A tablettelmachine is the station on a bottling line where a small instability can turn into a batch-level headache.

When counting isn’t stable, problems show up fast—miscounts, chipped tablets that create fragments and dust that changes sensor behavior. The result is usually the same: rejects, rechecks, and stop-and-go running that hurts real throughput.

This Tablet Counting Machine Buying Guide keeps the decision process clear for first-time buyers, but detailed enough for engineers and QA teams. We’ll compare counter types, highlight the specs that actually drive stability, explain common miscount causes, and show how the counter should fit into a counting and bottling line.

Tablet counting machine basics for bottling lines

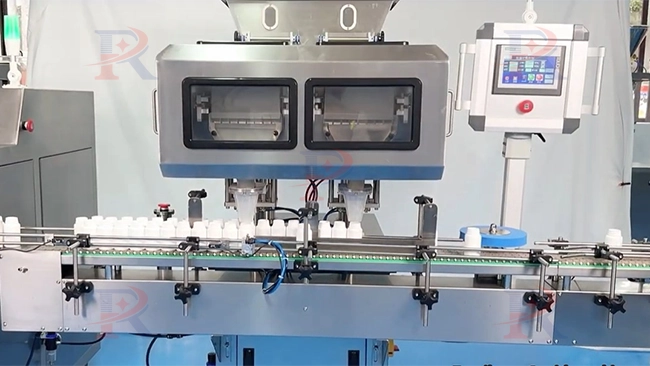

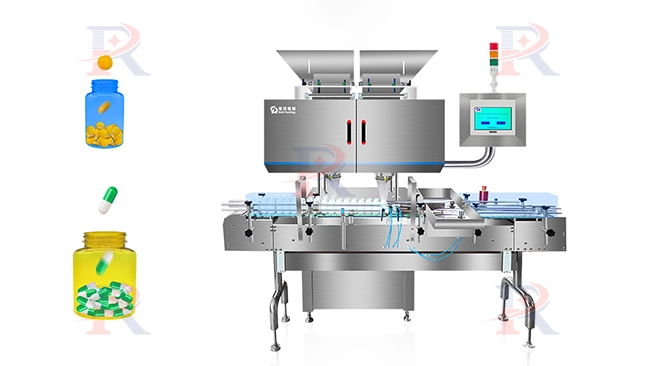

The tablet counting machine can not only operate independently but can also be integrated with bottle unscramblers, desiccant insertion machines, checkweighers, cotton insertion machines, capping machines, induction sealing machines, labeling machines, and sleeve labeling machines to form a complete tablet bottling line.

What the counter must do on a counting line

At line speed, the counter needs to do four things well: separate product consistently, count to the target, fill cleanly into the bottle without spillage, and remove wrong-count bottles reliably. That last part depends on reject handling (spacing + logic + confirmation)—otherwise the line stops too often or, worse, lets wrong-count bottles pass.

Definition of finished bottles per minute

The finished bottle output (bottles/min) of the tablet counter machine refers to the number of completed bottled units produced under defined conditions: a specific bottled unit (tablet/capsule/other), a specified bottle neck size, and a fixed number of filling units per bottle.

What makes counting harder in production

Counting becomes less predictable when the product doesn’t behave uniformly. Dusty tablets can leave residue that affects sensor stability; fragile edges can chip into fragments that confuse counting; static can cause sticking and random release; and shape variation matters more when you’re running multiple SKUs or switching between tablets and capsules on a tablet and capsule counting machine.

Before you request quotes

Have three answers ready: your product range (size/shape and whether it’s dusty or fragile), your typical count per bottle (min/max), and your target bottles/min plus changeover frequency. With that, the next step—choosing between photoelectric, vision, or slat counting—becomes much clearer.

Define your product, bottle, and line goal

Before you compare brands or models, lock down three inputs: what you’re counting, what you’re filling into, and what “good output” looks like on your floor.

Start with the product. Uniform, clean, hard tablets behave very differently from dusty chewables, fragile edges, or mixed SKUs. If you run capsules, transparency and length range also matter because they can change how sensors “see” product in the counting path.

Next is the bottle. A wide mouth gives you a forgiving fill window; a tight mouth increases spillage risk and makes bottle presentation more critical. If you plan to run multiple bottle sizes, note your smallest neck and your tallest bottle—both can affect bottle indexing and the drop height.

