液体カプセル充填機

この液体カプセルマシンは、空のハードカプセルに液体やその他の材料を充填し、密封する全自動です。.

多くの大小の製薬会社やヘルスケア製品メーカーに、液体原料を包装するための高活性で不溶性の医薬品ソリューションを提供している。.

対応カプセルサイズ:

液体カプセル充填機は、8種類の標準カプセルサイズで利用可能です。.

|  |  |  |  | |

| カプセルサイズ | #00 | #0 | #1 | #2 | #3 |

| ロックされた長さ | 23.30mm | 21.7mm | 19.4mm | 18.0mm | 15.9mm |

| カプセル容量 | 0.91ミリリットル | 0.68ミリリットル | 0.5ml | 0.37ミリリットル | 0.3ml |

(粉の違いにより充填量が異なる場合があります)

仕組み

単に液体成分をカプセルに注入するだけでなく、豊富なパッキング液体カプセル充填機は、円滑かつ効率的な生産プロセスを確保するための作業部および技術が装備されています。.

カプセル整流

キャップとボディの分離

充填液

カプセル排出不良

シーリング

乾燥

液体カプセル充填機の完全な範囲

さまざまな容量と予算に応じた、さまざまなマシン モデルからお選びいただけます。

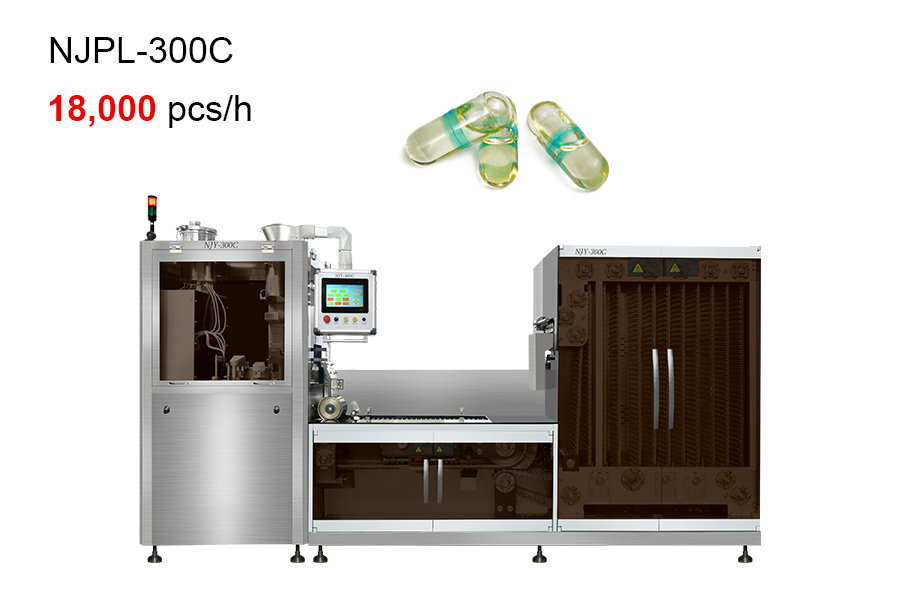

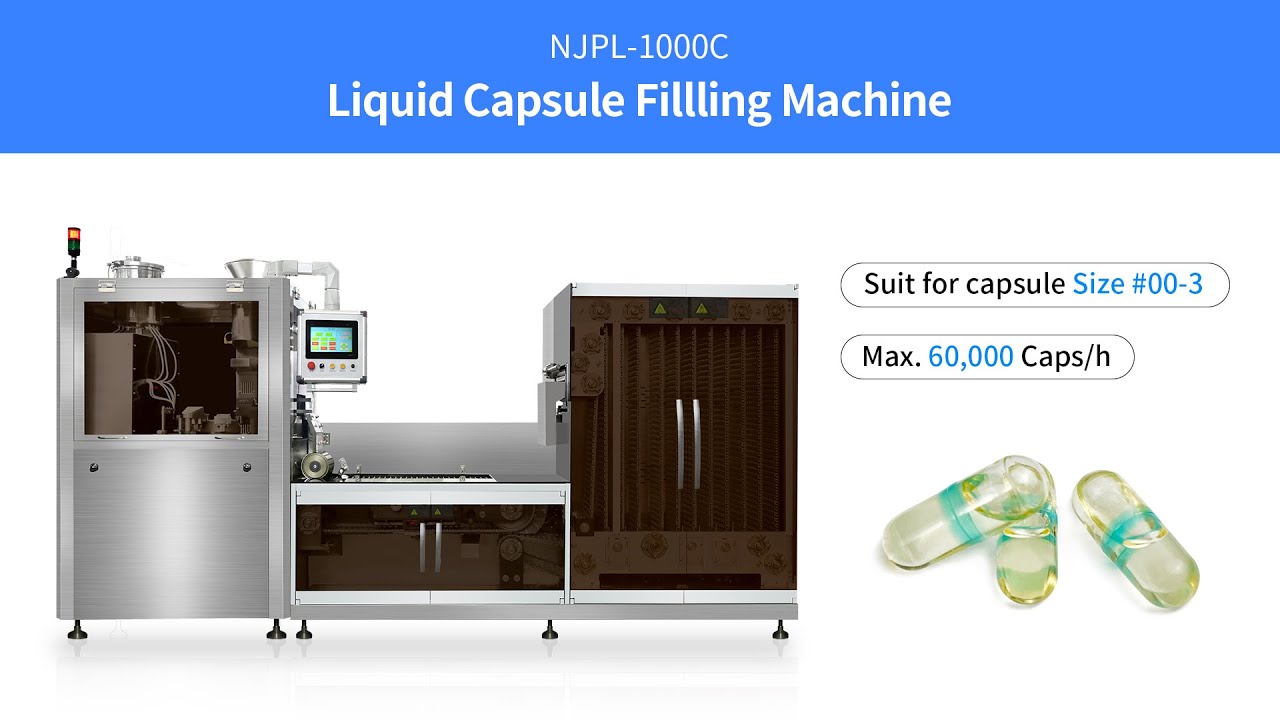

| モデル | CGNL-300 | NJPL-100C | NJPL-300C | NJPL-600C |

| 出力 | 15000-28000pcs/h | 100個/分 | 300個/分 | 600個/分 |

| カプセルサイズの互換性 | 00#、0#、1#、2#、3# | |||

| 総電力 | 2.12kW | 3.5KW | 5kW | 6KW |

| 力 | 380/220V 50Hz(カスタマイズ可能) | |||

| 重さ | 400KG | 500KG | 750KG | 900KG |

| 寸法(L*W*H) | 1300*800*1750mm | 700*800*1700mm | 860*960*1800mm | 960*1000*1900mm |

