- Lar

- Máquina de enchimento de cápsulas

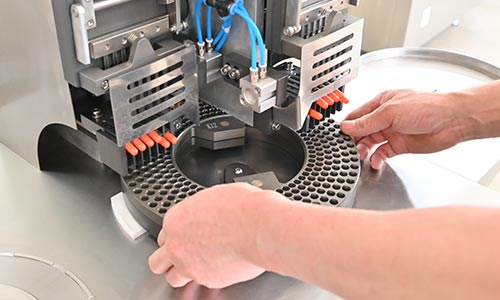

- Máquina de enchimento de cápsulas semiautomática

Máquina de enchimento de cápsulas semiautomática

A produção da máquina de enchimento de cápsulas semi-automática necessita da assistência de um operador para mover as placas de enchimento entre as diferentes secções do processo. É mais económica e fácil de utilizar.

Capable Capsule sizes:

|  |  |  |  |  |  |  | |

| Capsule Size | #000 | #00 | #0 | #1 | #2 | #3 | #4 | #5 |

| Locked Length | 26.14mm | 23.30mm | 21.7mm | 19.4mm | 18.0mm | 15.9mm | 14.3mm | 11.1mm |

| Capsule Volume | 1.37 ml | 0.91 ml | 0.68 ml | 0.5 ml | 0.37 ml | 0.3 ml | 0.21ml | 0.13ml |

(The filling amount may vary because of the powder difference)

How Semi-automatic Capsule Filling Machine works?

The Complete Range of Semi-automatic Capsule Filling Machines

Máquina de enchimento de cápsulas semiautomática

A máquina envasadora de cápsulas semi-automática pode encher pó, grânulos, pellets e líquidos em cápsulas duras, adequadas para cápsulas de tamanho ...

| Modelo | CGN-208 | CGNT-209 |

| Saída | 28,000pcs/h | 40,000pcs/h |

| Cápsula aplicável | 000#、00#、0#、1#、2#、3#、4#、5# | |

| Fonte de energia | 2,12 kW | 2,2kw |

| Poder | 380/220V 50Hz (personalizável) | |

| Peso líquido | 400 kg | 405 kg |

| Tamanho da embalagem | 1640*720*1700 mm | 1640*720*1700 mm |

Um investimento inteligente para a indústria farmacêutica

Fácil de utilizar

Cost-Friendly

Accurate

Safe to Operate

No Pollution

Nós cuidamos de você com um serviço completo

Garantia vitalícia

Entrega rápida em 7 dias

Serviço online 24 horas por dia, 7 dias por semana

Perguntas frequentes

- Lubrificar regularmente o excêntrico para o manter em bom estado.

- Desmontar e limpar a estação de enchimento para retirar o excesso de material, a fim de evitar entupimentos e ferrugem, após a conclusão da produção.

- Adicionar regularmente óleo lubrificante à bomba de vácuo e limpar o pó.

- Encher regularmente o depósito de água com água suficiente para cobrir metade do corpo do barril.

Semi-automatic Capsule Filling Machine Working Principle

A semi-automatic capsule filling machine separates empty capsules, fills them with the desired material, and closes them.

It involves following steps:

- Capsule separation

- Filling station setup

- Filling the hopperial

- Capsules alignment and orientation

- Dosage adjustment

- Filling the capsules

- Capsule Closing

- Ejecting the filled capsules

Automatic vs. Semi-automatic Capsule Filling Machine

Máquina automática de enchimento de cápsulas

Pros:

Automatic machines offer high-speed production capabilities, filling capsules quickly and efficiently, which is beneficial for large-scale manufacturing.

They require minimal manual intervention, reducing the need for extensive human labor and increasing productivity.

Automatic machines are designed for precise dosing, ensuring consistent and accurate filling of capsules.

They often come with additional features such as capsule sorting, automatic capsule orientation, and online inspection systems, enhancing overall operational efficiency.

Cons:

Automatic machines tend to have a higher upfront cost compared to semi-automatic machines, making them a significant investment.

Operating and maintaining automatic machines may require specialized training and technical expertise due to their complex nature.

These machines may have limitations when it comes to accommodating small-batch production or frequent product changes.

Automatic machines are generally larger and require more space in the manufacturing facility.

Máquina de enchimento de cápsulas semiautomática

Pros:

Semi-automatic machines are generally more cost-effective, making them a viable option for smaller manufacturers or startups with limited budgets.

They offer more flexibility in terms of production versatility, allowing easier adaptation for small-scale or diverse product lines.

Semi-automatic machines are relatively simpler to operate and require less technical expertise, enabling easier training and maintenance.

These machines are typically smaller, occupying less space in the production area.

Cons:

Semi-automatic machines require more manual handling, involving operators in the capsule filling process, which can be time-consuming and potentially introduce errors.

The filling speed is limited by manual handling, resulting in slower production rates compared to automatic machines.

There may be slight variations in filling accuracy or capsule quality due to the manual nature of the process.

Some semi-automatic machines may be less durable or prone to more frequent breakdowns compared to their automatic counterparts.