- Lar

- Máquina de enchimento de cápsulas

- Máquina de enchimento de cápsulas líquidas

Máquina de enchimento de cápsulas líquidas

This liquid capsule machine is fully automatic to fill and seal the liquid and other materials into empty hard capsules.

Ela fornece uma solução farmacêutica altamente ativa e insolúvel para embalagem de materiais líquidos para muitas empresas farmacêuticas grandes e pequenas e fabricantes de produtos para cuidados de saúde.

Capable Capsule sizes:

Liquid capsule filling machine is available in 8 kinds of standard capsule sizes.

|  |  |  |  | |

| Capsule Size | #00 | #0 | #1 | #2 | #3 |

| Locked Length | 23.30mm | 21.7mm | 19.4mm | 18.0mm | 15.9mm |

| Capsule Volume | 0.91 ml | 0.68 ml | 0.5 ml | 0.37 ml | 0.3 ml |

(The filling amount may vary because of the powder difference)

Como funciona

Além de simplesmente injetar o ingrediente líquido em uma cápsula, a máquina de enchimento de cápsulas com líquido rico é equipada com seções de trabalho e tecnologias para garantir um processo de produção suave e eficiente.

Capsule Rectification

Separating Caps & Bodies

Filling Liquid

Defective Capsules Ejection

Selagem

Drying

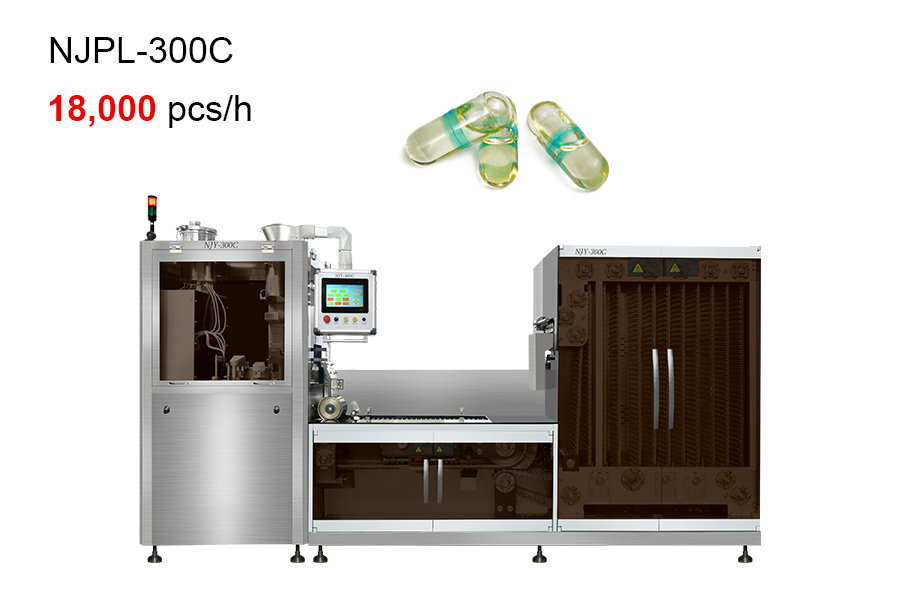

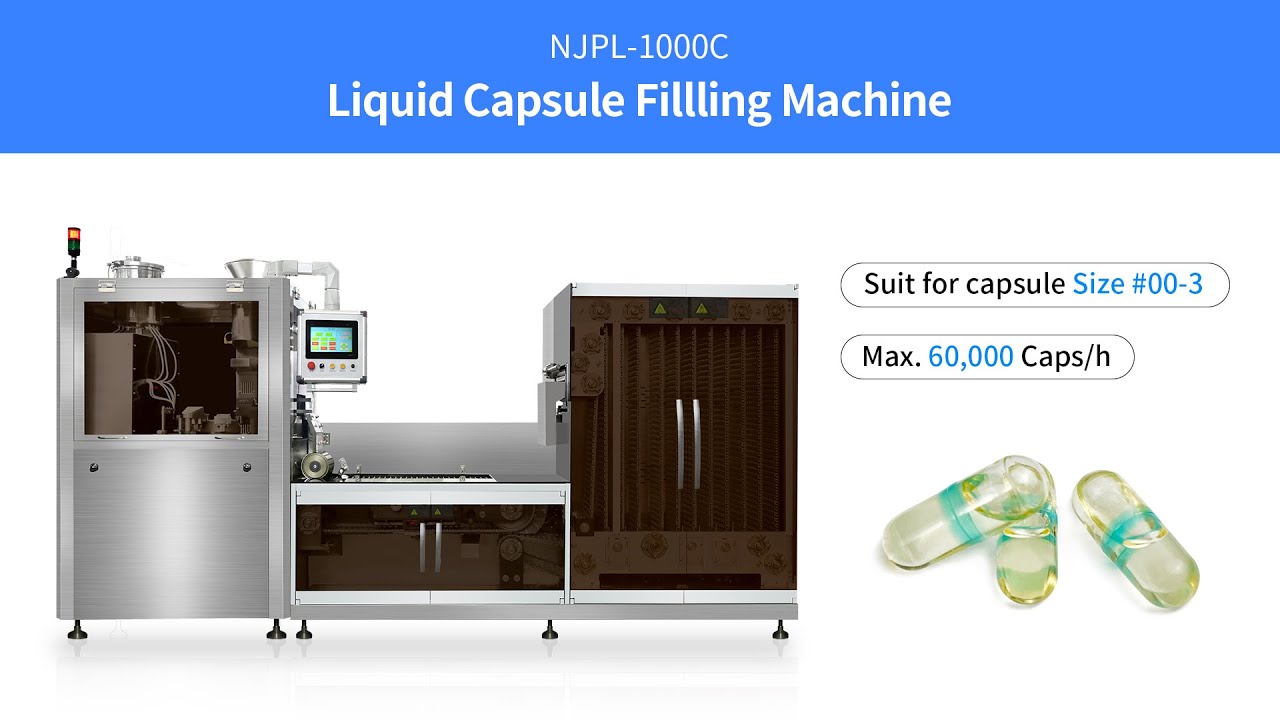

The Complete Range of Liquid Capsule Filling Machines

A wide variety of machine models with different capacities and budgets for you to choose from.

| Modelo | CGNL-300 | NJPL-100C | NJPL-300C | NJPL-600C |

| Saída | 15000-28000pcs/h | 100 peças/min | 300 peças/min | 600 peças/min |

| Compatibilidade de tamanhos de cápsulas | 00#, 0#, 1#, 2#, 3# | |||

| Potência total | 2,12 kW | 3,5KW | 5KW | 6KW |

| Poder | 380/220V 50Hz (personalizável) | |||

| Peso | 400KG | 500KG | 750KG | 900KG |

| Dimensão (L*W*H) | 1300*800*1750mm | 700*800*1700mm | 860*960*1800mm | 960*1000*1900mm |

Não tem a certeza de qual a melhor máquina para si? A nossa equipa pode apresentar uma proposta com base nas suas necessidades e orçamento!

Máquina de enchimento de cápsulas líquidas automática NJPL-330C

A máquina automática de enchimento de cápsulas para líquidos NJPL-330C enche e sela óleos, suspensões, pastas e soluções viscosas em cápsulas duras (tamanhos ...

