- Thuis

- Capsule vulmachine

- Machine voor het vullen van vloeibare capsules

Machine voor het vullen van vloeibare capsules

This liquid capsule machine is fully automatic to fill and seal the liquid and other materials into empty hard capsules.

It provides a highly active and insoluble pharmaceutical solution for packaging liquid materials for many large and small pharmaceutical companies and health care products manufacturers.

Capable Capsule sizes:

Liquid capsule filling machine is available in 8 kinds of standard capsule sizes.

|  |  |  |  | |

| Capsulegrootte | #00 | #0 | #1 | #2 | #3 |

| Locked Length | 23.30mm | 21.7mm | 19.4mm | 18.0mm | 15.9mm |

| Capsule Volume | 0.91 ml | 0.68 ml | 0.5 ml | 0.37 ml | 0.3 ml |

(The filling amount may vary because of the powder difference)

Hoe het werkt

Except for just simply injecting the liquid ingredient into a capsule, rich packing liquid capsule filling machine is equipped with working sections and technologies to ensure a smooth and efficient production process.

Capsule Rectification

Separating Caps & Bodies

Filling Liquid

Defective Capsules Ejection

Afdichten

Drogen

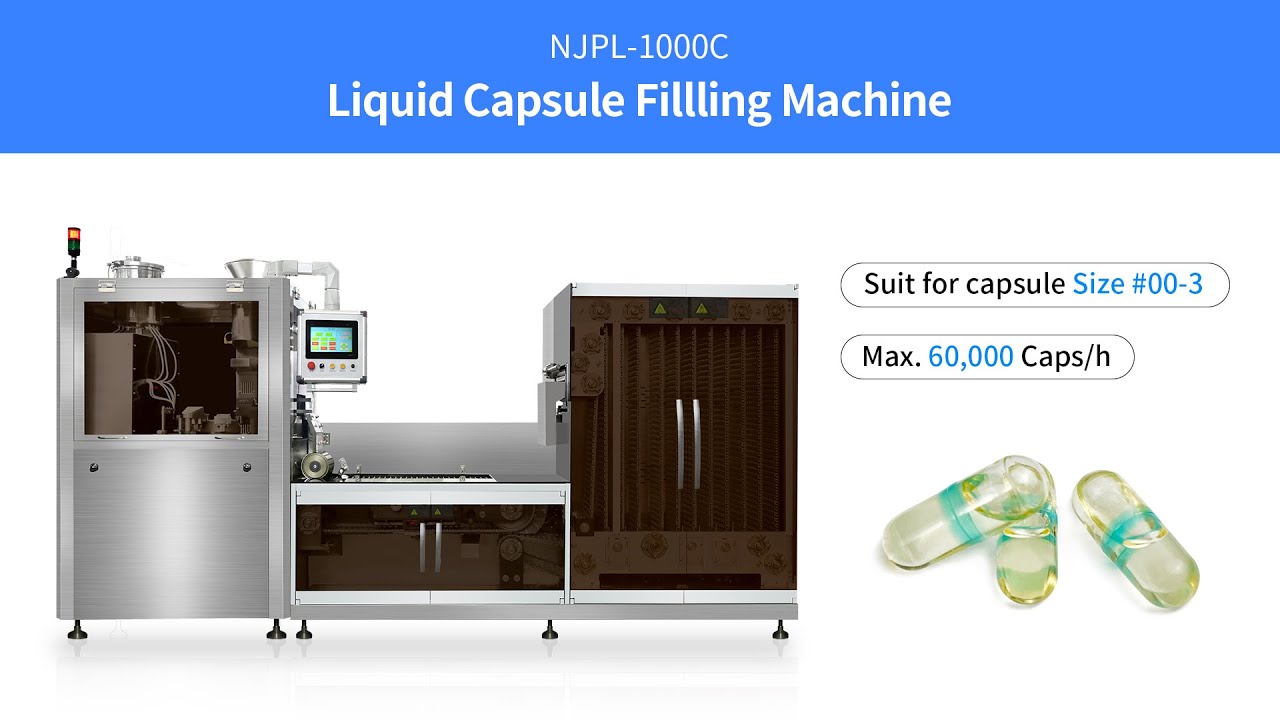

The Complete Range of Liquid Capsule Filling Machines

A wide variety of machine models with different capacities and budgets for you to choose from.

