- Rumah

- Mesin Pengisi Kapsul

- Mesin Pengisian Kapsul Cair

Mesin Pengisian Kapsul Cair

This liquid capsule machine is fully automatic to fill and seal the liquid and other materials into empty hard capsules.

It provides a highly active and insoluble pharmaceutical solution for packaging liquid materials for many large and small pharmaceutical companies and health care products manufacturers.

Ukuran Kapsul yang Mampu:

Liquid capsule filling machine is available in 8 kinds of standard capsule sizes.

|  |  |  |  | |

| Ukuran Kapsul | #00 | #0 | #1 | #2 | #3 |

| Panjang Terkunci | 23,30 mm | 21,7 mm | 19,4 mm | 18,0 mm2 | 15,9 mm |

| Volume Kapsul | 0,91 ml-an | 0,68 ml-an | 0,5 ml | 0,37 ml-an | 0,3 ml |

(Jumlah isi dapat bervariasi karena perbedaan bubuk)

Cara Kerjanya

Except for just simply injecting the liquid ingredient into a capsule, rich packing liquid capsule filling machine is equipped with working sections and technologies to ensure a smooth and efficient production process.

Capsule Rectification

Separating Caps & Bodies

Filling Liquid

Defective Capsules Ejection

Penyegelan

Drying

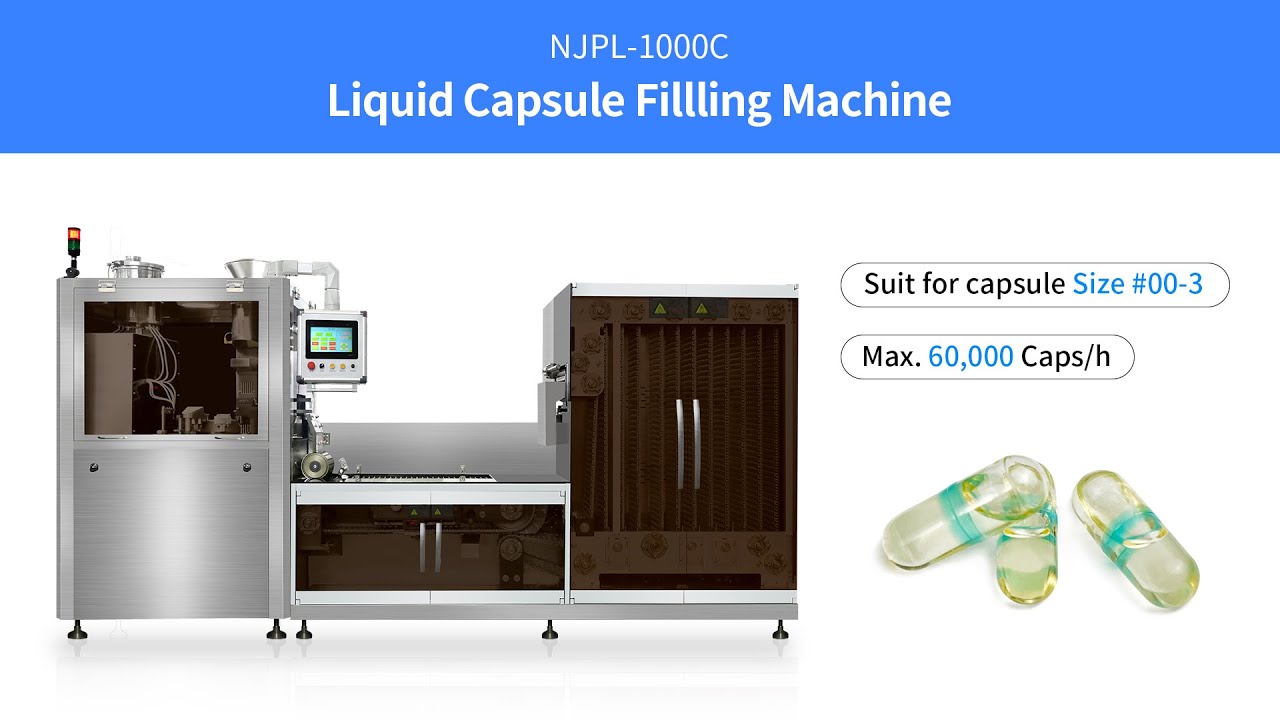

The Complete Range of Liquid Capsule Filling Machines

Berbagai macam model mesin dengan kapasitas dan anggaran berbeda untuk Anda pilih.

