Blister crushing during production stems from mechanical misalignment, thermal/pressure imbalances, or material inconsistencies, causing collapsed cavities that compromise product integrity. Below, we dissect its root causes, impacts, and targeted solutions.

1. How Blister Crushing Happens: 4 Core Mechanisms

1.1 Misaligned Tooling Stations

Physics: Forming, sealing, and punching stations operating on different planes exert shear forces.

Critical Threshold: >0.1mm axial offset crushes blister sidewalls during compression.

1.2 Vacuum/Thermoforming Defects

Process Failure: Inconsistent vacuum pressure (below 0.6 bar) creates weak cavity walls.

Heat Transfer Flaws: Uneven heating causes PVC thickness variations (±0.05mm), inducing collapse under sealing pressure.

1.3 Material Fatigue & Incompatibility

Gauge Mismatch: PVC thickness <0.25mm or Alu foil >30μm flexes at sealing temperatures (150–180°C).

Moisture Absorption: Humidity-swollen PVC blisters shrink and deform during cooling.

1.4 Timing Synchronization Errors

Servo Lag: Millisecond delays between forming → sealing stations trap air pockets.

Over-Compression: Premature punch descent crushes unsupported blisters.

2. Production Impacts: Cost, Compliance & Waste

| Area |

Consequence |

Financial Loss |

| Yield Loss |

8–20% rejection rate from crushed tablets |

$2,500–$10,000 per batch |

| Downtime |

30+ mins/hour for manual clearance |

$720/hr (avg. pharma line) |

| Regulatory Risk |

cGMP/ISO non-compliance → failed audits |

$50k+ recall penalties |

| Material Waste |

Ruined PVC/Alu + active ingredients |

15–30% higher material costs |

3. Targeted Solutions: Precision Engineering Fixes

3.1. Eliminate Misalignment

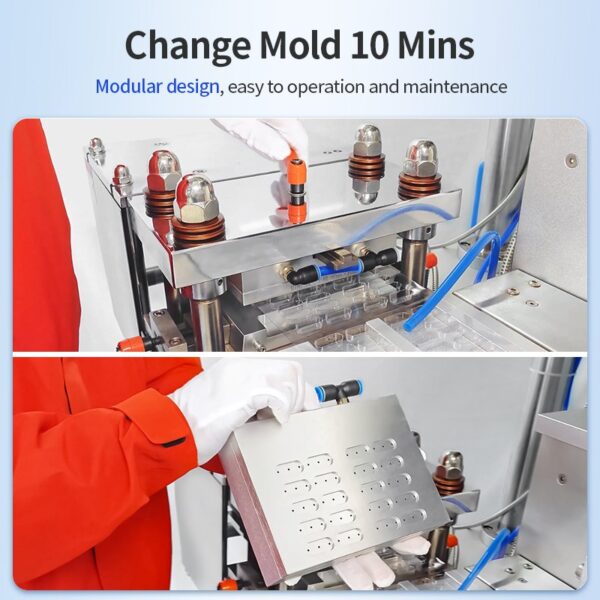

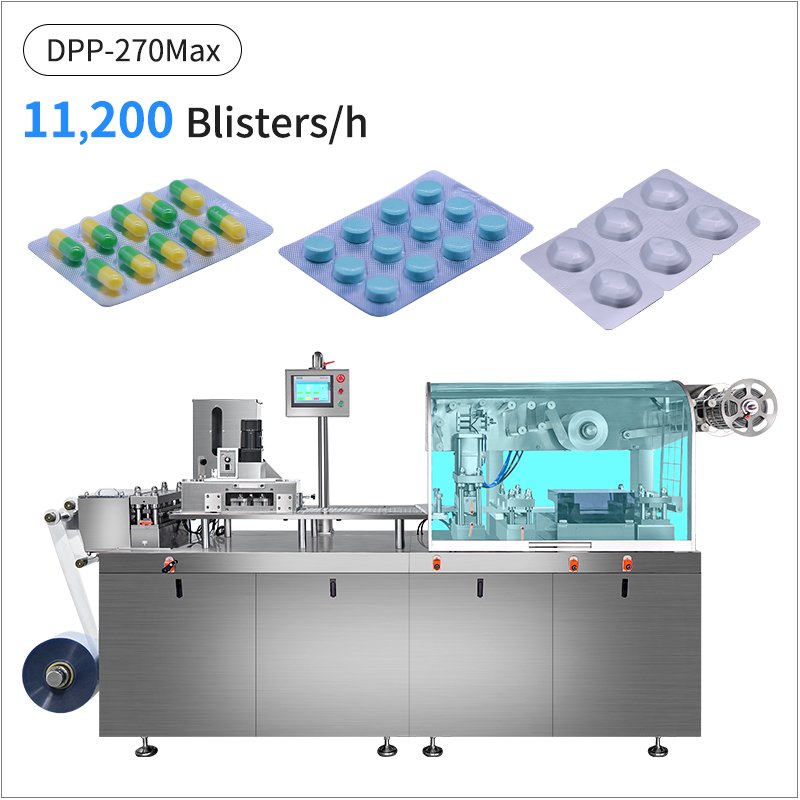

Core-Shaft Technology: Mount forming/sealing/punching stations on a single axis (DPP-180Pro) with handwheel micro-adjustment (<0.01mm tolerance).

Laser-Guided Calibration: Auto-correct misalignment every 500 cycles.

3.2. Optimize Thermoforming

Dynamic Pressure Control: Servo-regulated vacuum pumps maintain 0.7±0.05 bar.

Dual-Stage Heating: Preheat + forming zones ensure uniform PVC ductility.

3.3. Material & Process Controls

Auto-Gauge Sensors: Reject PVC outside 0.25–0.3mm range.

Moisture-Resistant PVC: Use anti-humidity films (tested at 60% RH).

3.4. Synchronization Upgrades

Closed-Loop Servos: Encoder feedback syncs stations within 5ms.

Cavity Support Pins: Micro-pins brace blisters during punching.

Conclusion: Crushing is Preventable with Smart Engineering

Blister crushing originates from machine misalignment, uncontrolled thermoforming, or substandard materials—not inevitability. Implementing unified-axis tooling, servo-driven pressure control, and real-time monitoring reduces defects by 95%. Machines like the DPP-180Pro demonstrate this via near-zero rejection rates in cGMP facilities, proving that precision design eliminates while boosting ROI.