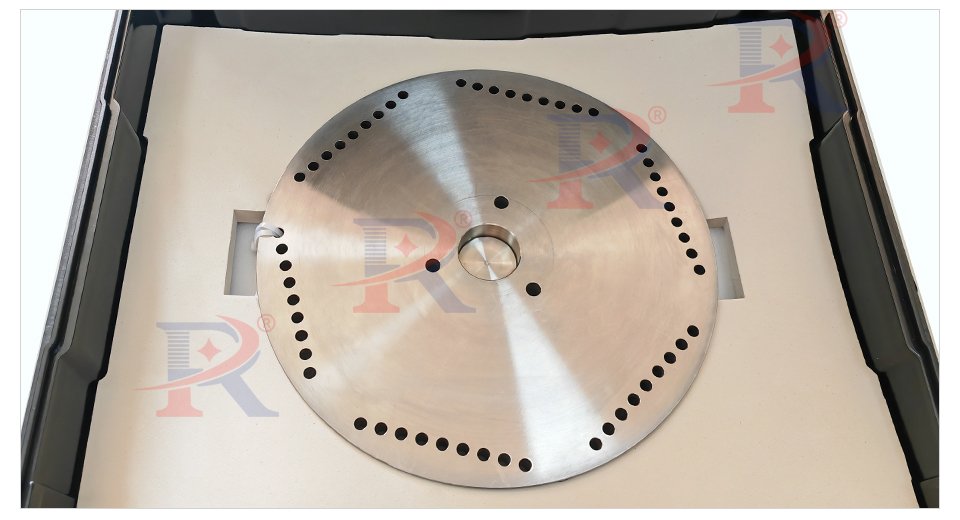

Surface Inspection: Inspect the turntable for visible signs of wear, scratches, and residue buildup. Look for cracks, dents, or other deformities that could affect performance.

Deeper Cleaning: Use a soft brush or vacuum to clean around the turntable, focusing on grooves and crevices where powder may accumulate. If needed, use a mild, non-corrosive cleaning solution to remove stubborn residues.

Check for Alignment: Ensure that the turntable is properly aligned with other components of the machine. Misalignment can lead to uneven filling and capsule defects.

Inspect Bearings: Check the bearings for signs of damage. Replace worn parts for stable operation.

Lubrication: Apply food-grade lubricants to the turntable bearings and gears as specified in the manufacturer’s manual. Proper lubrication can effectively prevent wear of bearings and gears.

Calibration Check: Verify that the turntable is rotating at the correct speed and is synchronized with other machine components. Adjust the settings as necessary.

Component Replacement: Proactively replace any parts that show signs of significant wear, even if they are not yet causing issues. This can prevent unexpected downtime.

2.Common Issues

Turntable Not Rotating Smoothly:Check for debris or residues that may be causing friction. Ensure that the bearings are properly lubricated. Inspect the motor and drive system for any issues.

Unusual Noises: Listen for grinding or squeaking sounds, which may indicate a need for lubrication or bearing replacement.

By regularly maintaining the turntable of your encapsulation machine, you can ensure consistent performance, reduce downtime, and extend the machine’s operational life.

Filling Station Maintenance of Automatic Capsule Filler

Maintaining the filling station of a capsule filling machine is crucial to ensure accurate dosing and reliable operation.

1.Filling Station Maintenance Steps

Check Seals and Gaskets: Check Seals and Gaskets: Inspect Oil and dust proof seal or damage. Replace any that are compromised to prevent leakage and contamination.

Detailed Cleaning: Perform a more thorough cleaning using appropriate, non-corrosive cleaning solutions. Make sure the filling rod and metering disc are dry before reassembly.

Inspection of Moving Parts: Inspect moving parts such as filling pins, dosing disks, and powder delivery mechanisms for signs of wear or damage. Replace worn parts to maintain precise operation.

Lubrication: Apply food-grade lubricants to the specified moving parts, following the manufacturer’s guidelines. Proper lubrication reduces friction and wear.

Calibration Check: Verify and, if necessary, recalibrate the filling station to ensure accurate dosing.

Component Replacement: Proactively replace parts that are nearing the end of their service life. This includes dosing disks, filling pins, and other critical components.

2.Common Issues

Inconsistent Fill Weights: Check for blockages in the powder hopper or dosing mechanism. Make sure the metering disc and fill rod are aligned. Inspect for damage to the dosing components and change if necessary.

Powder Leakage: Inspect seals and gaskets for damage and replace if necessary.

Jamming or Stoppages: Check for foreign objects or powder build-up causing the jam. Inspect moving parts for wear or damage and ensure they are properly lubricated.

3.Cleaning Procedure for Filling Station Components

Disassemble the Filling Station: Follow the manufacturer’s instructions to safely disassemble the filling station.

Dosing Disks and Tamping Pins: Use a brush and appropriate cleaning solution to remove powder residues. Rinse with water and dry thoroughly.

Powder Hopper and Delivery Mechanisms: Wipe down with a damp cloth and a mild cleaning solution. Ensure all powder residues are removed.

Seals and Gaskets: Clean with a mild detergent solution and inspect for any signs of wear or damage.

Reassemble and Test: Carefully reassemble the filling station components, ensuring all parts are correctly aligned and tightened. After the machine is checked, start it first. If there is no problem, start it automatically to avoid interruption.

By following these maintenance steps, you can ensure that the filling station of your capsule filling machine operates efficiently, accurately, and with minimal downtime.

According to the above maintenance steps, avoid some common problems and effectively extend the life of the machine. If you have any questions about capsule filling machine, please contact Ruidapacking.