With over 20 years of hands-on experience in capsule filler machinery, I’ve encountered and resolved numerous operational issues. A low-quality capsule powder filling machine often suffers from problems such as missing capsules during capsule dispensing process, and improper capsule locking. These flaws not only impact efficiency but also final product quality. Hereby I will break down these common challenges and offer practical solutions to help you operate your capsule filling machine filler with greater confidence and ease.

How Does A Capsule Filling Machine Work?

Before handling issues of operating an automatic capsule filler filling machine, we are supposed to understand the working theory of the machine’s processing stations.

An automatic capsule filling machine automates the precise pharmaceutical ingredient filling into every two-piece hard gelatin capsule, boosting production output and ensuring dosage accuracy compared to manual capsule filling. Its core function is to seamlessly perform a series of operations to form closed capsules filled with powder or granules ready for packaging.

The capsule filling process begins at the capsule loading station, where empty gel capsules are poured into a hopper. These capsule shells are then oriented and fed into a capsule feeding module. Next, capsule separation occurs, where the upper capsule cap and the lower capsule body are pulled apart; capsule bodies remain in the lower bushing while capsule caps are held in the upper bushing. Now-empty lower bodies move to the capsule powder filling station, where they are filled with a precise dose of formulation via a dosing disc and powder dispensing rods.

Following capsule filling, the capsule making machine progresses to rejection of unqualified capsules, where any damaged, unseparated capsules are automatically removed from the cycle. Finally, the capsule locking station rejoins the filled capsule body with its cap, applying gentle pressure to ensure capsules are securely closed. Finished capsules are then discharged at the outputting station.

What Are Common Issues and Their Solutions When Using A Capsule Machine?

Operating an automatic hard capsule filling machine can present some recurring challenges. Below, I explore these common issues from capsule missing, unsuccessful capsule separation to capsule sealing failures, and provide practical solutions and maintenance advice to keep your capsule making smooth.

Issue 1: Missing Pieces in Capsule Feeding Process

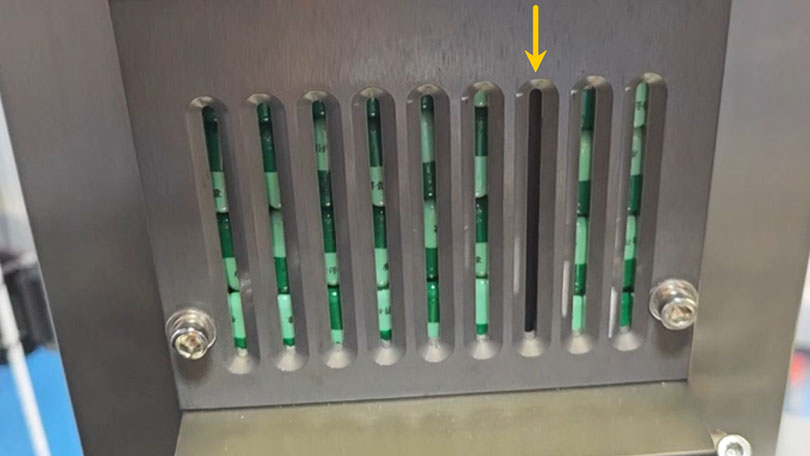

At the hard capsule feeding stage, empty capsules are loaded into a hopper and then distributed into capsule dispensing tubes. You may encounter the complete absence of gelatin capsules in one or more tubes, often due to damaged or irregular capsules blocking passages. Damaged capsules, such as crushed ones, missing caps, or improperly separated capsule halves, can obstruct capsule feeding tubes, leading to capsule feeding/dispensing failures.

To solve this, you should first inspect empty capsules for visible defects and remove any flawed one. Then, switch the gel capsule filling machine to jog mode and raise the capsule feeding module to its highest position, allowing access to capsule conveyor tubes so that any stuck capsule can be removed manually.

A fine metal probe can be used to check for and push out stuck pharmaceutical capsules. Alternatively, rotating the switch of capsule dispensing tubes can clear all medical capsules in tubes at once, ensuring pathways are clear before restarting your fully automatic capsule filling machine.

Additional measures include maintaining a consistent ambient humidity level to prevent gel capsule deformation. What’s more, establishing a routine cleaning and inspection plan for capsule feeding modules can further minimize the risk of missing capsules.

Issue 2: Capsules Failing to Enter Mold Holes

During capsule feeding, hard-shell capsules are supposed to move along with the capsule feeding module and properly enter holes in upper and lower molds. However, sometimes powder capsules may fail to be seated into mold holes correctly.

