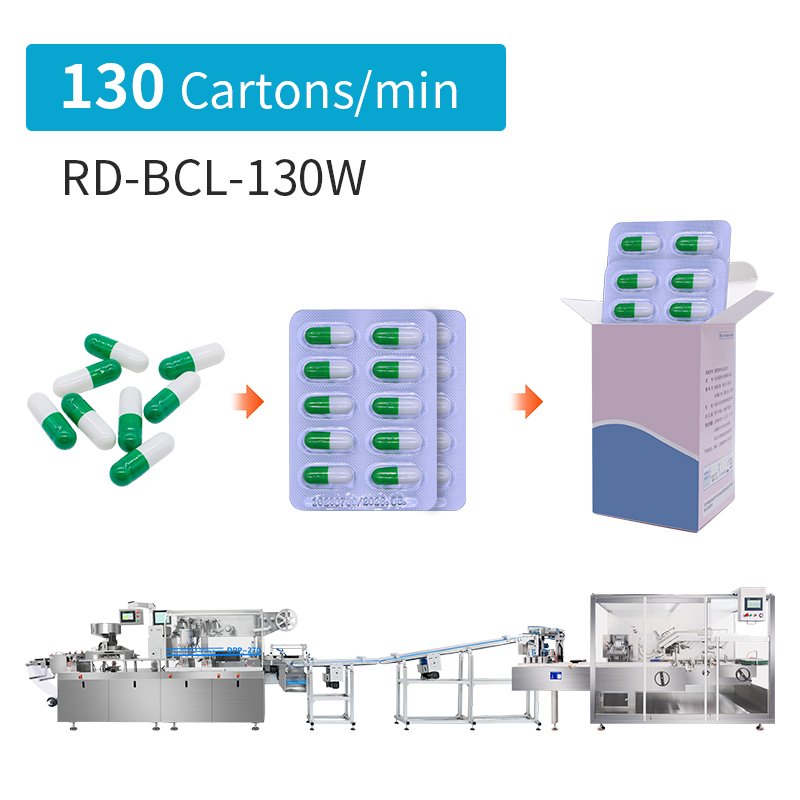

Maszyny napełniające saszetki automatyzują pakowanie produktów granulowanych, proszkowych, płynnych, past i stałych (np. przekąsek, słodyczy, karmy dla zwierząt, detergentów, przypraw) do gotowych, stojących torebek (torebek typu poduszka, torebek ze zgrzewem 3/4 boku) z ciągłej rolki folii.

6-ścieżkowa maszyna pakująca saszetki z odwrotnym zamknięciem RD-SPM-480 firmy Ruida Packing wyznacza nowy standard w zakresie szybkiego pakowania proszków farmaceutycznych. Łącząc precyzję serwomotorów z inżynierią zgodną z GMP, system ten zapewnia niezrównaną precyzję od rozwijania folii do wydawania produktu końcowego. Oto, jak osiąga dokładność dozowania ±0,1%, spełniając jednocześnie surowe normy.

1. Zasada działania

1.1 Odwijanie folii i kontrola naciągu

Rolka wielowarstwowej folii opakowaniowej (PET/PE, OPP/CPP, Alu/PE) jest zamontowana na wałku odwijającym maszyny. System kontroli naciągu (hamulce, czujniki, rolki tańczące) utrzymuje stałe, optymalne naprężenie folii, zapobiegając powstawaniu zagnieceń, rozciąganiu i luzowaniu.

1.2 Wskazówki dotyczące folii i drukowania (opcjonalnie)

Folia przechodzi przez rolki prowadzące, zapewniając płynne i równe wejście do sekcji formującej. W razie potrzeby drukarka z datą/kodem partii (termotransferowa, atramentowa, taśma barwiąca) znakuje folię w precyzyjnym miejscu.

1.3 Tworzenie filmu

Ten precyzyjny metal formuje folię w ciągłą, pionową rurę poprzez jej składanie/gięcie. Krawędzie folii są ustawione na zakładkę lub stykają się ze sobą, przygotowując się do zgrzewu wzdłużnego.