どのマシンが最適か分からないですか?当社のチームがお客様のニーズと予算に基づいたご提案をさせていただきます。

製薬業界にとって賢明な投資

当社は、効率的で実用的な機能を備えながら、GMP 基準を満たす優れた品質の機械を製造することに尽力しています。

高精度

日本製安川サーボモーターを使用し、液体噴射の誤差は2%以下。セラミックポンプを採用することで、粘着物による液ムラの問題を解決しました。.

漏れなし

顧客の使用するカプセルのタイプに応じて対応するシール液を装備し、シールはタイトで漏れがない。.

無公害

実用新案の特許を取得した回転設計。SILシリコンシーリングリングは、効果的に内部ターンテーブルへの液体やほこりのオーバーフロー汚染を防ぐことができます。.

耐久性のある素材

原料に直接触れる部分はすべて医療用ステンレス316L製で、出力装置はエアロアルミ製の7本ラインを採用している。.

包括的なサービスでお客様をサポートします

適切なマシンの選択から、生涯にわたるメンテナンスまで、プロセス全体を通してお客様をサポートします。

生涯保証

優れたパフォーマンスを長期間保証するため、3年間は無料修理、1年間は無料スペアパーツをご提供いたします。その後は、生涯にわたる無料技術相談をお約束いたします。

7日以内に迅速に配送

標準機95%は在庫がございますので、7日以内にお届け可能です。また、詳細なカスタマイズ製品につきましては、20日以内でお届けいたします。

24時間365日オンラインサービス

知識豊富なカスタマー エキスパートとエンジニアがお客様のニーズに応え、24 時間以内にすべての問題を解決します。

液体カプセルの主な構造

PLC制御システム

この機械は国際的に有名なヒューマン・マシン・インターフェースのPLC制御システムを採用し、全操業プロセスのPLCリアルタイム監視が実現され、自動カプセルと材料不足アラームが実現されます。.

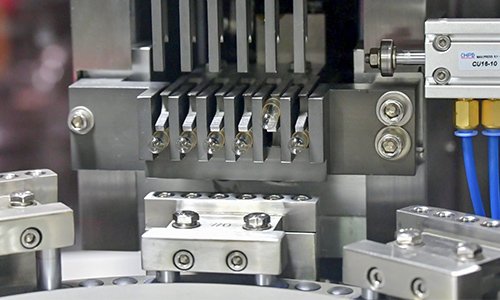

空カプセル充填システム

特別に構成されたカプセル供給機は、真空位置決めと分離機構を備え、カプセル充填率が99.5%以上であることを保証する。.

