- Дом

- Машина для наполнения капсул

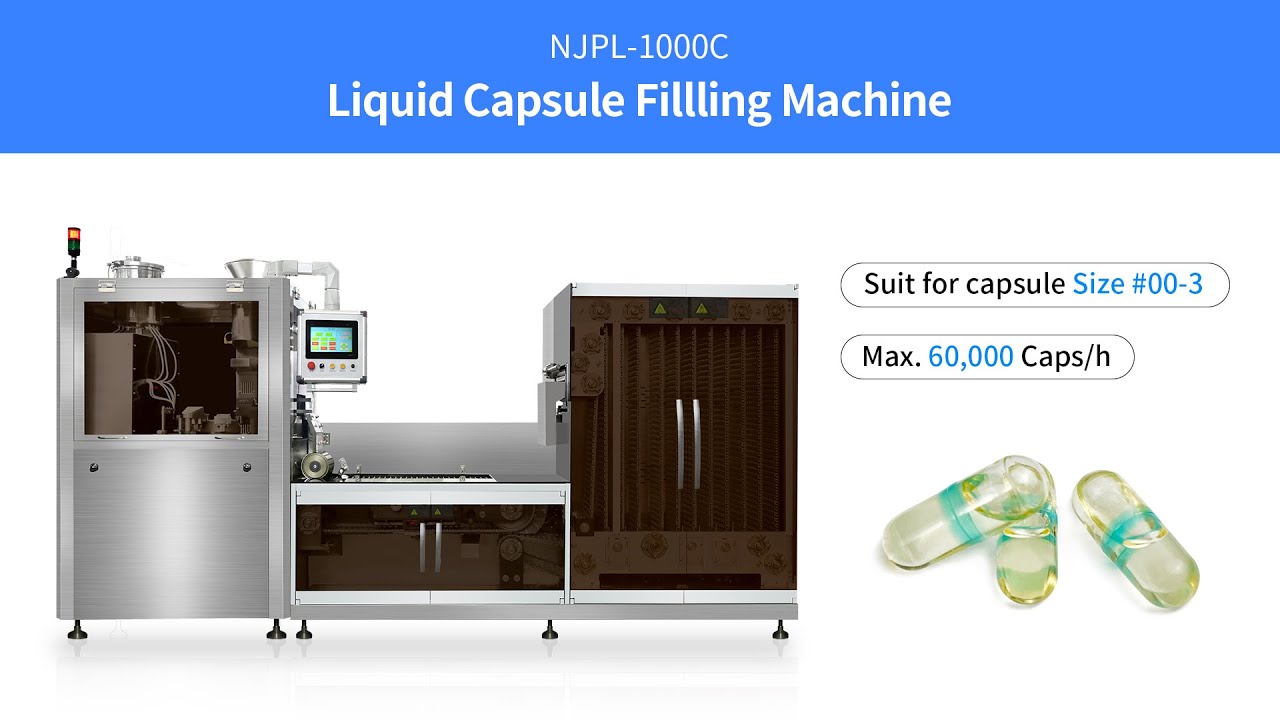

- Машина для наполнения капсул жидкостью

Машина для наполнения капсул жидкостью

Эта машина для жидких капсул полностью автоматизирована и осуществляет заполнение и герметизацию пустых твердых капсул жидкими и другими материалами.

Он обеспечивает высокоактивное и нерастворимое фармацевтическое решение для упаковки жидких материалов для многих крупных и мелких фармацевтических компаний и производителей продукции медицинского назначения.

Возможные размеры капсул:

Машина для наполнения капсул жидкими веществами доступна в 8 видах стандартных размеров капсул.

|  |  |  |  | |

| Размер капсулы | #00 | #0 | #1 | #2 | #3 |

| Заблокированная длина | 23,30 мм | 21,7 мм | 19,4 мм | 18,0 мм | 15,9 мм |

| Объем капсулы | 0,91 мл | 0,68 мл | 0,5 мл | 0,37 мл | 0,3 мл |

(Объем наполнения может варьироваться из-за разницы в составе порошка)

Как это работает

Помимо простого впрыскивания жидкого ингредиента в капсулу, машина для наполнения капсул жидкостью Rich Pack оснащена рабочими секциями и технологиями, обеспечивающими плавный и эффективный процесс производства.