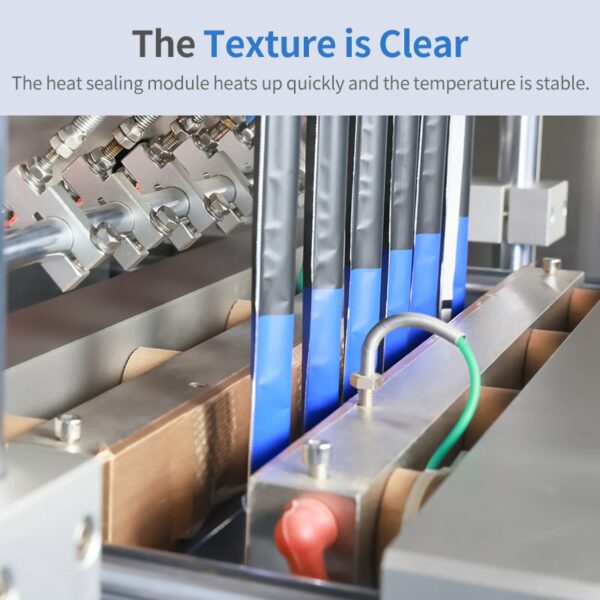

1.4 Uszczelnianie wzdłużne (pionowe)

Natychmiast po uformowaniu, nakładające się na siebie krawędzie folii przechodzą przez zgrzewarkę wzdłużną. Podgrzewane pasy zapewniają kontrolowaną temperaturę, nacisk i czas zgrzewania. Wewnętrzna warstwa zgrzewana termicznie folii topi się, tworząc mocne, ciągłe zgrzewy tylne (jedna strona gotowej torebki).

1.5 Napełnianie produktem

Zgrzana tuba foliowa przesuwa się w dół. Poniżej punktu zgrzewu podłużnego, serwoślimak (współosiowy z kołnierzem formującym) dozuje wstępnie odmierzoną dawkę produktu do saszetki. Dozowanie odbywa się za pomocą ślimaków. Grawitacja wspomaga przepływ produktu. Napełnianie odbywa się poniżej zgrzewu, aby uniknąć zanieczyszczenia.

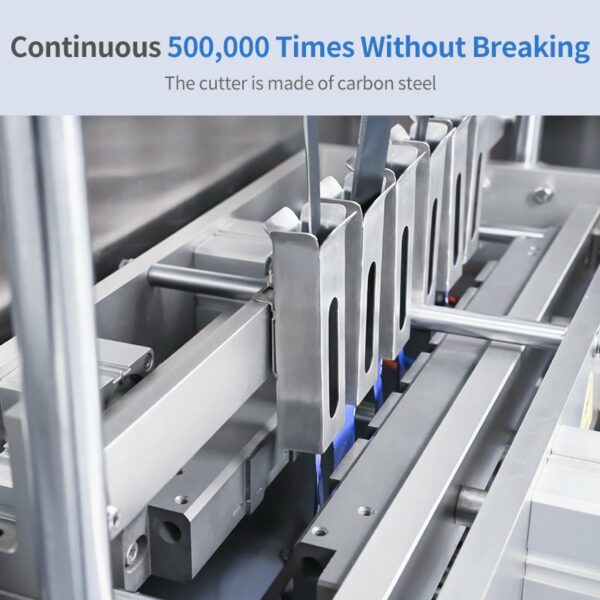

1.6 Uszczelnianie i cięcie poprzeczne

Szczęki zaciskają się mocno, stosując ciepło i nacisk. Tworzą dwa zgrzewy jednocześnie. GÓRNY zgrzew dolnego worka (w trakcie napełniania). DOLNY zgrzew górnego worka (właśnie napełnionego). Ostrze (gorący nóż, ząbkowane, cięte na zimno) zintegrowane między szczękami przecina folię między tymi dwoma zgrzewami. To rozdziela gotowy górny worek, a dolny worek pozostaje otwarty u góry, aby można było go napełnić ponownie.

1.7 Wyładunek gotowego worka

Oddzielone, zamknięte worki są transportowane do odbioru lub dalszego przetwarzania (waga kontrolna, wykrywacz metali, pakowanie w kartony).

2. Zalety

2.1 Wysoka wydajność i ciągła praca

Wykorzystuje folię w rolkach, eliminując częste przestoje w przypadku gotowych toreb. Bardzo duża prędkość (często ponad 200 toreb na minutę), idealna do produkcji masowej.