Um investimento inteligente para a indústria farmacêutica

Estamos comprometidos em fabricar máquinas com qualidade superior para atender aos padrões GMP, além de recursos eficientes e utilitários.

High accuracy

With Japan’s Yaskawa servo motor, the error of liquid injection is less than 2%. The problem of unevenness caused by the sticky material of is well solved by the ceramic pump.

No Leakage

Equipped with the corresponding sealing liquid according to the type of capsule used by the customer, the sealing is tight and no leakage.

Pollution-free

The rotary design to obtain a patent for utility model. SIL silicone sealing ring effectively prevents liquid into the internal turntable and dust overflow pollution.

Durable Material

All the parts that contact ingredients directly are made of Medical-grade stainless steel 316L, and the output device adopts seven lines with aero aluminum.

Nós cuidamos de você com um serviço completo

Acompanhamos você durante todo o processo, desde a escolha da máquina adequada até os cuidados necessários para o resto da vida.

Garantia vitalícia

Para garantir um desempenho premium por muito tempo, oferecemos reparo gratuito em até 3 anos e peças de reposição gratuitas em até 1 ano. Após esse período, garantimos uma consultoria técnica gratuita por toda a vida.

Entrega rápida em 7 dias

Temos 95% de nossas máquinas padrão em estoque. Nesse caso, a entrega pode ser feita em até 7 dias. Para produtos personalizados, o prazo de entrega é de apenas 20 dias.

Serviço online 24 horas por dia, 7 dias por semana

Nossos experientes engenheiros e especialistas em atendimento ao cliente atenderão às suas necessidades e resolverão todos os seus problemas em 24 horas.

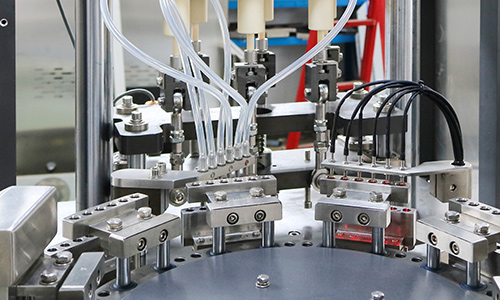

The Main Structure of Liquid Capule Machine

PLC Control System

The machine adopts the internationally famous human-machine interface PLC control system, and the PLC real-time monitoring of the whole operation process is realized, and the automatic capsule and material shortage alarms are realized.