Ректификационная капсула

Разделение крышек и корпусов

Заполняющая жидкость

Выброс дефектных капсул

Уплотнение

Сушка

Полный ассортимент машин для наполнения капсул жидкими веществами

Широкий выбор моделей машин с различной производительностью и бюджетом на ваш выбор.

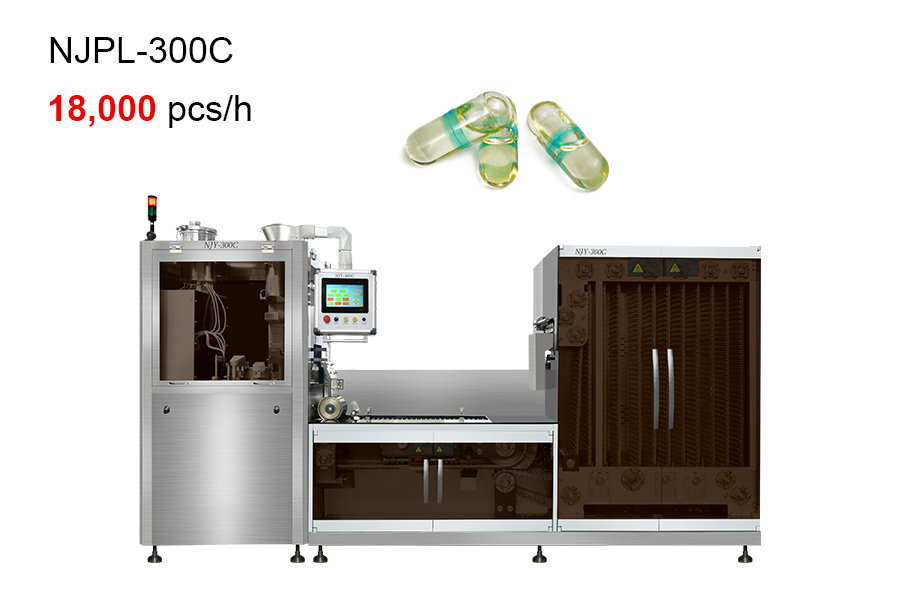

| Модель | CGNL-300 | NJPL-100C | NJPL-300C | NJPL-600C |

| Выход | 15000-28000шт/ч | 100 шт/мин | 300 шт/мин | 600 шт/мин |

| Совместимость размеров капсул | 00#、0#、1#、2#、3# | |||

| Общая мощность | 2.12кВт | 3,5 кВт | 5КВт | 6КВт |

| Власть | 380/220 В 50 Гц (настраивается) | |||

| Масса | 400КГ | 500КГ | 750КГ | 900КГ |

| Размеры (Д*Ш*В) | 1300*800*1750мм | 700*800*1700мм | 860*960*1800мм | 960*1000*1900мм |

Не знаете, какая машина подойдет вам лучше всего? Наша команда может предоставить предложение, основанное на ваших потребностях и бюджете!

Автоматическая машина для заполнения капсул жидкостью NJPL-330C

Автоматическая машина для наполнения капсул жидкостями NJPL-330C заполняет и запечатывает масла, суспензии, пасты и вязкие растворы в твердые капсулы (размеры ...

Мудрая инвестиция в фармацевтику

Мы стремимся производить машины высочайшего качества, соответствующие стандартам GMP, обладающие при этом эффективными и полезными характеристиками.

Высокая точность

Благодаря японскому серводвигателю Yaskawa погрешность впрыска жидкости составляет менее 2%. Проблема неравномерности, вызванная липким материалом, успешно решена благодаря керамическому насосу.