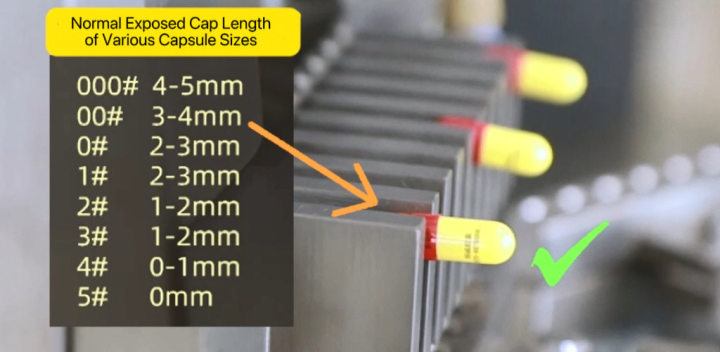

Before troubleshooting, it is important to know the normal exposed length of capsule caps exceeding the capsule feeding comb for different capsules with sizes (from capsule 000 to capsule 5). For example, a size 00 capsule should typically expose 3 to 4mm out of a comb. If the actual length deviates, adjustment is needed.

Loosen screws on the gelatin capsule feeding module and gently move it up and down manually.

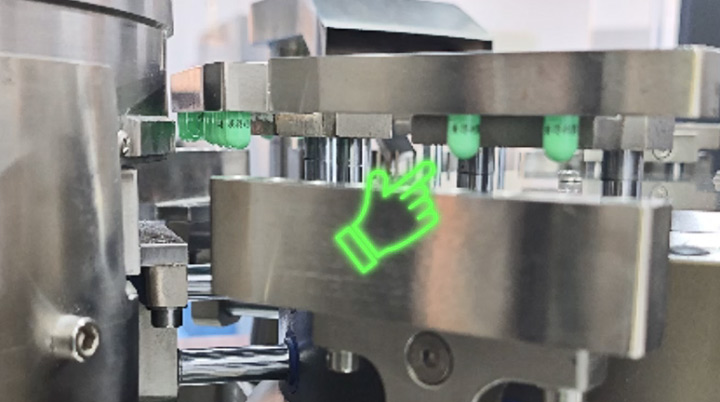

In another aspect, check if the small pressure wheel under the capsule feeding tube switch is correctly positioned. If capsules are missing, or only one capsule is dispensed per cycle as shown in the picture, it indicates the wheel is likely misaligned. Adjust it by turning the adjacent screw and moving the wheel vertically in 0.5–1 mm increments until capsules are fed smoothly into mold holes.

In terms of additional solutions, ensure feeding tubes and mold holes are clean and free from powder buildup or debris. Next, check for possible worn-out parts such as feeding combs. If problems persist, inspect the capsule specifications, since an incorrect capsule size or deformed capsules can also cause feeding issues.

Issue 3: Capsule Caps Fly Off during Capsule Separation

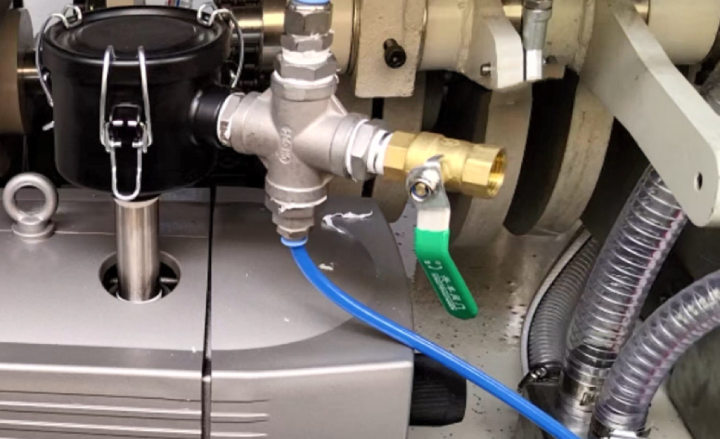

During the capsule separation process, the capsule body and capsule cap are successfully separated, but the capsule cap may detach from an upper mold hole. This issue occurs due to excessive vacuum pressure or misalignment.

To resolve this, first try to open the vacuum valve and appropriately reduce the vacuum level. Additionally, ensure proper alignment of upper and lower molds. Regular cleaning of mold cavities and using capsule caps with a consistent size also help maintain stable capsule separation.

