Een pillenteller is essentiële apparatuur in de farmaceutische verpakkingsindustrie. Pillentellermachines tellen en sorteren nauwkeurig tabletten, capsules en zachte gels van verschillende vormen en groottes, en verpakken deze medicijnen uiteindelijk in flessen of zakjes, zodat de distributie van medicijnen nauwkeurig verloopt.

Moderne farmaceutische tel- en verpakkingsmachines maken gewoonlijk gebruik van tabletten telmachines die zijn uitgerust met infrarode foto-elektrische sensoren, waardoor de nauwkeurigheid van de medicatiehoeveelheid hoger is dan 99% per verpakking. Bovendien overtreft een geavanceerde vision-gebaseerde pillentelmachine die gebruik maakt van high-speed cameratechnologie deze prestaties, waardoor de telnauwkeurigheid oploopt tot 99,99%.

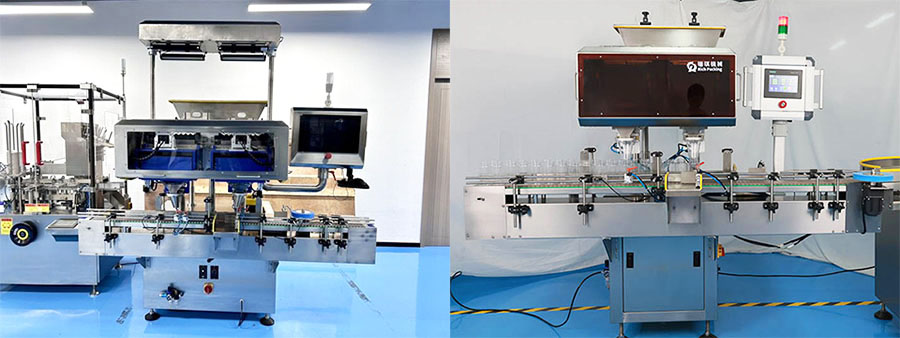

een telmachine met vision (links) en een telmachine met infrarood (rechts)

1. Primaire categorieën van pillentelmachines

Apparatuur voor het tellen van pillen wordt grofweg ingedeeld in drie hoofdtypen op basis van automatiseringsniveau en technische geavanceerdheid, die elk voldoen aan verschillende operationele behoeften in de farmaceutische productie.

een pillentelmachine die zachte gelcapsules naar opeenvolgende telkanalen transporteert

- Semi-auto tablet balie machines: Vertegenwoordigen een overgangsoplossing tussen handmatig en volledig automatisch tellen van pillen. Hoewel het eigenlijke telproces geautomatiseerd is, vereisen deze machines handmatige invoer van tabletten, capsules of softgels in de trechter. Dit type tabletten telmachine biedt een aanzienlijke snelheidsverbetering ten opzichte van puur handmatig tellen en vermindert menselijke fouten bij het tellen zelf. Het feit dat de machines afhankelijk zijn van de operator voor de materiaaltoevoer beperkt echter hun totale doorvoer.

- Volledig automatisch tablettellermachines: Volautomatische tellers voor pillen en capsules zijn ontworpen voor de productie van grote hoeveelheden farmaceutische producten en leveren een aanzienlijke efficiëntiewinst op. Veel van deze telmachines maken gebruik van technologieën zoals infrarode foto-elektrische sensoren voor contactloos tellen en hebben vaak geïntegreerde real-time controlesystemen. Deze tabletten tellers kunnen automatisch veelvoorkomende operationele fouten detecteren en signaleren, zoals vastzittende capsules of een abnormaal pillenverloop. Cruciaal is dat hun hoge telnauwkeurigheid wordt aangevuld met geavanceerde connectiviteitsopties, waardoor een capsule telmachine naadloos kan worden geïntegreerd in een complete, geautomatiseerde verpakkingslijn naast apparatuur voor het vullen, aftoppen en etiketteren van flessen.

het hoofdmechanisme van een volledig automatische pillentellermachine

- Professioneel high-een tabletten telmachines: Maak gebruik van de meest geavanceerde technologieën voor ultieme precisie en betrouwbaarheid, vooral in kritieke toepassingen. Een belangrijk kenmerk is de integratie van high-speed cameravisiesystemen, die ultrasnelle beeldvorming en een hoge resolutie gebruiken om elke afzonderlijke pil of capsule vast te leggen en te analyseren, waardoor de telnauwkeurigheid aanzienlijk wordt verbeterd, vooral bij lastige pilvormen of transparante capsules.

Prominente fabrikanten van farmaceutische en verpakkingsmachines zoals Romaco en Ruida Packing streven naar voortdurende innovatie om gevalideerde nauwkeurigheid en stabiliteit te bereiken bij het tellen en vullen van tabletten.