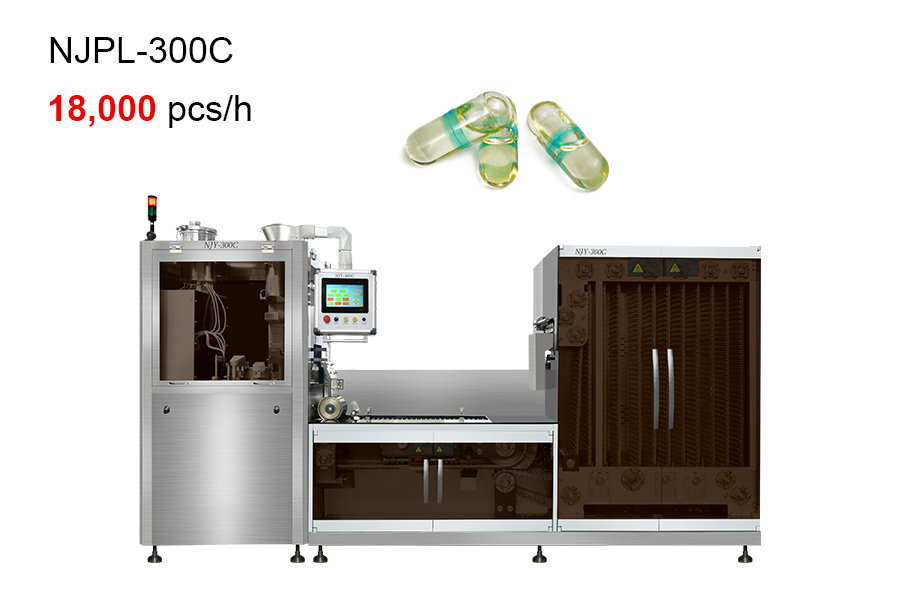

| Model | CGNL-300 | NJPL-100C | NJPL-300C | NJPL-600C |

| Uitvoer | 15000-28000pcs/h | 100 pcs/min | 300 pcs/min | 600 pcs/min |

| Capsule Sizes Compatibility | 00#、0#、1#、2#、3# | |||

| Totaal vermogen | 2,12 kW | 3.5KW | 5KW | 6KW |

| Stroom | 380/220V 50Hz (aanpasbaar) | |||

| Gewicht | 400KG | 500KG | 750KG | 900KG |

| Dimension (L*W*H) | 1300*800*1750mm | 700*800*1700mm | 860*960*1800mm | 960*1000*1900mm |

Not sure which machine is best for you? Our team can provide a proposal based on your needs and budget!

NJPL-330C Automatische Vloeibare Capsule Vulmachine

NJPL-330C Automatic Liquid Capsule Filling Machine fills and seals oils, suspensions, pastes, and viscous solutions into hard capsules (sizes ...

A Wise Investment for Pharma

Wij streven ernaar machines te produceren met superieure kwaliteit die voldoen aan de GMP-normen en die tegelijkertijd efficiënte en praktische functies bieden.

High accuracy

With Japan’s Yaskawa servo motor, the error of liquid injection is less than 2%. The problem of unevenness caused by the sticky material of is well solved by the ceramic pump.

No Leakage

Equipped with the corresponding sealing liquid according to the type of capsule used by the customer, the sealing is tight and no leakage.

Pollution-free

The rotary design to obtain a patent for utility model. SIL silicone sealing ring effectively prevents liquid into the internal turntable and dust overflow pollution.

Durable Material

All the parts that contact ingredients directly are made of Medical-grade stainless steel 316L, and the output device adopts seven lines with aero aluminum.

Wij staan voor u klaar met uitgebreide service

Wij staan u bij gedurende het gehele proces, van het kiezen van de juiste machine tot het goed onderhouden ervan gedurende uw hele leven.

Levenslange garantie

Om langdurig optimale prestaties te garanderen, bieden we gratis reparatie binnen 3 jaar en gratis reserveonderdelen binnen 1 jaar. Daarna beloven we levenslang gratis technisch advies.

Snelle levering binnen 7 dagen

95% van onze standaardmachines hebben we op voorraad. In dat geval kan de levering binnen 7 dagen plaatsvinden. Voor producten op maat geldt een levertijd van slechts 20 dagen.

24/7 online service

Onze deskundige klantexperts en technici richten zich op uw behoeften en lossen al uw problemen binnen 24 uur op.

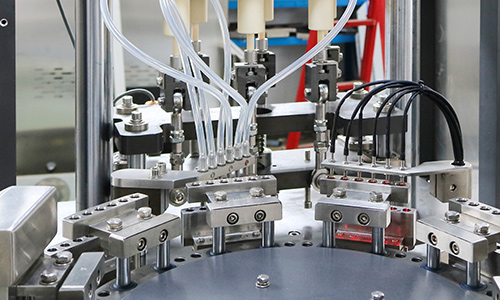

The Main Structure of Liquid Capule Machine

PLC Control System

The machine adopts the internationally famous human-machine interface PLC control system, and the PLC real-time monitoring of the whole operation process is realized, and the automatic capsule and material shortage alarms are realized.