If the problem continues, inspect vibration levels and clamping mechanisms of your powder capsule filling machine, as mechanical instability can contribute to capsule cap bouncing.

Issue 4: Capsules Fail to Be Separated

During separating capsules, you may encounter instances where individual hard capsules fail to be separated properly. The frequent cause is blockage in vacuum holes at the bottom of the capsule separation station. When these holes are clogged, suction force is lost, preventing capsule caps from being lifted and separated.

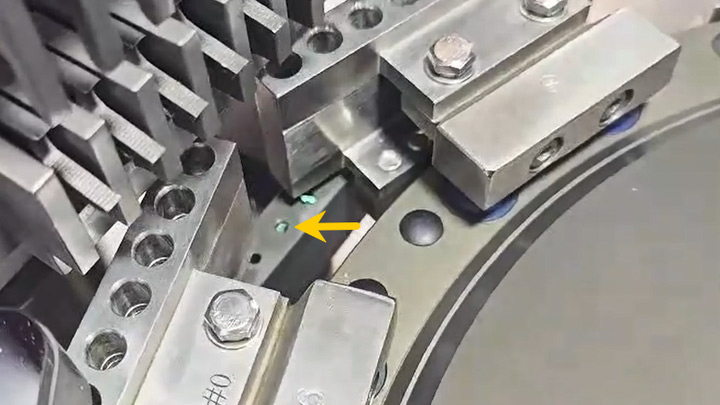

To address the blockage, first inspect vacuum holes for any powder or debris. Clear the blockage by using a vacuum cleaner or compressed air. Additionally, check components such as vacuum tubes and the vacuum valve, and ensure the tube is unobstructed and the valve opening is appropriately adjusted rather than overly wide.

Moreover, examine holes of upper and lower molds for material buildup. If dirt is found, carefully clean it by using suitable tools. At the capsule mold cleaning station, maximize the air blast valve to check whether strong airflow can remove residual powder from mold holes.

Another critical step is to inspect the concentricity of the upper and lower mold holes by using an alignment rod. Misalignment between hard capsule upper and lower mold holes physically hinders capsule separation.

Additionally, verifying that the vacuum pressure level is correctly set according to the capsule size and material properties. Don’t forget to train operators to perform routine checks and cleaning during production shifts in order to prevent powder or gelatin buildup.

Issue 5: Incomplete Capsule Locking

Another common issue in capsule filling is incomplete capsule locking, where capsules do not close firmly after capsule filling. This can lead to product loss, quality problems, or even malfunction of your pharmaceutical capsule filling machine.

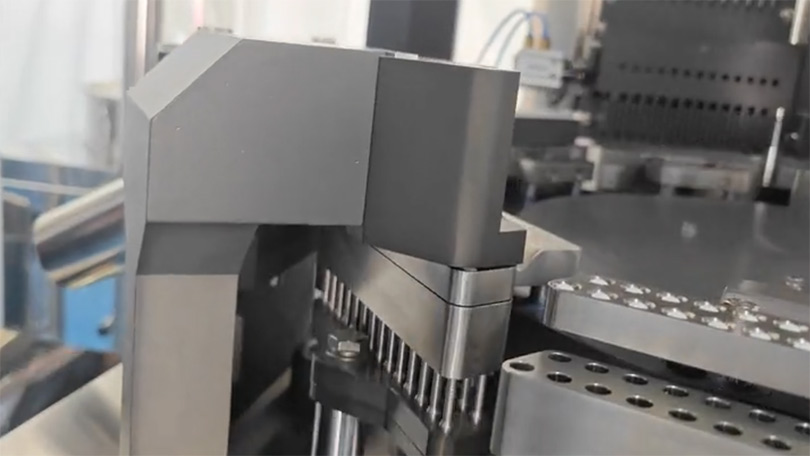

One effective solution is to adjust the connecting rod beneath capsule locking pins. Turn the adjustment screw slightly so that pins move up or down by about 1mm per adjustment. After each turn of adjustment, run your medical capsule filling machine briefly and check whether capsules are locked properly. Repeat this process until capsules are consistently locked.

Other potential ways to handle this issue is to check for any wear on capsule locking pins and replace them if necessary. Moreover, verify the speed of your 00 size capsule filling machine isn’t too high which reduces locking accuracy. Last but not least, clean capsule locking units to prevent residual powder buildup that affects capsule positioning.