Ruida Packing illustreert deze toewijding met een divers aanbod van geavanceerde tablettellers met zowel betrouwbare infrarode foto-elektrische sensoren als geavanceerde vision-systemen met hoge snelheid voor het tellen. Cruciaal is dat de telmachines van deze leverancier schaalbare oplossingen bieden met meertraps trilkanalen, variërend van compacte 8-kanaalsmodellen die ideaal zijn voor laboratoria of apotheken tot 48-kanaalssystemen met hoge capaciteit, ontworpen voor grootschalige farmaceutische productie. Deze veelzijdigheid zorgt voor nauwkeurig, snel tellen en vullen van onregelmatig gevormde tabletten, zachte/harde capsules en zelfs transparante capsules.

Ruida Packing toonde zijn vision-gebaseerde pillentellermachine op CPhI Expo 2025

Deze ervaren leverancier van farmaceutische apparatuur erkent de unieke uitdagingen in zoetwaren en heeft daarom gespecialiseerde modellen voor snoeptelmachines ontwikkeld die kleverige, gecoate (suiker, olie, zand) snoepjes aanpakken met behulp van een reeks anti-verstoppingsmechanismen, waaronder vultrechterroerders, scheidingsrollen voor snoepjes en speciaal ontworpen Teflon gecoate trilplaten met regendruppels, zodat zelfs het meest uitdagende, viskeuze materiaal soepel en ononderbroken geteld en gevuld kan worden.

2. Waarom heb je een vision-gebaseerde telmachine nodig naast een infrarood-pillenteller?

Vergeleken met een op infrarood gebaseerd pillentelapparaat dat pillen telt door de kortstondige blokkering van een infrarode lichtstraal te detecteren die door elke vallende pil wordt veroorzaakt, is een op zicht gebaseerd pillentellermodel relatief zeldzaam op de markt.

2.1 Wat zijn deze twee soorten telmachines?

Een vision-gebaseerde tabletten-telmachine is een type farmaceutische apparatuur dat camerasystemen gebruikt om visueel tabletten, capsules of pillen te identificeren, tellen en controleren. In plaats van mechanische of infraroodsensoren maakt de machine beelden met hoge resolutie van pillen en capsules op een telband, waarna beeldverwerkingsalgoritmen worden gebruikt om elke eenheid te detecteren en te tellen op basis van de visuele kenmerken (bijv. vorm, grootte, kleur of oppervlaktemarkeringen).

Een op infrarood gebaseerde pillentelmachine, die vaak gezien wordt op de markt van automatische telmachines, is een type geautomatiseerde apparatuur dat gebruik maakt van infrarode (IR) lichtstralen en sensoren om individuele farmaceutische items zoals tabletten, capsules of softgels te tellen terwijl ze door een aangewezen pad gaan. In detail projecteert een infrarood lichtzender een onzichtbare lichtstraal over een kanaal waar pillen doorheen vallen. Wanneer er geen pil aanwezig is, bereikt de IR-straal de sensor. Als er een pil valt, blokkeert deze de IR-straal. Elke keer dat de straal wordt geblokkeerd, registreert de sensor dit als een enkele telling.

het belangrijkste mechanisme van een vision-gebaseerde pillenteller

2.2 Wat zijn de voordelen van een vision-gebaseerde machine voor het tellen van pillencapsules?

Ter vergelijking: een op zicht gebaseerde machine voor het tellen van tabletcapsules heeft duidelijke voordelen ten opzichte van een op infrarood (IR) gebaseerde machine voor het tellen van tabletten:

|

Voordeelgebied |

Op visie gebaseerde pillenteller |

Op IR gebaseerde pillenteller |

|

Vorm Verwerken |

Telt nauwkeurig onregelmatige, niet-uniforme of beschadigde pillen met behulp van vormherkenning en morfologische analyse. |

Heeft moeite met niet-sferische of beschadigde items; vertrouwt op consistent onderbrekingsprofiel. |

|

Transparantie |

Telt volledig transparante capsules of softgels door randen/kenmerken optisch te detecteren. |

Lukt vaak niet met transparante voorwerpen omdat IR-licht ononderbroken doorgelaten wordt. |

|

Oppervlaktedetectie |

Detecteert defecten in het oppervlak van medicijnen (spanen, barsten, vervuiling) via beeldanalyse. |

Detecteert alleen de aanwezigheid/afwezigheid van pillen; kan de kwaliteit van het medicijnoppervlak niet inspecteren. |

|

Telsnelheid |

Niet-onderbrekende methode: Telt zonder fysieke onderbreking of onderbreking van de bundel → hogere maximumsnelheden mogelijk. |

Onderbrekende methode: Vereist fysieke blokkering van de straal → beperkt maximale snelheid en risico op vastlopen. |

|

Resolutie voor meerdere items |

Lost gestapelde pillen op via geavanceerde beeldverwerking (bijv. AI-segmentatie). |