Finally, define line goal in bottles/min, not just counts/min. Your real throughput is limited by reject handling and downstream rhythm—desiccant insertion, cotton insertion, capping torque stability, and induction sealing.

Table 1 — Application → best-fit counter approach

| What you run most | What usually goes wrong | Best-fit approach to shortlist | Why it helps |

| Standard tablets, low dust, stable shapes | Occasional doubles/skips at speed | Foto-elektrisch (sensor) counter | Simple, fast, cost-effective when product is consistent |

| Mixed shapes/SKUs, higher variation, frequent audits | Miscounts hard to diagnose, reject confidence | Vision balie | Better visibility and verification when conditions vary |

| Fragile tablets, higher chip risk, gentle handling priority | Chips → fragments → false counts | Slat (or gentler handling design) + dust control | Mechanical separation can reduce bounce and breakage when tuned well |

| Dusty tablets/chewables | Sensor drift, residue buildup | Vision or enhanced dust management for sensor systems | More tolerant verification + easier detection of drift patterns |

| Tablets + capsules with frequent changeovers | Setup errors, longer downtime | Any type with strong changeover design | Quick change parts + recipes matter more than the counting method |

Photoelectric vs vision vs slat counters

A simple way to decide: if your product is consistent and clean, photoelectric often works; if you have more variation, dust, or stronger verification needs, put vision on the shortlist; if fragility and gentle handling dominate the conversation, slat-style separation may deserve a look.

Photoelectric counters count as product passes sensors across channels. They can be very stable with uniform tablets, but they’re more sensitive to dust, fragments, and “odd behavior” like sticking and random release.

Vision counters use cameras and algorithms to count and verify product flow. They often shine when you need better visibility into what’s happening in the channels, when product varies more, or when you want stronger confidence in reject decisions.

Slat counters mechanically separate product into lanes. They can be a good fit for certain products when set up correctly, especially where the mechanical flow reduces bounce and double-drops. The trade-off is typically more mechanical setup attention and change part management.

Table 2 — Counter type comparison (what matters in production)

| Item | Foto-elektrisch | Vision | Slat |

| Best for | Uniform tablets, stable flow | Variation, audits, verification | Gentle separation needs, certain fragile profiles |

| Dust sensitivity | Gemiddeld tot hoog | Lower (depends on design) | Medium (dust still affects guides) |

| Miscount risk drivers | Dust, fragments, bounce, static | Dirty optics/lighting extremes, heavy dust | Setup, wear, product damage patterns |

| Changeover | Usually fast if parts are simple | Fast if recipes + parts are organized | Can be slower if more mechanical adjustments |

| Speed ceiling | Often high on uniform product | High, with strong verification | Depends heavily on product + setup |

| Debugging issues | Can feel “invisible” | Usually easier (more visibility) | Mechanical diagnosis, setup-dependent |

Specs that drive stable counting

Once you’ve chosen a counter type, the next win is selecting specs that keep the machine stable day after day—not just on a short demo run.

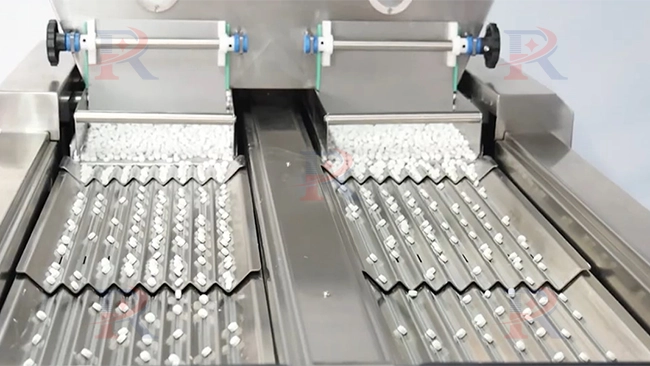

Feed stability is the foundation. A vibratory feeder should deliver a consistent, controlled flow into the counting channels without surging. More channels can increase potential speed, but it doesn’t automatically mean better performance if flow control is weak.

Reject handling is where many lines lose real throughput. If the reject system forces frequent stops—or rejects good bottles too easily—you’ll see stop-and-go running that kills bottles/min. Look for sane reject confirmation logic and smooth reject discharge that doesn’t disturb the good stream.

Changeover and cleaning are your silent cost. If you run many SKUs, quick-change parts, clear part labeling, and recipe settings reduce both downtime and operator mistakes.

