- Rumah

- Mesin Pengisi Kapsul

Mesin Pengisi Kapsul

Klasifikasi Mesin Pengisian Kapsul

| Model Mesin | NJP-400C | NJP-800C | NJP-1500D | NJP-2600C | NJP-3800D | NJP-5500C |

| Output Maksimum | 24000 pcs/jam | 48000 pcs/jam | 90000 pcs/jam | 150000 pcs/jam | 228000 pcs/jam | 330000 pcs/jam |

| Kompatibilitas Ukuran Kapsul | 000,00,0,1,2,3,4,5# | |||||

| Kekuatan | 3KW | 5 KW | 5,5 KW | 8KW | 10,5 KW | 11KW |

| Berat | 600kg | 900kg | 1200kg | 1500kg | 2200Kg | 3000Kg |

| Dimensi | Ukuran 1000×710×1900 mm | Ukuran 1100×910×2100 mm | Ukuran 1490×1260×2150mm | Ukuran 1650×1490×2150mm | Ukuran 1980×1850×2200mm | Ukuran 2400x2050x2300mm |

| Model | CGN-208 | CGNT-209 |

| Keluaran | 15000-30000 pcs/jam | 40000 pcs/jam |

| Kapsul yang Berlaku | 000#, 00#, 0#, 1#, 2#, 3#, 4#, 5# | |

| Catu daya | 2,12 kW | 2,2 kW |

| Kekuatan | 380/220V 50Hz (dapat disesuaikan) | |

| Berat bersih | 400kg | 405kg |

| Ukuran kemasan | Ukuran 1640*720*1700mm | Ukuran 1640*720*1700mm |

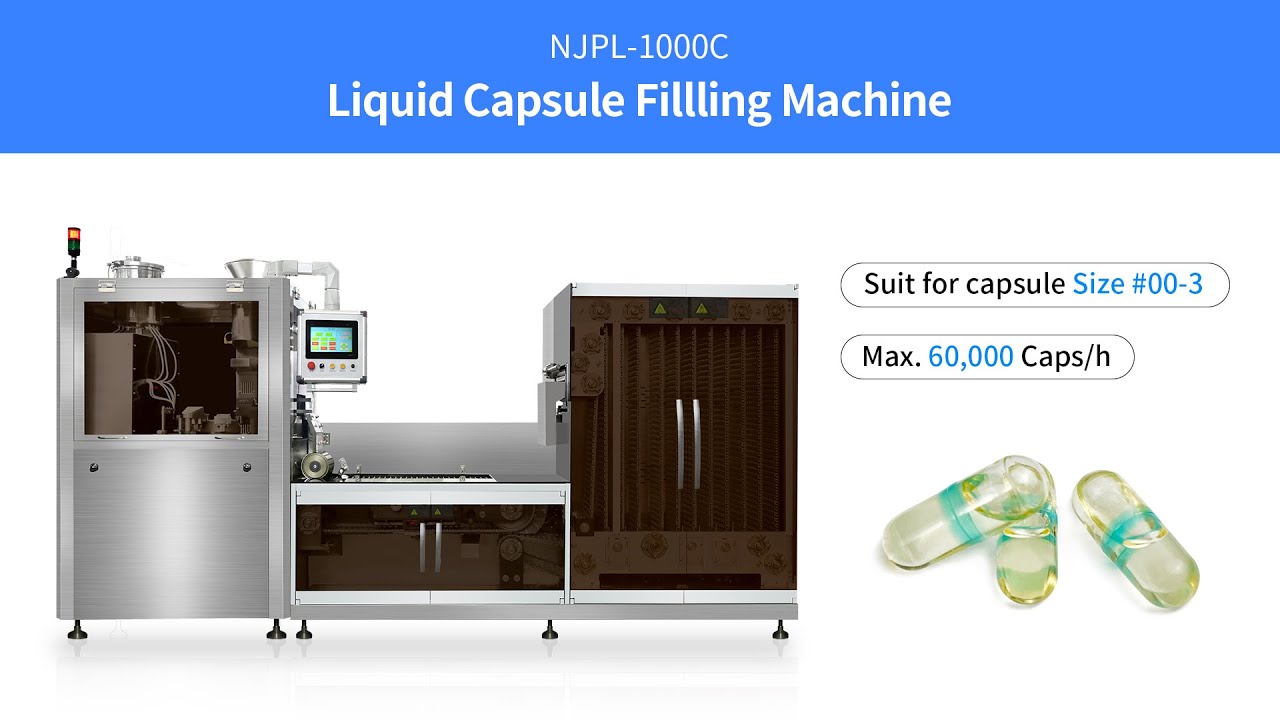

| Model | CGNL-300 | NJPL-100C | NJPL-300C | NJPL-600C |

| Keluaran | 15000-28000 pcs/jam | 100 pcs/menit | 300 pcs/menit | 600 pcs/menit |

| Kompatibilitas Ukuran Kapsul | 00#, 0#, 1#, 2#, 3# | |||

| Daya Total | 2,12 kW | 3,5 KW | 5 KW | 6KW |

| Kekuatan | 380/220V 50Hz (dapat disesuaikan) | |||

| Berat | 400 kg | 500 kg | 750 kg | 900 kg |

| Dimensi (P*L*T) | Ukuran 1300*800*1750mm | Ukuran 700*800*1700mm | Ukuran 860*960*1800mm | Ukuran 960*1000*1900mm |

Tidak yakin mesin mana yang terbaik untuk Anda? Tim kami dapat memberikan proposal berdasarkan kebutuhan dan anggaran Anda!

