Film-coated tablets are everywhere—from everyday supplements to prescription solid doses—because a well-applied coat makes tablets easier to handle, easier to take, and more consistent in appearance. The catch is that coating sits right at the intersection of core tablet quality, coating formulation, and equipment performance. When any one of those drifts, the result is rarely subtle: rough texture, uneven color, sticking, or defects that slow inspection and packaging.

This article walks through tablet film coating with a practical focus: what it is, why it’s used, what’s typically inside a coating system, and how a tablet coating machine / tablet coater influences outcomes—especially for teams who are new to coating but want reliable, repeatable batches.

Tablet Film Coating Basics: What It Is

Tablet film coating is the controlled application of a thin, polymer-based layer onto the surface of tablets. In most production setups, tablets tumble inside a rotating pan while a spray system applies a coating liquid. Controlled inlet and exhaust air then remove moisture so the liquid turns into a continuous film rather than a tacky layer.

What film coating is

- A thin, uniform film that reduces dusting and scuffing during handling and improves appearance.

- A common route for taste masking and smoother swallowability.

- A process where the tablet coating equipment matters: spray quality, airflow balance, and drying capacity often decide how forgiving the run is. (PMC)

What film coating is not

- Not automatically enteric coating. Enteric film coatings are a specific functional class designed to resist stomach conditions and release later.

- Not sugar coating. Sugar coating is thicker, slower, and changes size/weight far more.

- Not a cover-up for weak cores. Dusty tablets, brittle edges, or wide hardness variation usually show up more clearly after coating.

Where it fits in the manufacturing flow

Coating sits after compression and before final packaging. If your upstream compression step isn’t stable—things like friability, dust, or hardness variation—coating will usually expose it fast. That’s why teams often review their rotary tablet press machine settings and core tablet quality before they spend time “tuning” the coater. When coating is stable, downstream steps typically run smoother—less chipping on transfers and fewer appearance rejects in blisters or bottles.

Why Manufacturers Coat Tablets

Film coating isn’t only about looks. Teams use tablet film coating because it can improve manufacturability, patient experience, and (sometimes) performance.

Common reasons include:

- Appearance and identification: consistent color and finish, easier visual inspection.

- Handling protection: less dusting, less abrasion, fewer edge chips during transfer.

- Taste/odor masking: especially relevant for bitter actives and many nutraceuticals.

- Environmental protection: added resistance to humidity, oxidation, and light exposure (to a point).

- Functional goals (when needed): delayed release (enteric) or modified release systems—these usually have tighter requirements than a standard immediate-release film.

One practical rule: coating improves what’s already stable. If your core tablet is dusty, fragile, or inconsistent, the coating stage tends to amplify that.

What’s in a Film Coat

Most coating systems look complicated on paper, but the roles are simple when you group them by function. Film coating formulations typically include a polymer plus additives that help film formation and processing (plasticizers, colorants, anti-adherents, etc.).

| Component (simple name) | What it does | What you’ll notice if it’s off |

| Polymer (film former) | Builds the film layer | weak adhesion, cracking, poor protection |

| Plasticizer | Keeps the film flexible | brittle coat, cracking, peeling |

| Pigment/opacifier | Color + light protection | uneven color, poor hiding |

| Anti-tack / anti-adherent | Reduces sticking | picking/sticking, rough surface |

| Solvent system (often water) | Carries solids to the surface | slow drying, overwetting risk |

A quick beginner-friendly takeaway: water-based systems can be simpler from a safety standpoint, but they often demand stronger, more stable drying capacity from the coater.

