- خانه

- دستگاه پر کردن کپسول

دستگاه پر کردن کپسول

Classification of Capsule filling Machine

| مدل ماشین | NJP-400C | NJP-800C | NJP-1500D | NJP-2600C | NJP-3800D | NJP-5500C |

| حداکثر خروجی | ۲۴۰۰۰ عدد در ساعت | ۴۸۰۰۰ عدد در ساعت | 90000 عدد در ساعت | 150000 pcs/h | ۲۲۸۰۰۰ عدد در ساعت | ۳۳۰۰۰۰ عدد در ساعت |

| سازگاری اندازه کپسولها | 000,00,0,1,2,3,4,5# | |||||

| قدرت | 3KW | 5KW | 5.5KW | 8KW | 10.5KW | 11KW |

| وزن | ۶۰۰ کیلوگرم | ۹۰۰ کیلوگرم | 1200Kg | ۱۵۰۰ کیلوگرم | 2200Kg | 3000Kg |

| ابعاد | 1000×710×1900mm | 1100 × 910 × 2100 میلیمتر | 1490×1260×2150mm | 1650×1490×2150mm | 1980×1850×2200mm | 2400x2050x2300mm |

| مدل | سیجیان-۲۰۸ | سیجیانتی-۲۰۹ |

| خروجی | 15000-30000pcs/h | 40000pcs/h |

| کپسول مناسب | ۰۰۰۱TP5T، ۰۰۱TP5T، ۰۱TP5T، ۱۱TP5T، ۲۱TP5T، ۳۱TP5T، ۴۱TP5T، ۵۱TP5T | |

| منبع تغذیه | ۲.۱۲ کیلووات | ۲.۲ کیلووات |

| قدرت | 380/220 ولت 50 هرتز (قابل تنظیم) | |

| وزن خالص | ۴۰۰ کیلوگرم | ۴۰۵ کیلوگرم |

| اندازه بسته بندی | 1640 * 720 * 1700 میلیمتر | 1640 * 720 * 1700 میلیمتر |

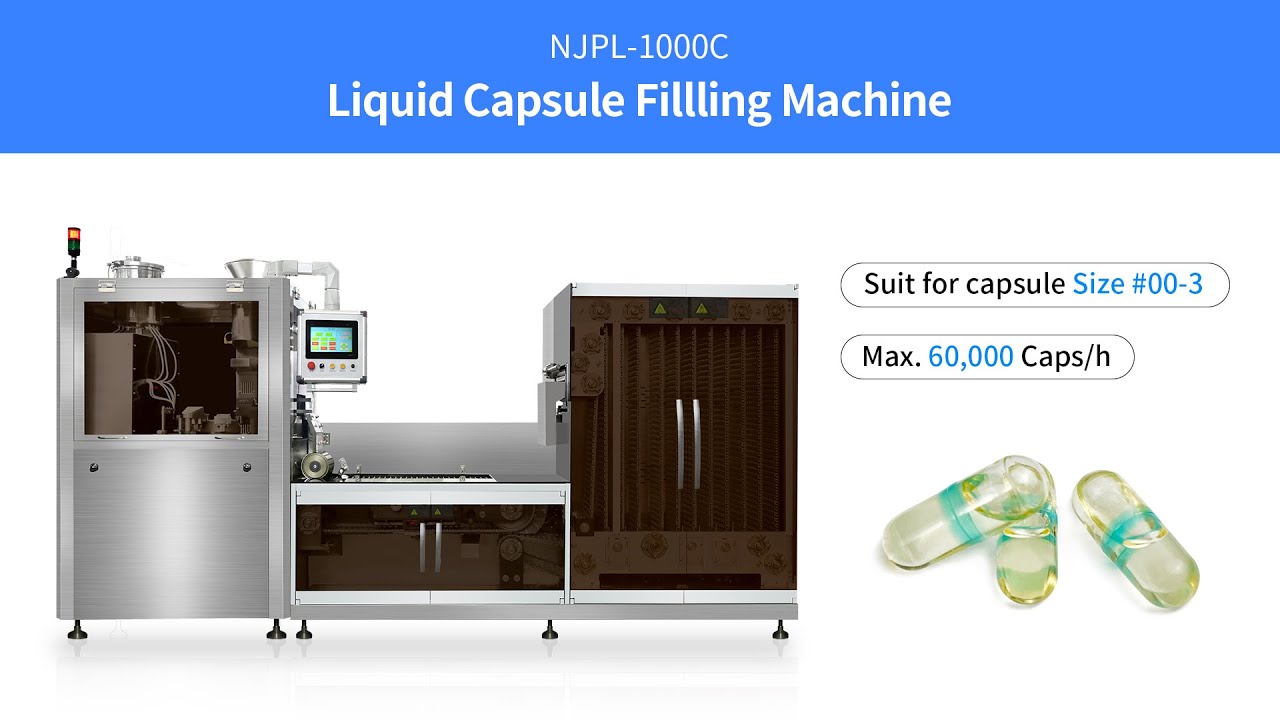

| مدل | CGNL-300 | NJPL-100C | NJPL-300C | NJPL-600C |

| خروجی | 15000-28000pcs/h | 100 pcs/min | 300 pcs/min | 600 pcs/min |

| سازگاری اندازه کپسولها | 00#、0#、1#、2#、3# | |||

| قدرت کل | ۲.۱۲ کیلووات | 3.5KW | 5KW | 6KW |

| قدرت | 380/220 ولت 50 هرتز (قابل تنظیم) | |||

| وزن | 400KG | 500KG | 750KG | 900KG |

| Dimension (L*W*H) | 1300*800*1750mm | 700*800*1700mm | 860*960*1800mm | 960*1000*1900mm |