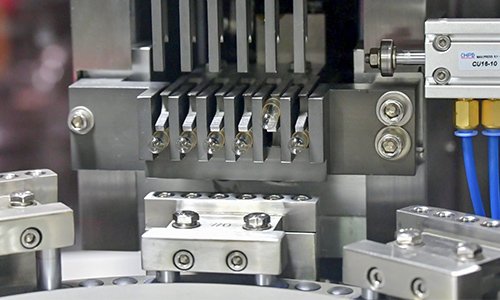

Empty Capsule Filling System

The specially configured capsule feeding machine has a vacuum positioning and separation mechanism to ensure that the capsule loading rate is over 99.5%.

Liquid Injecting System

The accuracy of dosage adopts the liquid adding system of servo motor and high-precision ceramic pump to ensure that the difference of capsule material filling quantity is controlled less than 2%.

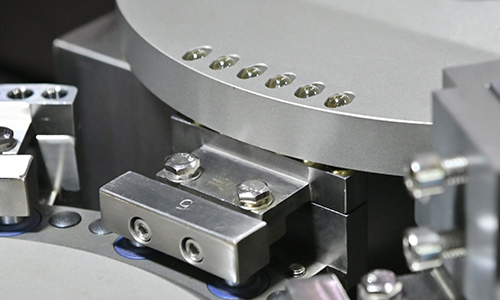

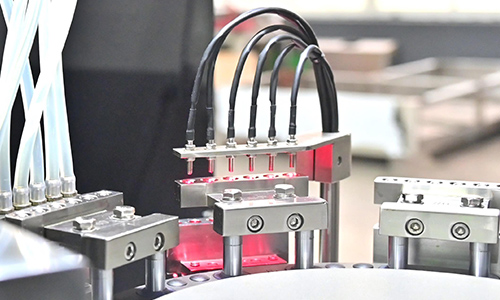

Sealing System

The sealing mechanism of the liquid capsule product adopts a servo motor to control the lifting function, which realizes the up and down jog and the fine adjustment of the rubber wheel, and realizes the best effect of the liquid sealing layer.

Heat Preservation System

The sealing structure is designed in the liquid sealing tank, and the heating and heat preservation system is equipped to ensure the viscosity of the capsule glue.

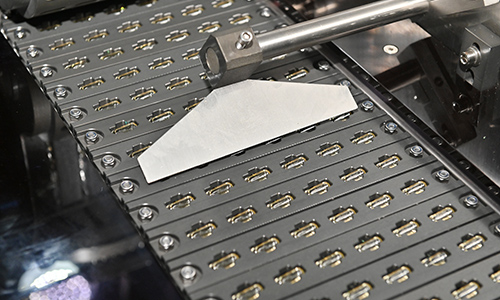

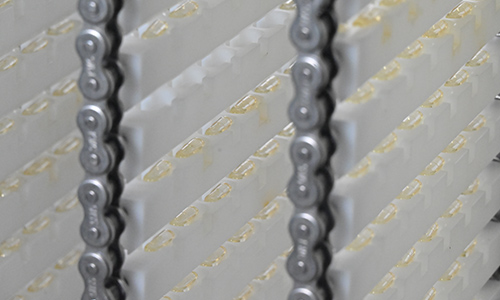

Drying System

The drying mode of the liquid hard capsule finished product adopts a vertical suspension and free rotation structure, which reduces the drying time of the capsule and the installation, disassembly and cleaning time of the capsule filling machine by 50%.

Perguntas frequentes

Here are some main specifics that you need to consider, such as capsule size and type, applicable ingredient, production capacity, machine size, and warranty. Due to the cost of the machine is a huge budget, a complete and long aftersale service can help a lot for a long run business.

CE: Conformidade Europeia GMP: Boas Práticas de Fabricação ISO: Organização Internacional de Padronização FDA: Administração de Alimentos e Medicamentos

- Lubrificar regularmente o excêntrico para o manter em bom estado.

- Desmontar e limpar a estação de enchimento para retirar o excesso de material, a fim de evitar entupimentos e ferrugem, após a conclusão da produção.

- Adicionar regularmente óleo lubrificante à bomba de vácuo e limpar o pó.

- Encher regularmente o depósito de água com água suficiente para cobrir metade do corpo do barril.

How to Fill Capsules With Liquid?

Get to know how liquid capsule filling machine works step by step.

1. Capsule Rectification

The liquid capsule filling machine aligns and positions the capsules in the correct orientation for filling. This ensures that the capsules are ready to receive the liquid formulation.

2. Separating Capsule

The machine separates the cap and body components of the capsules. This allows for individual handling of the caps and bodies during the filling process.

3. Filling Liquid

The machine dispenses the liquid formulation into the capsule bodies. The filling parameters, such as volume and speed, are adjustable to ensure accurate and consistent filling.

4. Defects Ejection

The machine inspects the filled capsules for any defects or abnormalities. If a capsule is found to be defective, it is automatically ejected from the production line.

5. Sealing

The machine places the capsule caps onto the filled bodies. The sealing process ensures that the capsules are securely closed and sealed.

6. Drying

This step removes excess moisture or liquid from the capsules. This step removes excess moisture or liquid from the capsules.