Specs worth confirming in your quote/datasheet

- Material Dimensions

- Bottle Specifications

- Core Electrical Components

In this Tablet Counting Machine Buying Guide, treat the items above as non-negotiables—because they decide real bottles/min, not brochure speed.

Miscounting causes and fixes

The tablet counting machine often counts inaccurately due to three key issues. First, dust and powder can cover the photoelectric sensors, weakening or blocking the detection signal. Second, broken tablet or capsule fragments in the feeding path create false counting signals. Third, materials fail to separate completely during feeding, leading to overlapping particles that the sensors cannot identify individually.

To resolve these problems, clean the sensors regularly with compressed air or a soft brush to eliminate dust. Remove all broken fragments from the counting chute and feeding system. Adjust the feeding speed and vibrating mechanism to ensure full separation of each particle, enabling the sensors to detect and count accurately.

Also watch for “false speed wins.” If you push counts/min too hard, you can create more chips and dust, which then creates more miscounts and stops. In many plants, slightly reducing stress on the product increases the real bottles/min over a full shift.

FAT tests and accuracy verification

A showroom demo is not a buying decision. A practical FAT should prove stable flow at your target speed, repeatable accuracy over time, and correct handling of wrong-count bottles.

A practical FAT should include:

- Your worst-case product (dusty lot, fragile edges, or highest-variation SKU)

- A speed ramp (not just “one speed that looks good”)

- A long run to expose drift (dust buildup, static, heat, wear)

- Reject challenges (wrong count + spacing edge cases)

- A changeover check (time, parts, and operator error traps)

Use this Tablet Counting Machine Buying Guide as your FAT mindset: test for production reality, then ask for the records you’ll rely on after installation—FAT results format, change parts list for your SKU range, and a clear spares/wear-parts recommendation.

For accuracy verification, keep it realistic. Many teams combine a simple sampling plan with smart in-line checks where needed. If you add an in-line checkweigher or secondary verification, place it where it catches issues early without becoming a new bottleneck.

Line equipment after counting

In a tablet counting and bottling line (or capsule counting and filling line), the counter is the midpoint—not the finish line. After counting, you typically move through moisture protection and closure control before final coding and labeling.

A common sequence is: counting/filling → droogmiddelinbrenger → cotton inserter (if used) → cap feeding (cap elevator/sorter) → sluitmachine (torque control) → inductiesealmachine (foil seal) → coder (inkjet/laser) → Etiketteermachine. Optional stations like a checkweigher can sit after sealing/labeling depending on what you’re verifying and how you handle rejects.

Conclusie

A tablet counting machine can look similar across brochures, but the “right” choice is the one that stays stable with your real product, your real bottles, and your real line rhythm. Define the application first, shortlist the best-fit counter type, and focus on feed stability, bottle presentation, changeover design, and reject control—because those factors decide your actual bottles/min.

Use this Tablet Counting Machine Buying Guide to keep decisions grounded in production reality: prove performance with a practical FAT, verify accuracy in a way that fits your risk level, and make sure the counter integrates smoothly with downstream equipment like desiccant insertion, capping, and induction sealing.

FAQ

1) Photoelectric vs vision—what’s more reliable at speed?

For uniform, clean tablets, photoelectric can be very stable. If you see more variation, dust, or you want stronger verification confidence, vision tends to be easier to keep stable over time.

2) How do I handle dusty or fragile tablets?

Prioritize gentle handling design and dust management (extraction where it matters). Then tune feed stability before pushing speed.

3) Can one machine run both tablets and capsules with quick changeover?

Yes, but shortlist designs that make change parts and recipes simple. Changeover time and operator error risk often matter more than maximum speed.

4) What should a practical FAT include?

Worst-case product, speed ramp, long-run stability, and reject challenges that reflect real production issues—not just a short demo.

6) Where should a desiccant inserter sit on the line?

Typically after counting/filling and before capping, so moisture protection is in the bottle before closure and sealing steps.

7) Pharmacy pill counter vs industrial counter—what’s the difference?

Pharmacy counters focus on small-batch tray counts. Industrial counters are built for continuous bottle flow, stable feeding, reject control, and integration with downstream packaging stations.

Referenties

- FDA: Data Integrity and Compliance With Drug CGMP: Questions and Answers (Guidance for Industry). (Amerikaanse Food and Drug Administration)

- ISPE: Baseline Guide Vol 5: Commissioning & Qualification (2nd Edition) (overview page). (ISPE)