- Heim

- Kapselfüllmaschine

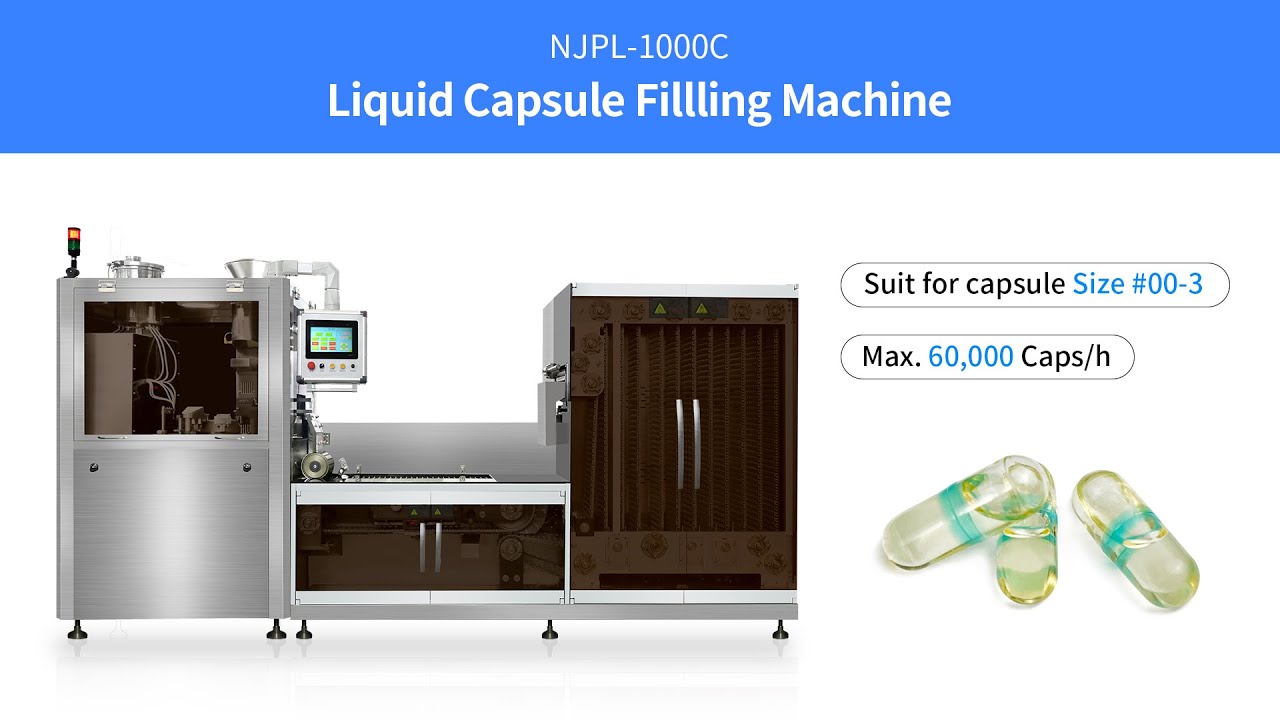

- Flüssigkapsel-Füllmaschine

Flüssigkapsel-Füllmaschine

Diese Maschine zum Herstellen von Flüssigkeitskapseln füllt und versiegelt vollautomatisch Flüssigkeiten und andere Materialien in leere Hartkapseln.

Es bietet vielen großen und kleinen Pharmaunternehmen und Herstellern von Gesundheitsprodukten eine hochaktive und unlösliche pharmazeutische Lösung zum Verpacken flüssiger Materialien.

Geeignete Kapselgrößen:

Die Maschine zum Abfüllen von Flüssigkeitskapseln ist in 8 Standardkapselgrößen erhältlich.

|  |  |  |  | |

| Kapselgröße | #00 | #0 | #1 | #2 | #3 |

| Gesperrte Länge | 23,30 mm | 21,7 mm | 19,4 mm | 18,0 mm | 15,9 mm |

| Kapselvolumen | 0,91 ml | 0,68 ml | 0,5 ml | 0,37 ml | 0,3 ml |

(Die Füllmenge kann aufgrund unterschiedlicher Pulverzusammensetzungen variieren.)

Wie es funktioniert

Abgesehen davon, dass die Maschine zum Abfüllen der flüssigen Zutat in eine Kapsel einfach nur die flüssige Zutat einspritzt, ist sie mit Arbeitsabschnitten und Technologien ausgestattet, die einen reibungslosen und effizienten Produktionsprozess gewährleisten.