How the Film Coating Process Works (Step by Step)

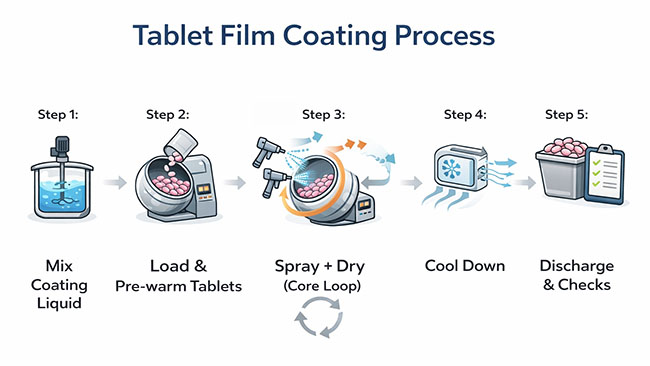

Even with different coating machine designs, the workflow is consistent across most coaters:

1) Prepare the coating liquid

Mix and disperse solids properly. Poor dispersion can clog nozzles, create spray instability, and lead to speckling or roughness.

2) Load tablets and stabilize movement

Before spraying, you want stable tablet motion and a stable bed condition. Spraying onto a cold, poorly moving bed is a common fast track to sticking.

3) Spray + dry (the core loop)

Most coating problems come down to balance:

- Too wet → overwetting → sticking/picking/twinning

- Too dry → droplets dry mid-air → roughness / poor film formation

- Poor mixing → uneven exposure → color variation

4) Cool down and discharge

Cooling isn’t a formality. Discharging warm, slightly tacky tablets can create scuffing and marks in bins and transfers.

5) In-process checks

At minimum, teams track:

- weight gain trend (build rate consistency)

- appearance (early signs of sticking, twinning, roughness)

- process stability (spray behavior, exhaust conditions)

If you’re setting up coating in a more “modern” way, it’s worth knowing that regulators explicitly encourage improved process understanding and measurement where it makes sense (this is the spirit behind PAT and quality-by-design frameworks). (U.S. Food and Drug Administration)

Coating Machine Types (and How to Pick the Right One)

Coaters differ, but the fundamentals don’t: mix tablets, apply droplets, remove moisture, repeat—consistently.

Perforated pan coater (common choice for tablets)

Pros

- efficient airflow and drying

- more predictable scale-up for many tablet products

- often better uniformity control

Cons

- higher cost than basic pans

- more systems to maintain (air handling, filters, spray)

Conventional pan coater (still used in some settings)

Pros

- simpler and often cheaper

- can work for certain products and smaller operations

Cons

- drying and uniformity can be harder to control

- can be less forgiving with higher-solids or water-based systems

Fluid bed coaters (more common for pellets/granules)

Most common when the substrate isn’t a tablet (pellets, granules, multiparticulates), or when very uniform coating is needed on small particles.

A practical buying tip

When you’re evaluating a tablet coating machine, don’t only ask “capacity.” Ask how the supplier proves repeatability: clear acceptance criteria, documented run data, and checks that are long enough to expose drift.

For example, Ruidapacking’s outgoing verification can include a 24-hour continuous run plus an additional high-load window—use that style of evidence as your benchmark for seriousness (documented, long enough, repeatable), not as a checkbox.

Core Tablet Checklist Before Coating

If you want calmer coating runs, start with the core:

- Friability and edge strength: fragile edges chip, and chips trigger surface defects.

- Dust level: dusty tablets stick more easily and can create rough, speckled coats.

- Hardness consistency: large variation often shows up as uneven abrasion and uneven finish.

- Shape and embossing: sharp edges and deep logos increase the risk of logo bridging and edge defects.

- Lubricant residue: too much can reduce adhesion; too little can increase friction and chipping.

You don’t need perfect tablets—just tablets that behave consistently enough for the film to build evenly.

Key Parameters Explained

If you only remember one idea: most coating issues are driven by overwetting or over-drying.