Mesin Pengisian Kapsul Otomatis

Manfaat

- Biaya tenaga kerja lebih rendah

- Output lebih tinggi daripada semi-otomatis dengan satu operator

- Otomatisasi terintegrasi untuk melengkapi kapsul

- Seluruh proses tanpa polusi

Aplikasi:

- ukuran: #000 hingga #5

- Bahan: pelet, bubuk, granul

Mesin Pengisian Kapsul Semi-Otomatis

- Mudah digunakan

- Biaya Mesin Lebih Rendah

- Output Lebih Tinggi dengan Lebih Banyak Operator

- ukuran: #000 hingga #5

- Bahan: pelet, bubuk, granul

Mesin Pengisi Kapsul Semi Otomatis

Semi automatic capsule filler machine can fill powder, granule, pellet and liquid into hard capsule, suitable for capsule size ...

Mesin Pengisian Kapsul Cair

Manfaat

- Teknologi terkini tanpa kebocoran

- Seluruh proses tanpa polusi

- Berbagai aplikasi cairan

Aplikasi:

- ukuran: #000 hingga #3

- Komposisi: cairan, minyak, cairan/kapsul mini, cairan/tablet mini, cairan/pelet

Mesin Pengisian Kapsul Cairan Otomatis NJPL-330C

NJPL-330C Automatic Liquid Capsule Filling Machine fills and seals oils, suspensions, pastes, and viscous solutions into hard capsules (sizes ...

Investasi Bijak untuk Industri Farmasi

Aplikasi Luas

Akurasi Tinggi

Hemat Biaya

Lokakarya Tanpa Kekacauan

Kami Mendukung Anda dengan Layanan Komprehensif

Garansi Seumur Hidup

Pengiriman Cepat dalam 7 Hari

Layanan Online 24/7

Pertanyaan yang Sering Diajukan

- Lumasi cam secara teratur untuk menjaganya dalam kondisi baik.

- Bongkar dan bersihkan stasiun pengisian untuk membersihkan material berlebih guna mencegah penyumbatan dan karat, setelah produksi selesai.

- Tambahkan oli pelumas ke pompa vakum secara teratur dan bersihkan debu.

- Isi air secukupnya lebih dari separuh badan tong ke dalam tangki air secara teratur.

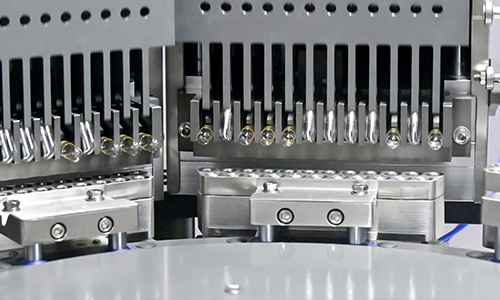

Prinsip Kerja Mesin Pengisi Kapsul

Langkah #1: Pemisahan Kapsul

Mesin tersebut memisahkan kapsul kosong menjadi dua bagian, biasanya menggunakan mekanisme mekanis atau berbasis vakum.

Langkah #2: Mengisi Bahan

Bahan pengisi yang diinginkan, seperti bubuk atau butiran, dimasukkan ke dalam hopper.

Langkah #3: Penutupan Kapsul

Mesin tersebut menyatukan kedua bagian kapsul, menyelaraskannya, dan menutupnya dengan aman menggunakan tekanan mekanis, penghisapan vakum, atau kombinasi keduanya.

Langkah #4: Ejeksi

Setelah kapsul ditutup, kapsul dilepaskan dari mesin, ke dalam wadah atau untuk pengemasan lebih lanjut.

Apa itu Mesin Pengisian Kapsul?

Mesin pengisian kapsul adalah alat yang digunakan dalam farmasi, nutrisi, Dan industri herbal untuk mengotomatiskan proses pengisian kapsul kosong dengan berbagai zat seperti bubuk, butiran, pelet, atau cairan.

Terdiri dari berbagai komponen, termasuk wadah kapsul, mekanisme untuk memisahkan dan mengarahkan kapsul, sistem pengisian, mekanisme penutupan, dan sistem ejeksi.

Mesin ini memfasilitasi pengisian kapsul secara efisien dan tepat, memastikan dosis dan keseragaman yang akuratMembantu meningkatkan kecepatan produksi, mengurangi biaya tenaga kerja, dan mempertahankan kontrol kualitas dalam proses pembuatan kapsul.

Jenis Utama Kapsul

Kapsul Cangkang Keras

- Kapsul bercangkang keras, yang juga dikenal sebagai kapsul dua bagian, terdiri dari bagian tutup dan badan terpisah yang disatukan untuk membungkus bahan pengisi. Tutup dan badan biasanya terbuat dari bahan gelatin atau bahan nabati.

- Kapsul keras menawarkan perlindungan produk yang sangat baik, stabilitas, dan fitur anti-rusak. Kapsul ini biasanya digunakan untuk bubuk kering, butiran, atau partikel padat kecil.

Kapsul Cangkang Lunak

- Kapsul bercangkang lunak terdiri dari cangkang tunggal gelatin atau cangkang vegetarian yang fleksibel. Kapsul ini sering disebut sebagai softgel atau kapsul softgel. Softgel biasanya diisi dengan bahan cair atau semipadat, seperti minyak, suspensi, atau pasta.

- Cangkang lunak memberikan keuntungan seperti peningkatan bioavailabilitas untuk formulasi berbasis lipid, peningkatan stabilitas untuk senyawa peka cahaya, dan kemudahan menelan.