Issue 6: Capsule Caps Are Sucked at Waste Rejection Station

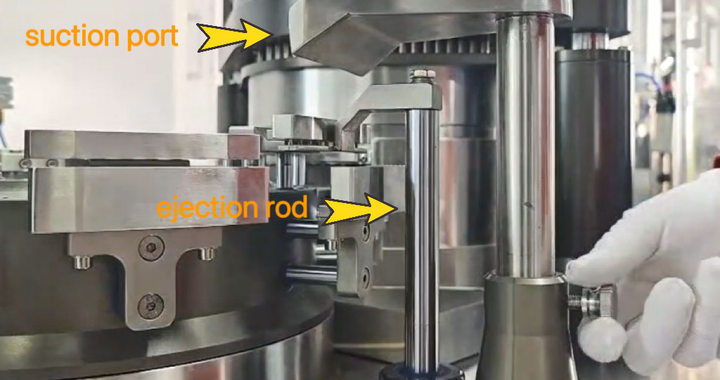

In the waste rejection process, a suction port is used to remove defective capsules. However, a typical issue is properly separated capsule caps are also accidentally drawn away by this suction port.

To address this, follow steps in jog mode:

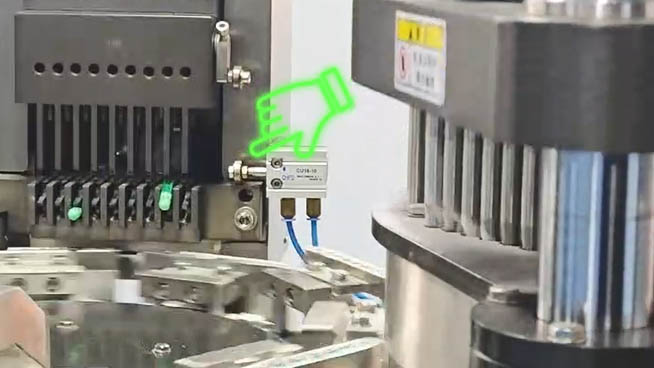

First, operate the high speed capsule filling machine in jog mode and allow defective capsule ejection pins to rise to their highest positions and pause. Then, loosen the screw at the base of the defective capsule suction port and adjust the height of the port.

After the adjustment, test run the automatic capsule filler filling machine. If capsule caps continue to be sucked away, gradually increase the waste capsule suction port’s height until the issue is resolved.

In addition to adjusting suction port height, check the suction pressure, since excessive suction force may draw away good capsule caps, and reducing vacuum intensity can help.

Issue 7: Scratching or Denting of Capsules During Capsule Locking

During the capsule locking stage on a pharmaceutical capsule filling machine, you may encounter an issue where capsules get scratched or dented. This not only affects the capsule appearance but also compromises capsule seal integrity and patient safety. The following are common causes and solutions.

●Misalignment of Upper and Lower Mold Holes: If these holes are not concentrically aligned, capsules may experience asymmetric pressure during capsule locking, leading to scratching or denting.

●Solution: Use an alignment rod to carefully correct the concentricity of mold holes.

●Bent Locking Pins: A bent locking pin can apply uneven force on capsules, causing surface damage.

●Solution: Inspect, straighten, or replace problematic locking pins if necessary.

●Residue Buildup on Locking Pin Tips: Residual powder accumulated on these tips can create unnecessary friction and imprint capsule bodies.

●Solution: Clean top surface of capsule sealing pins regularly.

●Excessive Upward Travel of Capsule Locking Pins: If a locking pin rises too high, it may apply excessive pressure on capsules, leading to capsule deformation.

●Solution: Adjust the height setting of locking pins to limit their upward movement.

●Worn-Out Upper or Lower Mold Holes: Over time, mold holes may wear out, resulting in imprecise guidance and misalignment during capsule sealing.

●Solution: Replace worn-out upper and lower molds.

●Excessive Capsule Locking Pressure: Over-tightening the locking mechanism or using excessive force can deform capsules rather than securing them gently.

●Solution: Calibrate the locking pressure settings of your medical capsule filling machine according to capsule specifications.

●Machine Vibration: External vibrations or an unsteady working platform may cause slight misalignment during the capsule locking process.

●Solution: Ensure your njp capsule filling machine is placed on a stable surface and check for loose components.

คำพูดสุดท้าย

While operating automatic capsule filling machines, you may encounter practical issues such as sudden machine halts or powder leakage from the filling mechanism. Based on hands-on experience, I have compiled detailed solutions for tackling typical challenges. Should you need more detailed guidance? Feel free to reach us for further support.