Kapselrektifikation

Trennen von Kappen und Körpern

Füllflüssigkeit

Auswurf defekter Kapseln

Versiegelung

Trocknen

Das komplette Sortiment an Flüssigkeitskapsel-Füllmaschinen

Sie können aus einer großen Vielfalt an Maschinenmodellen mit unterschiedlichen Kapazitäten und Budgets wählen.

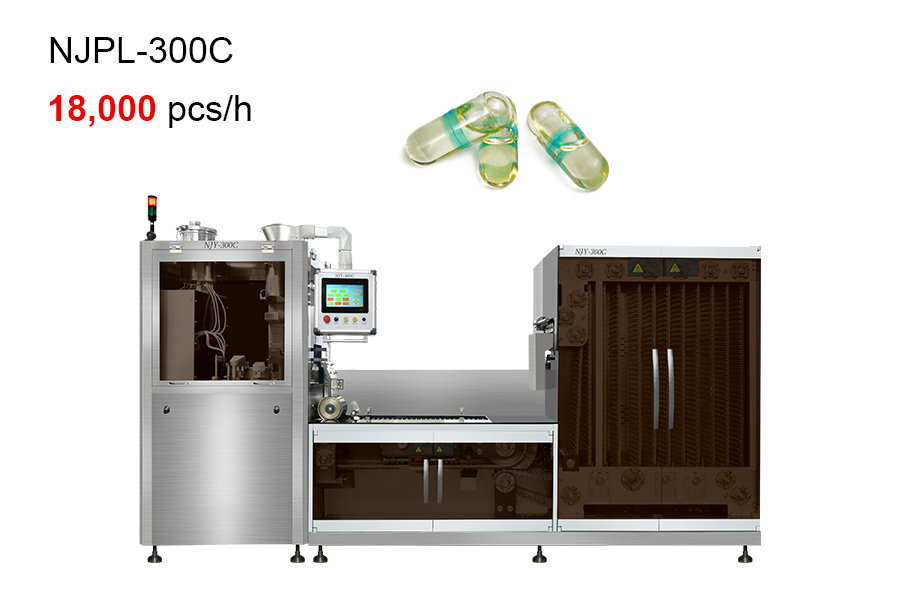

| Modell | CGNL-300 | NJPL-100C | NJPL-300C | NJPL-600C |

| Ausgabe | 15000-28000 Stück/h | 100 Stück/min | 300 Stück/min | 600 Stück/min |

| Kompatibilität der Kapselgrößen | 00#, 0#, 1#, 2#, 3# | |||

| Gesamtleistung | 2,12 kW | 3,5 kW | 5KW | 6KW |

| Leistung | 380/220 V 50 Hz (anpassbar) | |||

| Gewicht | 400 kg | 500 kg | 750 kg | 900 kg |

| Abmessungen (L*B*H) | 1300*800*1750 mm | 700*800*1700 mm | 860*960*1800 mm | 960*1000*1900 mm |

Sie sind sich nicht sicher, welche Maschine für Sie am besten geeignet ist? Unser Team erstellt Ihnen gerne ein Angebot, das auf Ihre Bedürfnisse und Ihr Budget zugeschnitten ist!

NJPL-330C Automatic Liquid Capsule Filling Machine

NJPL-330C Automatic Liquid Capsule Filling Machine fills and seals oils, suspensions, pastes, and viscous solutions into hard capsules (sizes ...

Eine kluge Investition für die Pharmaindustrie

Wir verpflichten uns, Maschinen höchster Qualität herzustellen, die den GMP-Standards entsprechen und gleichzeitig über effiziente und praktische Funktionen verfügen.

Hohe Genauigkeit

Mit dem Servomotor von Yaskawa aus Japan beträgt der Fehler bei der Flüssigkeitseinspritzung weniger als 2%. Das Problem der Ungleichmäßigkeit, das durch klebriges Material verursacht wird, wird durch die Keramikpumpe gut gelöst.

Kein Auslaufen

Ausgestattet mit der entsprechenden Versiegelungsflüssigkeit entsprechend dem vom Kunden verwendeten Kapseltyp ist die Versiegelung dicht und es tritt kein Leck aus.

Schadstofffrei

Das Drehdesign erhielt ein Patent für ein Gebrauchsmuster. Der SIL-Silikondichtring verhindert wirksam das Eindringen von Flüssigkeit in den inneren Drehteller und die Verschmutzung durch Staub.

