Stick filling machine automate the packaging of granular, powdery, liquid, paste, and solid products (e.g., snacks, candy, pet food, detergent, spices) into pre-made, stand-up pouches (pillow bags, 3/4-side seal bags) from a continuous roll of film.

Ruida Packing’s RD-SPM-480 6-Lane back sealed sachet packing machine sets a new benchmark for high-speed pharmaceutical powder packaging. Combining servo precision with GMP-compliant engineering, this system delivers unmatched accuracy from film unwinding to final product discharge. Here’s how it achieves ±0.1% dosing accuracy while meeting strict regulatory standards.

1. Working Principle

1.1 Film Unwinding & Tension Control

A roll of multi-layered packaging film (PET/PE, OPP/CPP, Alu/PE) is mounted on the machine’s unwind shaft. A tension control system (brakes, sensors, dancer rolls) maintains constant, optimal film tension to prevent wrinkles, stretching, or slack.

1.2 Film Guidance & Printing (Optional)

The film passes through guide rollers, ensuring smooth, aligned entry into the forming section. If required, a date/batch code printer (thermal transfer, inkjet, ribbon) marks the film at a precise location.

1.3 Film Forming

This precision metal shapes the film into a continuous, vertical tube by folding/bending it. The film edges are positioned either overlapping or butting, ready for the longitudinal seal.

1.4 Longitudinal (Vertical) Sealing

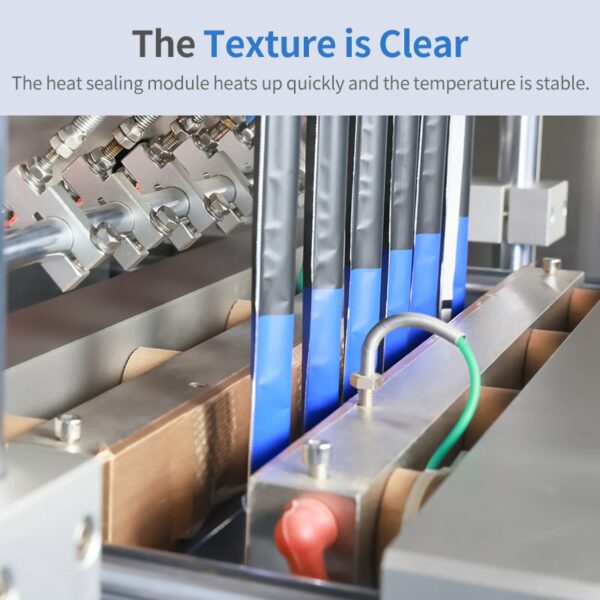

Immediately after forming, the overlapping film edges pass through the longitudinal sealer. Heated belts apply controlled heat, pressure, and dwell time. The film’s inner heat-seal layer melts, creating a strong, continuous back seal (one side of the finished bag).

1.5 Product Filling

The sealed film tube continues downward. Below the longitudinal seal point, servo screw (coaxial with the forming collar) dispenses a pre-measured product dose into the sachet. Dosing is done via augers. Gravity aids product flow. Filling occurs below the seal to avoid contamination.

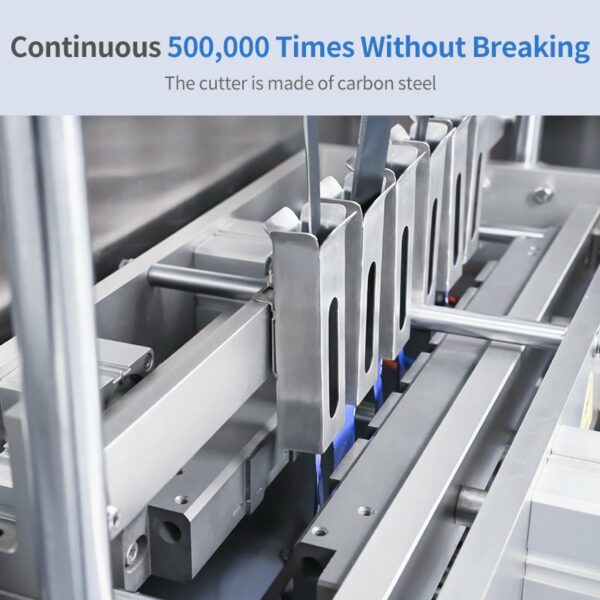

1.6 Transverse Sealing & Cutting

The jaws clamp tightly, applying heat and pressure. Creates two seals at once. The TOP seal of the lower bag (being filled). The BOTTOM seal of the upper bag (just filled). A blade (hot knife, serrated, cold cut) integrated between the jaws severs the film between these two seals. This separates the finished upper bag and leaves the lower bag open at the top for the next fill.

1.7 Finished Bag Discharge

The separated, sealed bags are conveyed away for collection or downstream processing (checkweigher, metal detector, embalagem de papelão).

2. Advantages

2.1 High Efficiency & Continuous Operation

Uses continuous roll film, eliminating frequent stops for pre-made bags. Very high speeds (often 200+ bags/minute), ideal for mass production.

2.2 Flexible Pouch Styles

Can produce 3-side seal and 4-side seal bags with tooling changes. Adjustable pouch length and width (via forming collar change).

2.3 Wide Material Compatibility

Handles various laminated roll films: single/multi-layer plastics, metallized films, aluminum laminates, paper composites. Suits diverse barrier, strength, print, and seal requirements.

2.4 Broad Product Applicability

Packages diverse forms: granules, powders, liquids, pastes, solids, flakes, chunks. Widely used in Pharma (powders), Food (snacks, frozen goods, coffee, spices), FMCG (detergents, samples), Pet Food, Hardware, and Chemicals.

2.5 High Automation

Fully integrates film handling, forming, filling, sealing, coding (optional), cutting, and discharge. Easily integrated with upstream feeders (weigh scales, auger fillers, liquid pumps) and downstream systems (checkweighers, case packers).

2.6 Material & Cost Efficiency

Roll film generates less waste compared to pre-formed pouches. Compact storage and transport of film rolls reduces costs.

2.7 Reliable Sealing

Controlled heat, pressure, and time ensure strong, hermetic longitudinal and transverse seals for product protection and extended shelf life.

2.8 Photoelectric Mark Alignment

Our high-resolution optical sensors scan registration marks at 200 scans/second. This enables closed-loop feedback to dynamically adjust film position in real-time:

Uncompromising Positional Accuracy: Ensures tear notches align within ±0.3mm tolerance while maintaining print graphic consistency.

Zero Material Waste: Eliminates misalignment-related film rejection.

Process Reliability: Guarantees every pouch maintains identical functional and aesthetic properties.

3. Limitations

Product Constraints: Less suitable for very long, heavy, fragile, easily crushed, or extremely irregularly shaped items that may jam in the tube or filler.

Changeover Complexity: Changing pouch width requires replacing the forming collar, involving downtime and operator skill.

Initial Investment: Higher upfront cost compared to simple manual/semi-auto machines.

Film Quality Dependency: Requires consistent, high-quality film roll stock. Print registration, tension control, and seal layer performance are critical for reliable operation.

Stick pack form fill sealing machine excel at high-speed, automated production of stand-up pouches through their unique vertical tube-forming, filling, and sealing process. Key strengths include efficiency, pouch versatility (especially stand-up capability), broad material/product compatibility, automation, and material savings. Selection requires careful consideration of product specifics, production volume, film type, budget, and automation needs.