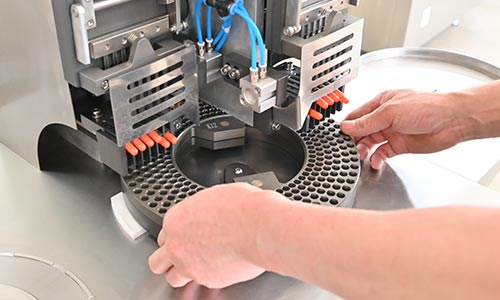

반자동 캡슐 충전기

반자동 캡슐 충진기 생산에는 작업자가 충진판을 공정의 여러 섹션 사이로 이동시키는 작업이 필요합니다. 이는 비용과 사용자 편의성 측면에서 더 효율적입니다.

사용 가능한 캡슐 크기:

|  |  |  |  |  |  |  | |

| 캡슐 크기 | #000 | #00 | #0 | #1 | #2 | #3 | #4 | #5 |

| 잠금 길이 | 26.14mm | 23.30mm | 21.7mm | 19.4mm | 18.0mm | 15.9mm | 14.3mm | 11.1mm |

| 캡슐 용량 | 1.37ml | 0.91ml | 0.68ml | 0.5ml | 0.37ml | 0.3ml | 0.21ml | 0.13ml |

(파우더 차이로 인해 충전량이 다를 수 있습니다)

반자동 캡슐 충전기는 어떻게 작동합니까?

반자동 캡슐 충전기의 전체 범위

| 모델 | CGN-208 | CGNT-209 |

| 산출 | 28,000개/시간 | 40,000개/시간 |

| 적용 가능한 캡슐 | 000#、00#、0#、1#、2#、3#、4#、5# | |

| 전원 공급 장치 | 2.12kw | 2.2kw |

| 힘 | 380/220V 50Hz(맞춤형) | |

| 순중량 | 400kg | 405kg |

| 포장 크기 | 1640*720*1700mm | 1640*720*1700mm |

제약회사를 위한 현명한 투자

사용하기 쉬움

비용 효율적

정확한

안전하게 작동 가능

오염 없음

우리는 포괄적인 서비스로 당신을 지원합니다

평생 보증

7일 이내 빠른 배송

24시간 온라인 서비스

자주 묻는 질문

- 캠을 정기적으로 윤활하여 좋은 상태로 유지하세요.

- 생산이 완료된 후에는 막힘과 녹을 방지하기 위해 충전 스테이션을 분해하고 청소하여 과도한 재료를 제거합니다.

- 진공 펌프에 윤활유를 정기적으로 추가하고 먼지를 청소하세요.

- 정기적으로 물탱크에 배럴 본체의 절반 정도 이상의 물을 채워주세요.

반자동 캡슐 충전기 작동 원리

반자동 캡슐 충전기는 빈 캡슐을 분리하고, 원하는 재료로 채우고, 닫습니다.

다음 단계가 포함됩니다.

- 캡슐 분리

- 주유소 설정

- 호페리얼 채우기

- 캡슐 정렬 및 방향

- 복용량 조절

- 캡슐 채우기

- 캡슐 폐쇄

- 채워진 캡슐 꺼내기

자동 vs. 반자동 캡슐 충전기

자동 캡슐 충전기

장점:

자동 기계는 고속 생산 기능을 제공하여 캡슐을 빠르고 효율적으로 채울 수 있으므로 대량 생산에 유용합니다.

최소한의 수동 개입만 필요하므로 많은 인력이 필요 없어지고 생산성이 높아집니다.

자동 기계는 정확한 투여량을 위해 설계되어 캡슐을 일관되고 정확하게 채울 수 있습니다.

캡슐 분류, 자동 캡슐 방향 조정, 온라인 검사 시스템 등의 추가 기능이 함께 제공되어 전반적인 운영 효율성을 높여줍니다.

단점:

자동 기계는 반자동 기계에 비해 초기 비용이 더 많이 들기 때문에 상당한 투자가 필요합니다.

자동 기계를 작동하고 유지관리하려면 복잡한 특성으로 인해 전문적인 교육과 기술적 전문성이 필요할 수 있습니다.

이러한 기계는 소량 생산이나 잦은 제품 변경에 적응하는 데 한계가 있을 수 있습니다.

자동 기계는 일반적으로 크기가 더 크고 제조 시설에서 더 많은 공간이 필요합니다.

반자동 캡슐 충전기

장점:

반자동 기계는 일반적으로 비용 효율성이 높아 예산이 제한된 소규모 제조업체나 스타트업에 적합한 옵션입니다.

이러한 시스템은 생산의 다양성 측면에서 더 큰 유연성을 제공하므로 소규모 또는 다양한 제품 라인에 쉽게 적용할 수 있습니다.

반자동 기계는 작동이 비교적 간단하고 기술적 전문 지식이 덜 필요하므로 교육과 유지관리가 쉽습니다.

이러한 기계는 일반적으로 크기가 작아 생산 공간에서 차지하는 공간이 적습니다.

단점:

반자동 기계는 캡슐 충전 과정에 작업자를 참여시키는 수동 처리가 더 많이 필요하므로 시간이 많이 걸리고 오류가 발생할 가능성이 있습니다.

수동 조작으로 인해 충전 속도가 제한되므로 자동 기계에 비해 생산 속도가 느립니다.

공정이 수작업으로 진행되기 때문에 충전 정확도나 캡슐 품질에 약간의 차이가 있을 수 있습니다.

일부 반자동 기계는 자동 기계에 비해 내구성이 떨어지거나 고장이 더 자주 발생할 수 있습니다.