錠剤選別スクリーニング機

錠剤選別スクリーニング機は、圧縮後の錠剤から余分な粉末を取り除き、錠剤が清潔で、さらなる加工や包装の準備が整っていることを確認するために使用されます。

錠剤の投入: 錠剤は通常、重力または振動フィーダーによって除塵室に運ばれます。

振動と移動:除塵装置は振動原理で動作します。モーターが振動を発生させ、錠剤を螺旋状または傾斜した穴あき経路に沿って移動させます。この振動により、錠剤の表面に付着した余分な粉末も除去されます。

粉塵分離: 穴のあいた通路またはスクリーンにより、粉末が落下し、錠剤から分離されます。

錠剤の研磨: 移動中に錠剤が互いに擦れたり、チャンバーの壁と擦れたりして、錠剤の表面が磨かれ、外観が向上します。

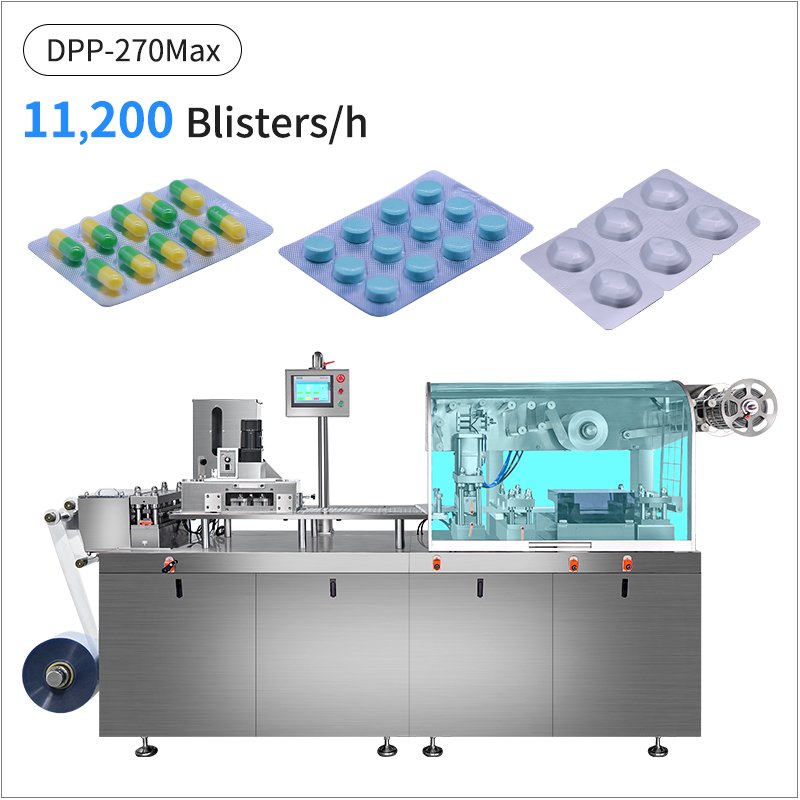

接続先 錠剤圧縮機、錠剤計数機、ブリスター包装機など。

仕様:

最大10万個/時

さまざまな形状やサイズの錠剤に適用可能

3日以内の迅速な配送