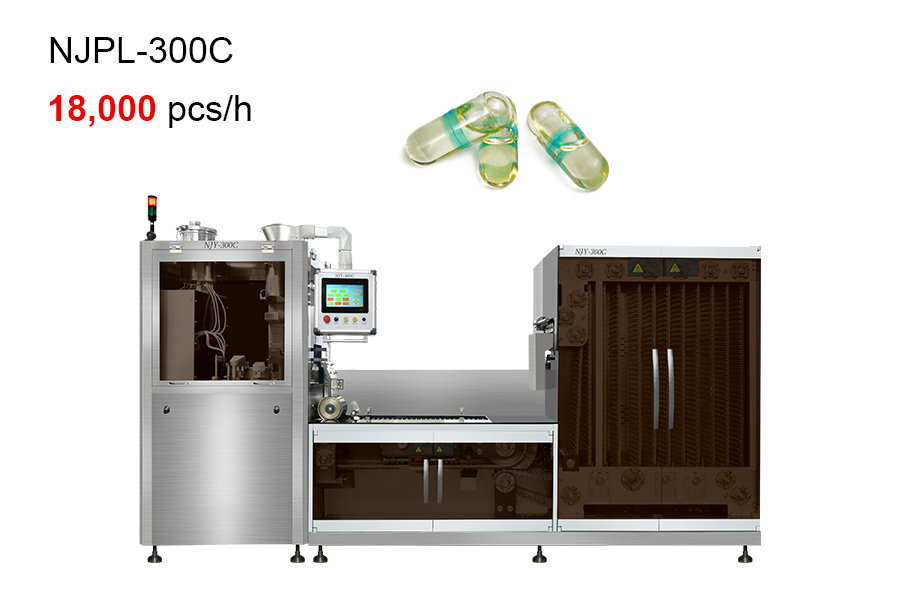

| Model | CGNL-300 | NJPL-100C | NJPL-300C | NJPL-600C |

| Keluaran | 15000-28000 pcs/jam | 100 pcs/menit | 300 pcs/menit | 600 pcs/menit |

| Kompatibilitas Ukuran Kapsul | 00#, 0#, 1#, 2#, 3# | |||

| Daya Total | 2,12 kW | 3,5 KW | 5 KW | 6KW |

| Kekuatan | 380/220V 50Hz (dapat disesuaikan) | |||

| Berat | 400 kg | 500 kg | 750 kg | 900 kg |

| Dimensi (P*L*T) | Ukuran 1300*800*1750mm | Ukuran 700*800*1700mm | Ukuran 860*960*1800mm | Ukuran 960*1000*1900mm |

Tidak yakin mesin mana yang terbaik untuk Anda? Tim kami dapat memberikan proposal berdasarkan kebutuhan dan anggaran Anda!

Mesin Pengisian Kapsul Cairan Otomatis NJPL-330C

NJPL-330C Automatic Liquid Capsule Filling Machine fills and seals oils, suspensions, pastes, and viscous solutions into hard capsules (sizes ...

Investasi Bijak untuk Industri Farmasi

Kami berkomitmen untuk memproduksi mesin dengan kualitas unggul untuk memenuhi standar GMP dengan fitur yang efisien dan bermanfaat.

High accuracy

With Japan’s Yaskawa servo motor, the error of liquid injection is less than 2%. The problem of unevenness caused by the sticky material of is well solved by the ceramic pump.

No Leakage

Equipped with the corresponding sealing liquid according to the type of capsule used by the customer, the sealing is tight and no leakage.

Pollution-free

The rotary design to obtain a patent for utility model. SIL silicone sealing ring effectively prevents liquid into the internal turntable and dust overflow pollution.

Durable Material

All the parts that contact ingredients directly are made of Medical-grade stainless steel 316L, and the output device adopts seven lines with aero aluminum.

Kami Mendukung Anda dengan Layanan Komprehensif

Mendampingi Anda selama seluruh proses, dari memilih mesin yang tepat hingga merawatnya dengan baik seumur hidup.

Garansi Seumur Hidup

Untuk memastikan kinerja premium dalam jangka panjang, kami menawarkan perbaikan gratis dalam jangka waktu 3 tahun dan suku cadang gratis dalam jangka waktu 1 tahun. Setelah itu, kami menjanjikan konsultasi teknis gratis seumur hidup.

Pengiriman Cepat dalam 7 Hari

95% dari mesin standar kami tersedia. Dalam kasus seperti itu, pengiriman dapat dilakukan dalam waktu 7 hari. Sedangkan untuk produk yang disesuaikan secara mendalam, pengiriman hanya memerlukan waktu 20 hari.

Layanan Online 24/7

Para ahli dan teknisi pelanggan kami yang berpengetahuan luas akan menargetkan kebutuhan Anda dan memecahkan semua masalah Anda dalam waktu 24 jam.

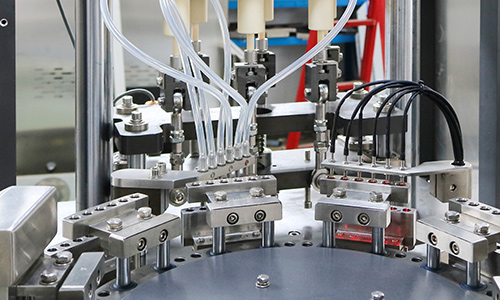

The Main Structure of Liquid Capule Machine

PLC Control System

The machine adopts the internationally famous human-machine interface PLC control system, and the PLC real-time monitoring of the whole operation process is realized, and the automatic capsule and material shortage alarms are realized.