Нет утечки

Заполненная соответствующей герметизирующей жидкостью в соответствии с типом капсулы, используемой заказчиком, капсула герметична и не имеет утечек.

Без загрязнения

Получен патент на полезную модель роторной конструкции. Уплотнительное кольцо из силикона SIL эффективно предотвращает попадание жидкости во внутреннюю часть поворотного стола и загрязнение пылью.

Прочный материал

Все детали, которые напрямую контактируют с ингредиентами, изготовлены из медицинской нержавеющей стали 316L, а выходное устройство оснащено семью линиями из аэродинамического алюминия.

Мы поддержим вас, предоставив комплексное обслуживание

Мы будем рядом с вами на протяжении всего процесса, от выбора подходящей машины до надлежащего ухода за ней на протяжении всей ее жизни.

Пожизненная гарантия

Чтобы обеспечить превосходную производительность в течение длительного времени, мы предлагаем бесплатный ремонт в течение 3 лет и бесплатные запасные части в течение 1 года. После этого мы обещаем бесплатную техническую консультацию на всю жизнь.

Быстрая доставка за 7 дней

95% наших стандартных машин есть в наличии. В таком случае доставка может быть осуществлена в течение 7 дней. Что касается глубоко персонализированных продуктов, то доставка занимает всего 20 дней.

Круглосуточное онлайн-обслуживание

Наши опытные специалисты и инженеры выявят ваши потребности и решат все ваши проблемы в течение 24 часов.

Основная конструкция машины для производства жидких капсул

Система управления ПЛК

Машина оснащена всемирно известной системой управления с человеко-машинным интерфейсом на основе ПЛК, реализуется мониторинг всего рабочего процесса в режиме реального времени с помощью ПЛК, а также реализованы автоматические сигналы тревоги о нехватке капсул и материала.

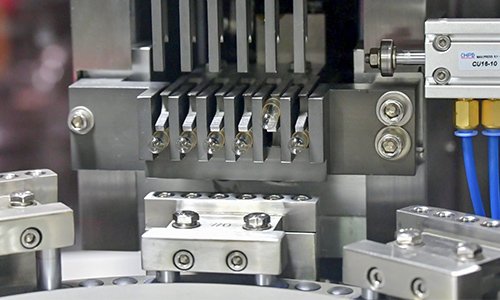

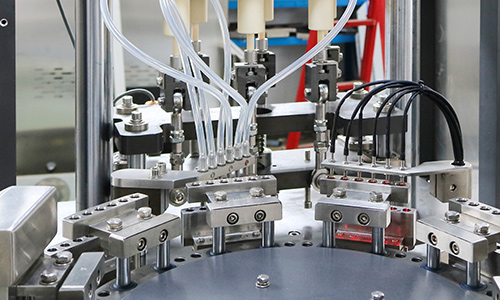

Система наполнения пустых капсул

Специально сконфигурированная машина для подачи капсул оснащена вакуумным механизмом позиционирования и разделения, обеспечивающим скорость загрузки капсул более 99,5%.

Система впрыска жидкости

Точность дозировки достигается за счет использования системы добавления жидкости с серводвигателем и высокоточным керамическим насосом, что позволяет контролировать разницу в количестве наполняемого материала капсулы менее чем на 2%.

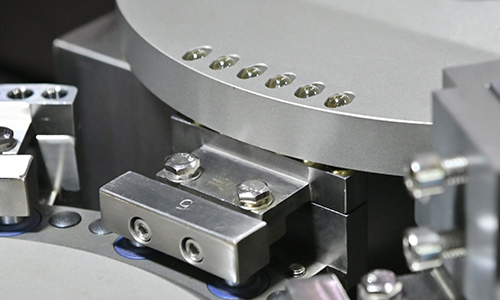

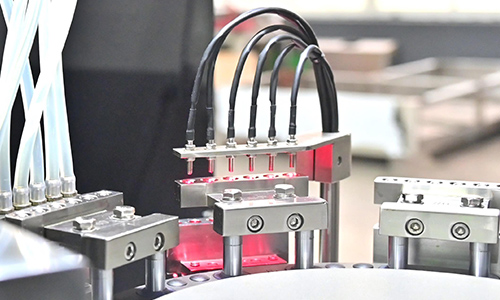

Система герметизации

Механизм герметизации продукта в виде жидкой капсулы использует серводвигатель для управления функцией подъема, который осуществляет толчковое движение вверх и вниз и точную регулировку резинового колеса, а также реализует наилучший эффект слоя жидкой герметизации.

