สายการบรรจุกล่องแบบพุพอง

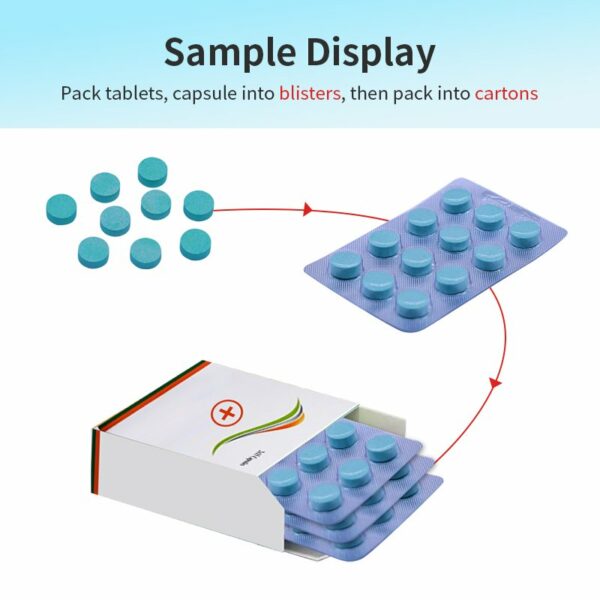

Blister cartoning packing line automates the end-to-end process of creating blister packs and loading them into cartons. First, pvc are thermoformed into blister cavities. Products (tablets, capsules) are precisely loaded into these blisters via customized feeders. Next, the blister is sealed with aluminum foil using heat and pressure to ensure tamper-proof protection.

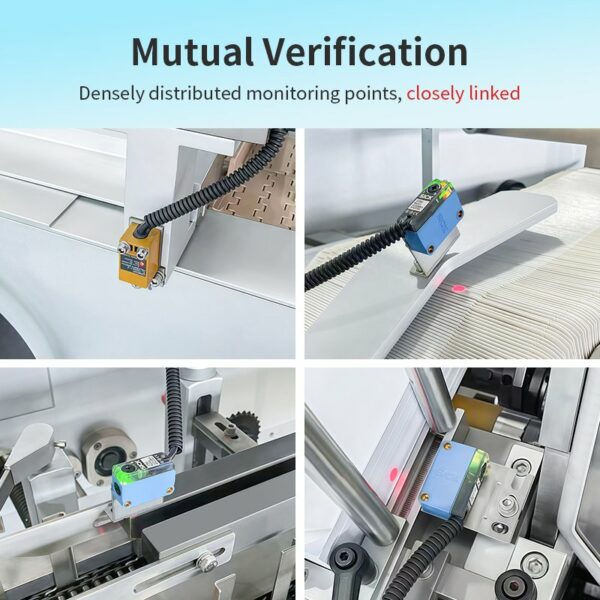

Integrated vision systems inspect for defects like empty blisters, misaligned seals, or missing leaflets. Approved blisters are then transferred to a cartoning module, where pre-folded boxes are erected, filled with blisters and inserts (instructions), and sealed via tuck-in flaps or glue. Rejection mechanisms remove faulty units, while finished cartons exit for labeling or secondary packaging.

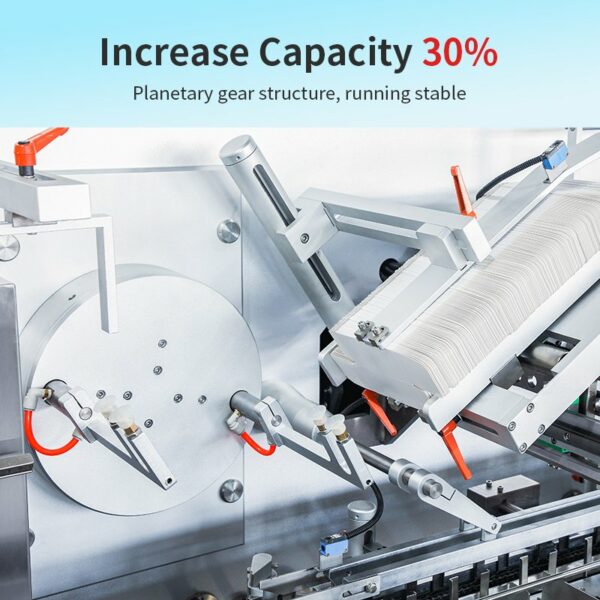

The line combines blister forming, sealing, inspection, and cartoning into a seamless, cGMP-compliant workflow, ensuring high-speed production, minimal waste, and adaptability to diverse product sizes. Ideal for pharmaceuticals, food, and consumer goods, it prioritizes precision, hygiene, and scalability.

ข้อมูลจำเพาะ:

สูงสุด 130 กล่อง/นาที

ใช้ได้กับยาเม็ด แคปซูล และยาเม็ด ฯลฯ

รับประกัน 3 ปี อะไหล่ฟรี 1 ปี