2.2 Elastyczne style torebek

Możliwość produkcji torebek zgrzewanych z trzech i czterech stron po zmianie narzędzi. Regulowana długość i szerokość torebki (poprzez zmianę kołnierza formującego).

2.3 Szeroka kompatybilność materiałowa

Obsługuje różne laminowane folie rolkowe: tworzywa sztuczne jedno- i wielowarstwowe, folie metalizowane, laminaty aluminiowe, kompozyty papierowe. Spełnia zróżnicowane wymagania dotyczące bariery, wytrzymałości, nadruku i uszczelnienia.

2.4 Szerokie zastosowanie produktu

Opakowania w różnych formach: granulaty, proszki, płyny, pasty, produkty stałe, płatki, kawałki. Szeroko stosowane w przemyśle farmaceutycznym (proszki), spożywczym (przekąski, mrożonki, kawa, przyprawy), FMCG (detergenty, próbki), karmach dla zwierząt, sprzęcie i chemikaliach.

2.5 Wysoka automatyzacja

W pełni integruje obsługę folii, formowanie, napełnianie, zamykanie, kodowanie (opcjonalnie), cięcie i rozładowywanie. Łatwa integracja z podajnikami wstępnymi (wagi, dozowniki ślimakowe, pompy do cieczy) i systemami końcowymi (wagi kontrolne, pakowarki do kartonów).

2.6 Efektywność materiałowa i kosztowa

Folia w rolkach generuje mniej odpadów w porównaniu z gotowymi woreczkami. Kompaktowe przechowywanie i transport rolek folii obniża koszty.

2.7 Niezawodne uszczelnienie

Kontrolowane ciepło, ciśnienie i czas zapewniają mocne, hermetyczne uszczelnienia wzdłużne i poprzeczne, chroniąc produkt i wydłużając jego okres przydatności do spożycia.

2.8 Wyrównanie znaczników fotoelektrycznych

Nasze czujniki optyczne o wysokiej rozdzielczości skanują znaki rejestracyjne z prędkością 200 skanów na sekundę. Dzięki temu, dzięki zamkniętej pętli sprzężenia zwrotnego, można dynamicznie regulować położenie filmu w czasie rzeczywistym:

Bezkompromisowa dokładność pozycjonowania: gwarantuje, że nacięcia będą się pokrywać z tolerancją ±0,3 mm, przy jednoczesnym zachowaniu spójności graficznej druku.

Zero odpadów materiałowych: eliminuje odrzuty folii spowodowane nieprawidłowym wyrównaniem.

Niezawodność procesu: gwarantuje, że każda torebka zachowuje identyczne właściwości funkcjonalne i estetyczne.

3. Ograniczenia

Ograniczenia produktu: Mniej odpowiedni do bardzo długich, ciężkich, delikatnych, łatwo zgniatanych lub o wyjątkowo nieregularnych kształtach przedmiotów, które mogą zaciąć się w tubie lub wypełniaczu.

Złożoność zmiany: Zmiana szerokości torebki wymaga wymiany kołnierza formującego, co wiąże się z przestojem i wymaga umiejętności operatora.

Początkowa inwestycja: wyższe koszty początkowe w porównaniu do prostych maszyn ręcznych/półautomatycznych.

Zależność od jakości folii: Wymaga spójnego, wysokiej jakości materiału w rolkach. Dopasowanie nadruku, kontrola naciągu i wydajność warstwy uszczelniającej są kluczowe dla niezawodnej pracy.

Maszyny do formowania, napełniania i zamykania saszetek stick pack wyróżniają się szybką, zautomatyzowaną produkcją saszetek stojących dzięki unikalnemu pionowemu procesowi formowania, napełniania i zamykania. Do ich kluczowych zalet należą: wydajność, wszechstronność saszetek (zwłaszcza możliwość pakowania w saszetki stojące), szeroka kompatybilność materiałowa/produktowa, automatyzacja i oszczędność materiału. Wybór wymaga starannego rozważenia specyfiki produktu, wielkości produkcji, rodzaju folii, budżetu oraz potrzeb w zakresie automatyzacji.