مطمئن نیستید کدام دستگاه برای شما مناسبتر است؟ تیم ما میتواند بر اساس نیازها و بودجه شما پیشنهادی ارائه دهد!

دستگاه پر کردن کپسول اتوماتیک

مزایا

- Less labor costs

- Higher output than semi-automatic with one operator

- Integrated automation to complete capsule

- The whole process without pollution

Application:

- size:#000 to #5

- Ingredients: pellet, powder, granule

دستگاه پر کردن کپسول نیمه اتوماتیک

- آسان برای استفاده

- Lower Machine Costs

- Higher Output with More Operators

- size:#000 to #5

- Ingredients: pellet, powder, granule

دستگاه پرکننده کپسول نیمه اتوماتیک

Semi automatic capsule filler machine can fill powder, granule, pellet and liquid into hard capsule, suitable for capsule size ...

Liquid Capsule filling Machine

مزایا

- Latest technologies without leakage

- The whole process without pollution

- Various liquid application

Application:

- size: #000 to #3

- Ingredients: liquid, oil, liquid/mini capsule, liquid/mini tablet, liquid/pellet

دستگاه پرکن کپسول مایع خودکار NJPL-330C

NJPL-330C Automatic Liquid Capsule Filling Machine fills and seals oils, suspensions, pastes, and viscous solutions into hard capsules (sizes ...

یک سرمایهگذاری هوشمندانه برای داروسازی

Wide Application

دقت بالا

Cost Effective

No Messy Workshop

با خدمات جامع، هوای شما را داریم

ضمانت مادام العمر

تحویل سریع در ۷ روز

خدمات آنلاین 24 ساعته

سوالات متداول

- برای حفظ وضعیت مناسب، بادامک را مرتباً روغن کاری کنید.

- پس از اتمام تولید، پمپ بنزین را جدا و تمیز کنید تا مواد اضافی از آن خارج شود و از انسداد و زنگ زدگی جلوگیری شود.

- مرتباً روغن روان کننده را به پمپ خلاء اضافه کنید و گرد و غبار را تمیز کنید.

- به طور منظم، بیش از نیمی از بدنه بشکه را در مخزن آب به اندازه کافی آب بریزید.

اصل کار دستگاه پر کردن کپسول

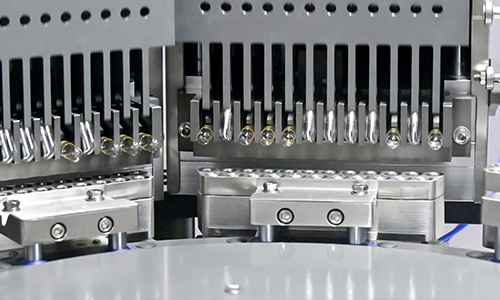

Step #1: Capsule Separation

The machine separates the empty capsules into individual halves, typically using mechanical or vacuum-based mechanisms.

Step #2: Filling Material

The desired fill material, such as powders or granules, is loaded into a hopper.

Step #3: Capsule Closing

The machine brings the capsule halves together, aligns them, and securely closes them using either mechanical pressure, vacuum suction, or a combination of both.

Step #4: Ejection

Once the capsules are closed, they are released from the machine, either into a container or for further packaging.

دستگاه پر کردن کپسول چیست؟

A capsule filling machine is a device used in the دارویی, nutraceutical، و herbal industries to automate the process of filling empty capsules with various substances such as powders, granules, pellets, or liquids.

It consists of different components, including a capsule hopper, a mechanism for separating and orienting the capsules, a filling system, a closing mechanism, and an ejection system.

The machine facilitates efficient and precise filling of capsules, ensuring accurate dosage and uniformity. It helps increase production speed, reduce labor costs, and maintain quality control in capsule manufacturing processes.

Main Types of Capsules

Hard-Shelled Capsules

- Hard-shelled capsules, also known as two-piece capsules, are composed of separate cap and body sections that fit together to enclose the fill material. The cap and body are typically made of gelatin or vegetarian materials.

- Hard capsules offer excellent product protection, stability, and tamper-evident features. They are commonly used for dry powders, granules, or small solid particles.

Soft-Shelled Capsules

- Soft-shelled capsules are composed of a single, flexible gelatin or vegetarian shell. They are often referred to as softgels or softgel capsules. Softgels are typically filled with liquid or semi-solid materials, such as oils, suspensions, or pastes.

- The soft shell provides advantages such as enhanced bioavailability for lipid-based formulations, improved stability for light-sensitive compounds, and ease of swallowing.