Telt gestapelde pillen als één pil als ze samen de balk blokkeren → ondertelt. |

|

Verificatievermogen |

Controleert de identiteit van de pillen (kleuren, markeringen, afmetingen) aan de hand van een referentieafbeeldingenbibliotheek. |

Geen verificatiemogelijkheid; telt alleen onderbrekingen, ongeacht het type. |

|

Complexe scenario's |

Handenvrij tellen in trilgoten zonder precieze eisen aan de singulatie. |

Nauwkeurige singulatie vereist; pillen moeten één voor één door de straal → trillingscontrole nodig. |

2.3 Omgaan met vormen: Voorbij bolvormige grenzen

Een op infrarood gebaseerde tablettenvulmachine is gebaseerd op een enkele infraroodstraal die een smal kanaal/kanaal doorkruist. Een pil wordt alleen geteld als deze de straal volledig onderbreekt. Dit werkt voor bolvormige, gelijkmatig gevormde pillen en capsules, maar faalt enorm bij:

- Onregelmatige pilvormen: Een gekantelde of asymmetrische pil kan een infraroodstraal slechts gedeeltelijk blokkeren, waardoor er te weinig wordt geteld.

- Beschadigde/gefragmenteerde pillen: Kleine fragmenten blokkeren de straal mogelijk helemaal niet, terwijl grote fragmenten als volledige pillen kunnen worden geregistreerd.

Ter vergelijking: in een visiongebaseerde tabletten tel- en vulmachine leggen hogesnelheidscamera's met intervallen van microseconden 2D/3D-beelden van elke pil vast. Vervolgens worden geavanceerde algoritmen gebruikt:

- Breng randen in kaart om niet-uniforme vormen te detecteren, zoals hartvormige vitaminepillen.

- Meet morfologische kenmerken zoals oppervlakte, omtrek, aspectratio om fragmenten van normale pillen te onderscheiden.

Voorbeeld: Een ovale tablet die tijdens het vallen schuin komt te staan, wordt nog steeds geteld omdat de capsule-telmachine de unieke omtrek herkent, niet de blokkade van de straal.

een vision-gebaseerde capsule-telmachine die een immense hoeveelheid softgels verwerkt

2.4 Transparantie hanteren: Onzichtbaar zien Items

In een op IR gebaseerde automatische capsule-telmachine kan infrarood licht, als het zonder noemenswaardige onderbreking door transparante medicijnen zoals plantaardige capsules en heldere softgels gaat, dit veroorzaken:

- Valse negatieven: Doorzichtige capsules blokkeren de infraroodstralen mogelijk niet, waardoor er te weinig wordt geteld.

- Inconsistentie met semi-transparante items: Variaties in de wanddikte van capsules of vloeibare vullingen leiden tot onstabiele bundelpenetratie, waardoor onbetrouwbare tellingen ontstaan.

Vergeleken met dit machinetype gebruikt een visiongebaseerde tabletteller CCD-camera's of CMOS-camera's en achtergrondverlichting + optische technologie met hoge resolutie. Dit helpt de teller om de belichtingshoeken en de belichting van de camera aan te passen, waardoor vage randen van heldere gels zichtbaar worden, aangezien transparante capsules het licht afbuigen, waardoor detecteerbare randen of schaduwpatronen ontstaan.

Voorbeeld: Een doorzichtige lege gelatinecapsule wordt geteld omdat de rand licht breekt, waardoor een herkenbare cirkelvormige omtrek ontstaat tegen een donkere achtergrond.

2.5 Surface Iinspectie van Elke pil: Niet-onderhandelbare cGMP-naleving

Een op vision gebaseerde capsule-teller maakt gebruik van hogeresolutiecamera's en geavanceerde beeldverwerkingssoftware om gedetailleerde oppervlakte-inspecties van elke tablet of capsule uit te voeren. Terwijl de pillen langs toevoerkanalen of een trilpaneel bewegen, legt de tabletteller meerdere high-definition beelden vast vanuit verschillende hoeken onder gecontroleerde belichting. Geavanceerde algoritmes analyseren deze beelden vervolgens pixel voor pixel en vergelijken het pillenoppervlak met vooraf gedefinieerde kwaliteitsparameters.

Met deze functionele hulp is de pillentelmachine in staat om uit te voeren:

- Defect Identificatie: Detecteert microscopische afwijkingen zoals tabletscheurtjes, oppervlaktekrasjes, deukjes, putjes in het oppervlak of verkleuringen van het materiaal die onzichtbaar zijn voor het blote oog of IR-sensoren.

- Besmettingsdetectie: Identificeert vreemde deeltjes, vlekken, olievlekken of poederresten op het oppervlak van de pil.