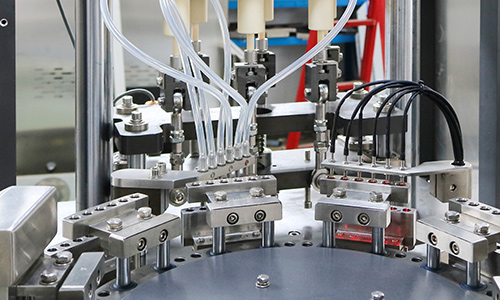

液体注入システム

投与量の精度はサーボモーターと高精度セラミックポンプの液体添加システムを採用し、カプセル材料の充填量の差が2%以下に制御されることを保証します。.

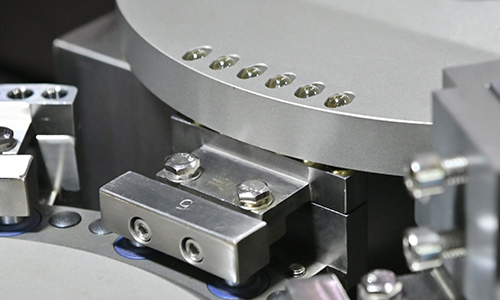

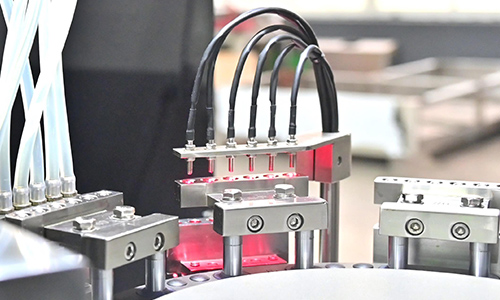

シーリング・システム

液体カプセル製品の密封機構はサーボモーターを採用し、昇降機能を制御し、ゴム車輪の上下ジョグと微調整を実現し、液体密封層の最高の効果を実現する。.

保温システム

密封構造は液体密封タンクで設計され、加熱保温システムはカプセル接着剤の粘度を確保するために装備されています。.

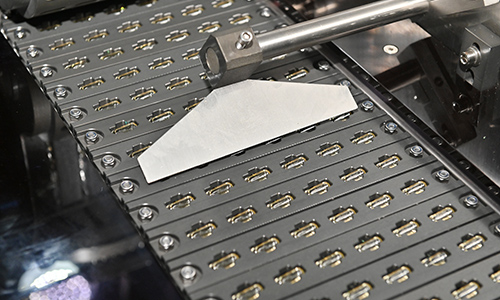

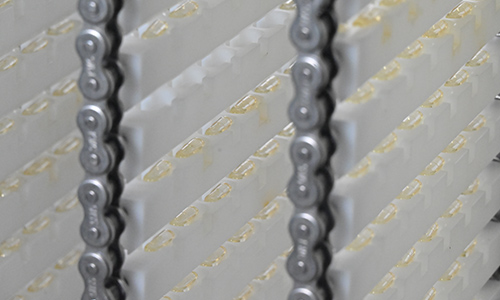

乾燥システム

液体ハードカプセル完成品の乾燥モードは、垂直懸垂と自由回転構造を採用し、カプセルの乾燥時間を短縮し、50%カプセル充填機の設置、分解、清掃時間を短縮します。.

よくある質問

カプセルのサイズと種類、適用可能な成分、生産能力、機械のサイズ、保証など、考慮すべき主な項目をいくつかご紹介します。機械のコストは巨額であるため、長期にわたるアフターサービスは、長期的なビジネス運営に大きく貢献します。

CE: 欧州規格 GMP: 適正製造規範 ISO: 国際標準化機構 FDA: 食品医薬品局

- カムを良好な状態に保つために定期的に潤滑してください。

- 生産が終了したら、詰まりや錆を防ぐために充填ステーションを分解して清掃し、余分な材料を取り除きます。

- 定期的に真空ポンプに潤滑油を補充し、ほこりを取り除いてください。

- 定期的に水タンクに樽本体の半分以上まで十分な水を入れてください。

カプセルを液体で満たすには?

液体カプセル充填機のステップバイステップの仕組みを知る。.

1.カプセル整流

液体カプセル充填機は、充填のためにカプセルを正しい方向に整列させ、位置決めします。これにより、カプセルは液体製剤を受け取る準備が整います。.

2.分離カプセル

この機械はカプセルのキャップと胴体を分離する。これにより、充填工程でキャップと本体を個別に取り扱うことができる。.

3.充填液

機械は液体製剤をカプセル本体に分注します。充填量や速度などの充填パラメーターは調整可能で、正確で安定した充填を実現します。.

4.欠陥排出

機械は充填されたカプセルに欠陥や異常がないか検査する。もしカプセルに欠陥が見つかれば、自動的に生産ラインから排出される。.

5.シーリング

機械は充填された本体にカプセルのキャップを被せる。シール工程により、カプセルは確実に閉じられ、密封される。.

6.乾燥

カプセルから余分な水分や液体を取り除く。このステップでは、カプセルから余分な水分や液体を取り除きます。.