Система сохранения тепла

Уплотнительная конструкция спроектирована в резервуаре для жидкого герметика, а система подогрева и сохранения тепла оснащена для обеспечения вязкости капсульного клея.

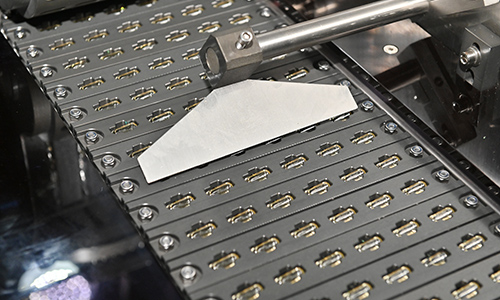

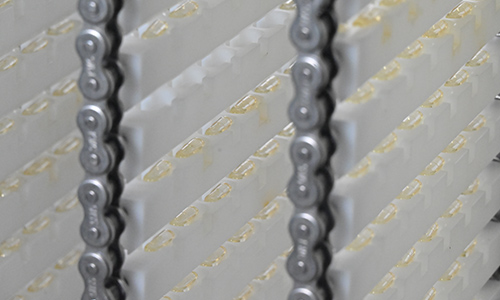

Система сушки

Режим сушки готового продукта в виде жидких твердых капсул использует вертикальную подвесную и свободно вращающуюся структуру, что сокращает время сушки капсул, а также время установки, разборки и очистки машины для наполнения капсул 50%.

Часто задаваемые вопросы

Вот некоторые основные характеристики, которые следует учитывать, такие как размер и тип капсул, используемый ингредиент, производительность, размер машины и гарантия. Поскольку стоимость машины довольно высока, полное и длительное послепродажное обслуживание может существенно помочь бизнесу в долгосрочной перспективе.

CE: Conformite Europeenne GMP: Надлежащая производственная практика ISO: Международная организация по стандартизации FDA: Управление по контролю за продуктами питания и лекарственными средствами

- Регулярно смазывайте кулачок, чтобы поддерживать его в хорошем состоянии.

- После завершения производства разберите и очистите заправочную станцию, чтобы удалить излишки материала и предотвратить засорение и ржавчину.

- Регулярно добавляйте смазочное масло в вакуумный насос и очищайте его от пыли.

- Регулярно наливайте в резервуар для воды достаточное количество воды, превышающее половину корпуса бочки.

Как наполнить капсулы жидкостью?

Изучите шаг за шагом, как работает машина для наполнения капсул жидкостью.

1. Капсульная ректификация

Машина для наполнения капсул выравнивает и располагает капсулы в правильном положении для наполнения. Это гарантирует их готовность к заполнению жидким составом.

2. Разделительная капсула

Машина разделяет крышки и корпуса капсул. Это позволяет обрабатывать крышки и корпуса по отдельности в процессе наполнения.

3. Заливка жидкости

Машина дозирует жидкую форму в корпуса капсул. Параметры наполнения, такие как объём и скорость, регулируются для обеспечения точного и равномерного наполнения.

4. Удаление дефектов

Машина проверяет заполненные капсулы на наличие дефектов и отклонений. Если капсула оказывается бракованной, она автоматически выбрасывается с производственной линии.

5. Герметизация

Машина устанавливает крышки капсул на заполненные корпуса. Процесс запечатывания обеспечивает надёжное закрытие и герметичность капсул.

6. Сушка

На этом этапе из капсул удаляется лишняя влага или жидкость. На этом этапе из капсул удаляется лишняя влага или жидкость.