- Integriteitscontrole coating: Voor gecoate tabletten beoordeelt de tabletten-telmachine de uniformiteit, detecteert het scheurtjes in de coating, schilfers of vlekken.

- Markering Verificatie: Controleert de leesbaarheid, positionering en nauwkeurigheid van opdrukken of gravures zoals doseringscodes en farmaceutische logo's.

Deze realtime inspectie integreert kwaliteitscontrole direct in het telproces. Door automatisch defecte of vervuilde pillen te weigeren terwijl ze geteld worden, voorkomt een op vision gebaseerde telmachine voor pillencapsules dat gecompromitteerde medicijnen de verpakking bereiken. Het helpt het risico op het terughalen van producten te verlagen, verzekert de farmaceutische integriteit en garandeert strikte naleving van de cGMP-voorschriften.

2.6 Visie tellen van uitzonderlijk hoge snelheid

Vision-gebaseerde tablettellers bereiken aanzienlijk hogere snelheden, voornamelijk door niet-onderbrekende, parallelle verwerking. In tegenstelling tot IR-sensoren die pillen en capsules één voor één fysiek moeten breken, legt een high-speed camera meerdere keren per seconde een volledig beeldframe van het uitgiftegebied van medicijnen vast. Verfijnde beeldverwerkingsalgoritmen identificeren, lokaliseren en tellen vervolgens gelijktijdig alle zichtbare pillen binnen elk frame, ongeacht hun nabijheid, zolang ze niet perfect gestapeld zijn. Dit elimineert het kritieke knelpunt van IR-systemen: de verplichte fysieke scheiding van pillen om ervoor te zorgen dat slechts één pil tegelijk de infraroodstraal breekt.

Voordelen van een hogere verwerkingssnelheid:

- Enorme productieverhoging: Essentieel voor grootschalige farmaceutische productielijnen, waardoor de output 2 tot 3 keer hoger wordt.

- Minder samenvoegen van pillen nodig: Geen complexe afstelling van de apparatuur op trillingen of geforceerde scheidingsmechanismen die nodig zijn bij een automatische IR-tablettenteller om overlappende pillen te voorkomen die verkeerd tellen veroorzaken, waardoor het machineontwerp en de bediening vereenvoudigd worden.

Ruida Packing toont zijn vision-gebaseerde pillentellermachine op CPhI Expo 2025

2.7 Multi-Item Resolutie: Geen zorgen over het stapelen van pillen

Tellingen op basis van vision zijn uitstekend wanneer pillen elkaar overlappen of zich opstapelen terwijl ze door een kanaal bewegen. Om dit probleem aan te pakken, leggen hogesnelheidscamera's gedetailleerde beelden van de pillenstromen vast, waarna het beeldverwerkingssysteem de beelden analyseert om individuele pillen binnen een cluster te identificeren.

Met behulp van technieken als randdetectie, vormherkenning en AI-gestuurde segmentatie onderscheidt de vision-gebaseerde tablettellermachine grenzen, zelfs wanneer pillen en capsules elkaar gedeeltelijk verbergen. De pillenteller telt elke afzonderlijke gedetecteerde pilvorm. Een IR-straal registreert daarentegen slechts één onderbreking wanneer meerdere pillen tegelijkertijd de lichtstraal blokkeren - een klont telt als “één”, wat leidt tot een te lage telling.

Laatste lijnen: De ongeëvenaarde voordelen van vision-based pillentelling

Vision inspectie tabletten telmachines laten een duidelijke en meetbare superioriteit zien ten opzichte van conventionele IR-gebaseerde pillentellers, met name in de kritische farmaceutische productie. Terwijl IR tablettellers doorgaans een nauwkeurigheid van 99,0-99,5% bereiken, leveren geavanceerde vision telmachines een precisie van meer dan 99,99%. Deze extreme nauwkeurigheid, mogelijk gemaakt door hoge-snelheid, hoge-resolutie beeldvorming die minieme details van elke pil vastlegt, maakt vision technologie onmisbaar voor cGMP-conforme medische productie, merkgevoelige farmaceutica en hooggedoseerde precisietherapieën.

Naast tellen zorgen geïntegreerde vision inspectiemodules voor real-time kleuren en automatische afwijzing van niet-conforme of beschadigde items, waardoor een belangrijke laag kwaliteitscontrole wordt toegevoegd. Bovendien zorgen camerasystemen van industriële kwaliteit voor stabiliteit en betrouwbare werking, zelfs in productieomgevingen met veel stof. Voor fabrikanten die prioriteit geven aan foutloze uitvoer en integriteit van de toeleveringsketen, is visiongebaseerd tablettellen niet alleen een upgrade - het is de nieuwe standaard voor zekerheid in de moderne farmaceutische productie.