High Speed Capping Machine

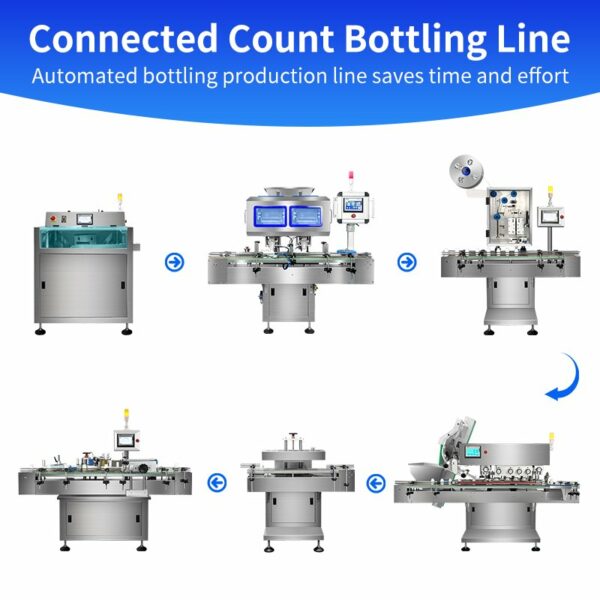

High speed capping machine is used in various industries to place and secure caps on containers quickly and efficiently.

Cap Chute: Sorted caps are transferred to a cap chute, which guides them to the capping head. The chute ensures a continuous and smooth supply of caps to the capping mechanism. Containers are accurately positioned under the capping head using a star wheel or timing screw.

Torque Adjustment: The capping machine is equipped with a torque control system to ensure that caps are applied with the correct amount of force. This prevents under-tightening or over-tightening, ensuring a secure seal without damaging the container or cap.

Quality Control: After capping, containers pass through an inspection station. Sensors or cameras check for proper cap placement and tightness. Defective containers are automatically rejected from the line.

Outfeed Conveyor: Properly capped containers are transported to the outfeed conveyor, where they are collected for further processing, such as labeling or packaging.

Specification:

Up to 120 bottles/mins

7 days delivery

Suitable for wide range of bottle shapes and caps