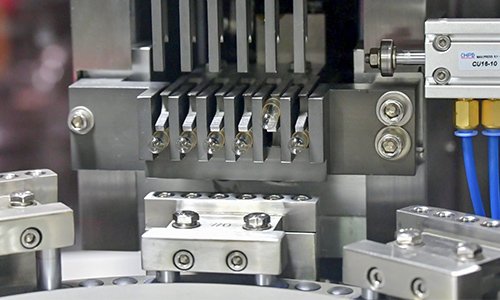

Empty Capsule Filling System

The specially configured capsule feeding machine has a vacuum positioning and separation mechanism to ensure that the capsule loading rate is over 99.5%.

Liquid Injecting System

The accuracy of dosage adopts the liquid adding system of servo motor and high-precision ceramic pump to ensure that the difference of capsule material filling quantity is controlled less than 2%.

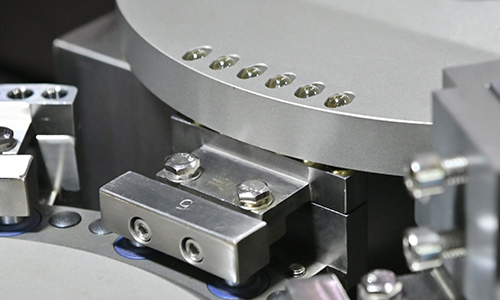

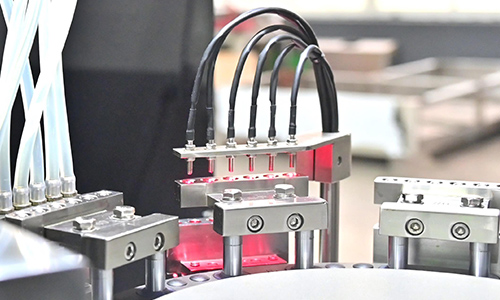

Sealing System

The sealing mechanism of the liquid capsule product adopts a servo motor to control the lifting function, which realizes the up and down jog and the fine adjustment of the rubber wheel, and realizes the best effect of the liquid sealing layer.

Heat Preservation System

The sealing structure is designed in the liquid sealing tank, and the heating and heat preservation system is equipped to ensure the viscosity of the capsule glue.

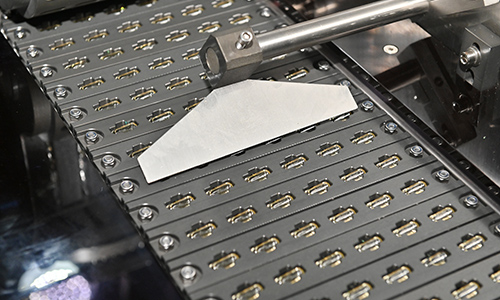

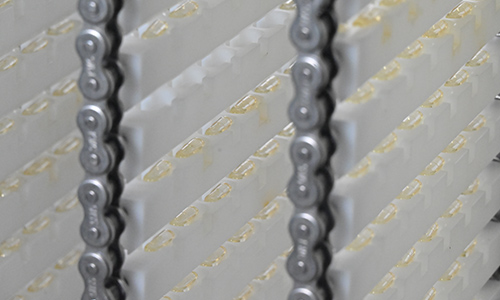

Drying System

The drying mode of the liquid hard capsule finished product adopts a vertical suspension and free rotation structure, which reduces the drying time of the capsule and the installation, disassembly and cleaning time of the capsule filling machine by 50%.

Pertanyaan yang Sering Diajukan

Berikut ini beberapa hal spesifik utama yang perlu Anda pertimbangkan, seperti ukuran dan jenis kapsul, bahan yang digunakan, kapasitas produksi, ukuran mesin, dan garansi. Karena biaya mesin merupakan anggaran yang besar, layanan purnajual yang lengkap dan lama dapat sangat membantu bisnis jangka panjang.

CE: Conformite Europeenne GMP: Praktik Manufaktur yang Baik ISO: Organisasi Standar Internasional FDA: Badan Pengawas Obat dan Makanan

- Lumasi cam secara teratur untuk menjaganya dalam kondisi baik.

- Bongkar dan bersihkan stasiun pengisian untuk membersihkan material berlebih guna mencegah penyumbatan dan karat, setelah produksi selesai.

- Tambahkan oli pelumas ke pompa vakum secara teratur dan bersihkan debu.

- Isi air secukupnya lebih dari separuh badan tong ke dalam tangki air secara teratur.

How to Fill Capsules With Liquid?

Get to know how liquid capsule filling machine works step by step.

1. Capsule Rectification

The liquid capsule filling machine aligns and positions the capsules in the correct orientation for filling. This ensures that the capsules are ready to receive the liquid formulation.

2. Separating Capsule

The machine separates the cap and body components of the capsules. This allows for individual handling of the caps and bodies during the filling process.

3. Filling Liquid

The machine dispenses the liquid formulation into the capsule bodies. The filling parameters, such as volume and speed, are adjustable to ensure accurate and consistent filling.

4. Defects Ejection

The machine inspects the filled capsules for any defects or abnormalities. If a capsule is found to be defective, it is automatically ejected from the production line.

5. Sealing

The machine places the capsule caps onto the filled bodies. The sealing process ensures that the capsules are securely closed and sealed.

6. Drying

This step removes excess moisture or liquid from the capsules. This step removes excess moisture or liquid from the capsules.