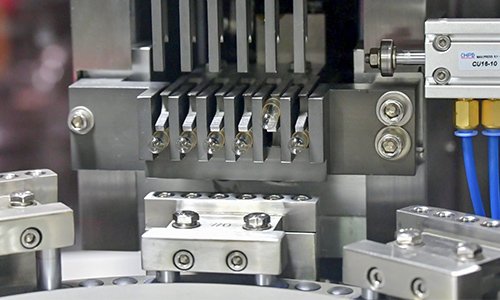

Empty Capsule Filling System

The specially configured capsule feeding machine has a vacuum positioning and separation mechanism to ensure that the capsule loading rate is over 99.5%.

Liquid Injecting System

The accuracy of dosage adopts the liquid adding system of servo motor and high-precision ceramic pump to ensure that the difference of capsule material filling quantity is controlled less than 2%.

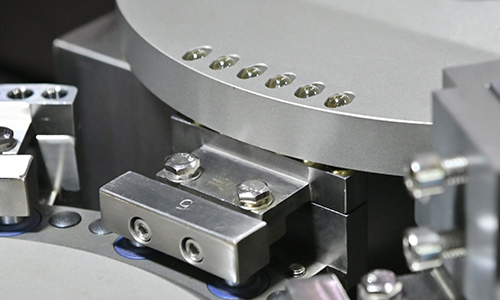

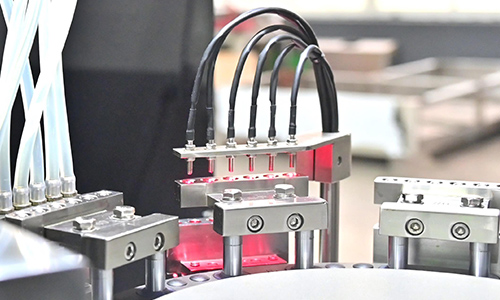

Sealing System

The sealing mechanism of the liquid capsule product adopts a servo motor to control the lifting function, which realizes the up and down jog and the fine adjustment of the rubber wheel, and realizes the best effect of the liquid sealing layer.

Heat Preservation System

The sealing structure is designed in the liquid sealing tank, and the heating and heat preservation system is equipped to ensure the viscosity of the capsule glue.

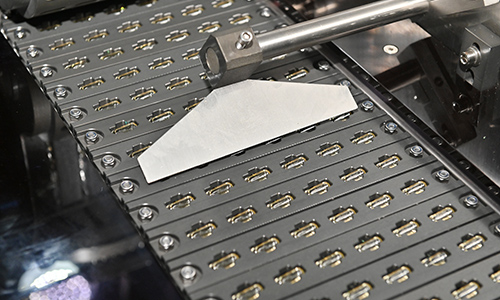

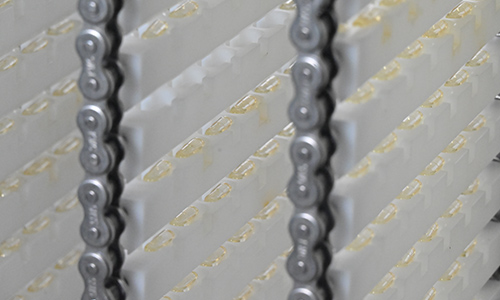

Drying System

The drying mode of the liquid hard capsule finished product adopts a vertical suspension and free rotation structure, which reduces the drying time of the capsule and the installation, disassembly and cleaning time of the capsule filling machine by 50%.

Veelgestelde vragen

Here are some main specifics that you need to consider, such as capsule size and type, applicable ingredient, production capacity, machine size, and warranty. Due to the cost of the machine is a huge budget, a complete and long aftersale service can help a lot for a long run business.

CE: Conformiteit van de Europese Unie GMP: Goede Productiepraktijken ISO: Internationale Organisatie voor Standaardisatie FDA: Voedsel- en Warenautoriteit

- Lubricate cam regularly to keep it in good condition.

- Disassemble and clean the filling station to clear the excess material to prevent blockage and rust, after the production is finished.

- Add lubricating oil to the vacuum pump regularly and clean up the dust.

- Fill enough water over half of the barrel body in water tank regularly.

How to Fill Capsules With Liquid?

Get to know how liquid capsule filling machine works step by step.

1. Capsule Rectification

The liquid capsule filling machine aligns and positions the capsules in the correct orientation for filling. This ensures that the capsules are ready to receive the liquid formulation.

2. Separating Capsule

The machine separates the cap and body components of the capsules. This allows for individual handling of the caps and bodies during the filling process.

3. Filling Liquid

The machine dispenses the liquid formulation into the capsule bodies. The filling parameters, such as volume and speed, are adjustable to ensure accurate and consistent filling.

4. Defects Ejection

The machine inspects the filled capsules for any defects or abnormalities. If a capsule is found to be defective, it is automatically ejected from the production line.

5. Sealing

The machine places the capsule caps onto the filled bodies. The sealing process ensures that the capsules are securely closed and sealed.

6. Drying

This step removes excess moisture or liquid from the capsules. This step removes excess moisture or liquid from the capsules.