Spray-related

- Spray rate: too high → overwetting → sticking/picking

- Atomization air / droplet size: poor atomization creates large droplets that overwet local areas

- Gun position and pattern: affects coverage and local wetting

Air and temperature

- Inlet air temperature / airflow: defines drying capacity

- Exhaust conditions: tell you what’s really happening; instability often signals instability in drying

- Bed temperature: a practical indicator for sticking risk

Mechanical

- Pan speed and load: impacts mixing; poor mixing is a fast path to non-uniformity

If you ever move toward more structured process development, the “design space / control strategy” language you hear in industry comes from well-known QbD guidance.

Common Defects and Quick Fixes

A faster way to troubleshoot is: identify what you see → adjust 1–2 variables → observe trend.

| What you see | Common name | Likely cause | Practical first moves |

| Tablets stick together | Twinning | overwetting + weak mixing | reduce spray rate; increase drying slightly; adjust pan speed/baffles |

| Film lifts or flakes | Peeling | poor adhesion, brittle film, dusty cores | improve dedusting; avoid harsh early drying; review solids/plasticizer |

| Rough “pebbly” surface | Roughness / orange-peel-like finish | droplets drying in air, poor atomization | improve atomization; tune inlet temp/airflow; adjust gun position |

| Film pulls off small spots | Picking | local overwetting + sticking | reduce spray; rebalance airflow; watch bed temperature |

| Logo looks filled in | Logo bridging | high viscosity/solids, overwetting in emboss | improve atomization; lower viscosity/solids; reduce local overwet |

(These defect patterns and the “wet vs dry” balance are discussed widely in peer-reviewed coating literature.)

QC: What “Good Coating” Means in Practice

Quality checks don’t need to be complicated to be useful.

Weight gain as a practical anchor

Many products monitor percent weight gain as a simple, actionable proxy for coating build. Published studies often describe film coating levels in the low single-digit range depending on purpose (example: 1–3% w/w in a film-coating study).

Uniformity and appearance

- consistent color and sheen

- no clusters, no rough patches, minimal defects

- stable finish after normal handling (bins, transfer, packaging)

Performance checks (high level)

Depending on coating purpose:

- disintegration/dissolution behavior (especially for functional coatings)

- stability expectations (appearance/integrity over time)

FAQ

1) What is tablet film coating?

A controlled process that applies a thin polymer-based film to tablets to improve handling, appearance, and sometimes protection or release behavior.

2) Is film coating the same as enteric coating?

No. Enteric coatings are a specific functional class designed to resist stomach conditions and release later.

3) Why do tablets twin during coating?

Most often it’s overwetting plus insufficient mixing. Start by reducing spray rate and improving drying balance.

4) What should I change first when defects appear?

Start small: spray rate, atomization quality, and airflow/temperature balance—avoid changing five things at once.

5) Do I need a perforated pan coater for tablets?

Not always, but stronger airflow control and drying capacity typically make runs more forgiving and repeatable.

6) Can coating fix chipping or dusty tablets?

Usually it makes those problems more obvious. Improve the core tablet first (friability control, dedusting, hardness consistency).

7) What should I ask when buying a tablet coater?

Ask about spray system design, drying capacity, cleaning/changeover, and how they prove performance (clear FAT/SAT criteria and documented run data). You can also compare coater options alongside upstream compression on a tablet press machine and downstream packaging like blister packing machines

8) How does coating affect packaging?

Stable coating reduces scuffing and appearance rejects and helps tablets survive transfers into bottles or blisters.

Closing thought

Once you understand the balance between spray, mixing, and drying, tablet film coating stops feeling mysterious. It becomes a controllable operation—where consistent core tablets, a stable process window, and a well-matched coater setup make results repeatable instead of “operator-dependent.”

References

- U.S. FDA: Process Analytical Technology (PAT) guidance (framework for improved measurement and control). (U.S. Food and Drug Administration)

- ICH Q8(R2): Pharmaceutical Development (QbD concepts relevant to process understanding and control strategies).

- Peer-reviewed review on pharmaceutical film coating (definitions, benefits, formulation components).

- Peer-reviewed review on non-destructive film-coating analysis and the importance of thickness/uniformity.