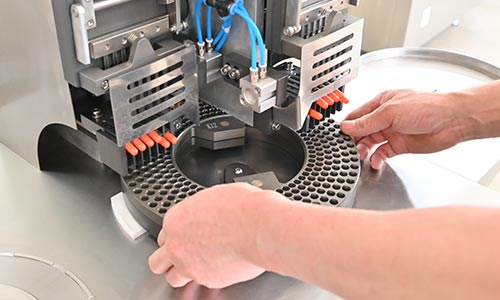

半自動カプセル充填機

The production of semi-automatic capsule filling machine needs assistance from an operator by moving the filling plates between the different sections in the process. It‘s more cost-friendly and user-friendly.

対応カプセルサイズ:

|  |  |  |  |  |  |  | |

| カプセルサイズ | #000 | #00 | #0 | #1 | #2 | #3 | #4 | #5 |

| ロックされた長さ | 26.14mm | 23.30mm | 21.7mm | 19.4mm | 18.0mm | 15.9mm | 14.3mm | 11.1mm |

| カプセル容量 | 1.37ミリリットル | 0.91ミリリットル | 0.68ミリリットル | 0.5ml | 0.37ミリリットル | 0.3ml | 0.21ml | 0.13ml |

(粉の違いにより充填量が異なる場合があります)

半自動カプセル充填機はどのように機能しますか?

The Complete Range of Semi-automatic Capsule Filling Machines

半自動カプセル充填機

Semi automatic capsule filler machine can fill powder, granule, pellet and liquid into hard capsule, suitable for capsule size ...

| モデル | CGN-208 | CGNT-209 |

| 出力 | 28,000pcs/h | 40,000pcs/h |

| Applicable Capsule | 000#、00#、0#、1#、2#、3#、4#、5# | |

| 電源 | 2.12kW | 2.2kw |

| 力 | 380/220V 50Hz(カスタマイズ可能) | |

| Net weight | 400kg | 405kg |

| Packing size | 1640×720×1700mm | 1640×720×1700mm |

製薬業界にとって賢明な投資

Easy to Use

Cost-Friendly

Accurate

Safe to Operate

No Pollution

包括的なサービスでお客様をサポートします

生涯保証

7日以内に迅速に配送

24時間365日オンラインサービス

よくある質問

- カムを良好な状態に保つために定期的に潤滑してください。

- 生産が終了したら、詰まりや錆を防ぐために充填ステーションを分解して清掃し、余分な材料を取り除きます。

- 定期的に真空ポンプに潤滑油を補充し、ほこりを取り除いてください。

- 定期的に水タンクに樽本体の半分以上まで十分な水を入れてください。

Semi-automatic Capsule Filling Machine Working Principle

A semi-automatic capsule filling machine separates empty capsules, fills them with the desired material, and closes them.

It involves following steps:

- Capsule separation

- Filling station setup

- Filling the hopperial

- Capsules alignment and orientation

- Dosage adjustment

- Filling the capsules

- カプセルの閉鎖

- Ejecting the filled capsules

Automatic vs. Semi-automatic Capsule Filling Machine

自動カプセル充填機

長所だ:

Automatic machines offer high-speed production capabilities, filling capsules quickly and efficiently, which is beneficial for large-scale manufacturing.

They require minimal manual intervention, reducing the need for extensive human labor and increasing productivity.

Automatic machines are designed for precise dosing, ensuring consistent and accurate filling of capsules.

They often come with additional features such as capsule sorting, automatic capsule orientation, and online inspection systems, enhancing overall operational efficiency.

短所だ:

Automatic machines tend to have a higher upfront cost compared to semi-automatic machines, making them a significant investment.

Operating and maintaining automatic machines may require specialized training and technical expertise due to their complex nature.

These machines may have limitations when it comes to accommodating small-batch production or frequent product changes.

Automatic machines are generally larger and require more space in the manufacturing facility.

半自動カプセル充填機

長所だ:

Semi-automatic machines are generally more cost-effective, making them a viable option for smaller manufacturers or startups with limited budgets.

They offer more flexibility in terms of production versatility, allowing easier adaptation for small-scale or diverse product lines.

Semi-automatic machines are relatively simpler to operate and require less technical expertise, enabling easier training and maintenance.

These machines are typically smaller, occupying less space in the production area.

短所だ:

Semi-automatic machines require more manual handling, involving operators in the capsule filling process, which can be time-consuming and potentially introduce errors.

The filling speed is limited by manual handling, resulting in slower production rates compared to automatic machines.

There may be slight variations in filling accuracy or capsule quality due to the manual nature of the process.

Some semi-automatic machines may be less durable or prone to more frequent breakdowns compared to their automatic counterparts.