Langlebiges Material

Alle Teile, die direkt mit den Zutaten in Berührung kommen, bestehen aus medizinischem Edelstahl 316L und das Ausgabegerät verfügt über sieben Leitungen aus Aero-Aluminium.

Wir unterstützen Sie mit umfassendem Service

Wir stehen Ihnen während des gesamten Prozesses zur Seite, von der Auswahl der geeigneten Maschine bis hin zu ihrer lebenslangen Pflege.

Lebenslange Garantie

Um Ihnen langfristig erstklassige Leistung zu garantieren, bieten wir Ihnen innerhalb von drei Jahren kostenlose Reparaturen und innerhalb eines Jahres kostenlose Ersatzteile. Danach versprechen wir Ihnen lebenslang kostenlose technische Beratung.

Schnelle Lieferung in 7 Tagen

95% unserer Standardmaschinen sind auf Lager. In diesem Fall kann der Versand innerhalb von 7 Tagen erfolgen. Bei stark kundenspezifischen Produkten beträgt die Lieferzeit nur 20 Tage.

24/7 Online-Service

Unsere kompetenten Kundenexperten und Ingenieure gehen gezielt auf Ihre Bedürfnisse ein und lösen alle Ihre Probleme innerhalb von 24 Stunden.

Die Hauptstruktur der Flüssigkapselmaschine

SPS-Steuerungssystem

Die Maschine verwendet das international bekannte Mensch-Maschine-Schnittstellen-SPS-Steuerungssystem und ermöglicht eine Echtzeitüberwachung des gesamten Betriebsvorgangs durch die SPS sowie automatische Alarme bei Kapsel- und Materialmangel.

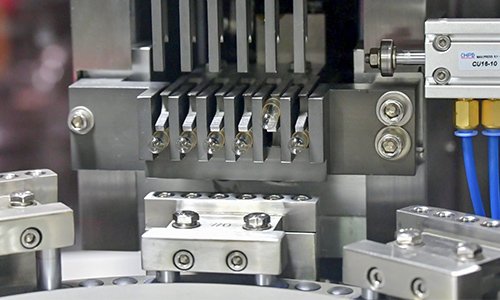

Leeres Kapselfüllsystem

Die speziell konfigurierte Kapselzuführungsmaschine verfügt über einen Vakuumpositionierungs- und Trennmechanismus, um sicherzustellen, dass die Kapselladerate über 99,5% liegt.

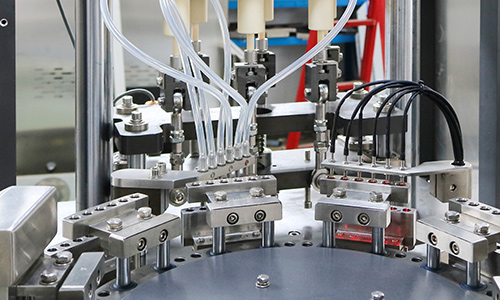

Flüssigkeitseinspritzsystem

Die Dosiergenauigkeit wird durch das Flüssigkeitszugabesystem mit Servomotor und hochpräziser Keramikpumpe gewährleistet, um sicherzustellen, dass die Differenz der Füllmenge des Kapselmaterials auf weniger als 2% kontrolliert wird.

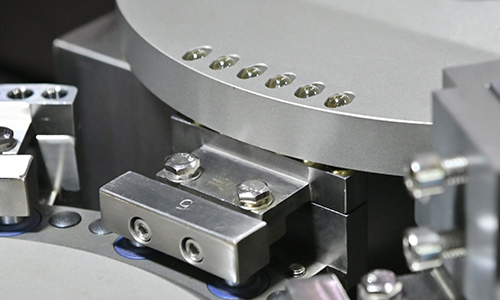

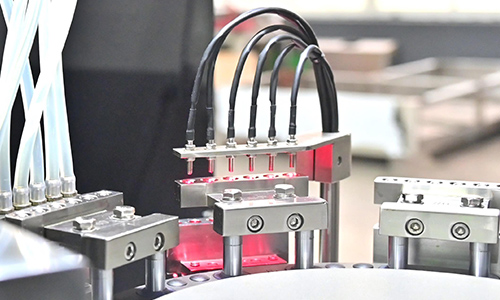

Dichtungssystem

Der Versiegelungsmechanismus des Flüssigkapselprodukts verwendet einen Servomotor zur Steuerung der Hebefunktion, der das Auf- und Abbewegen und die Feineinstellung des Gummirads ermöglicht und so die beste Wirkung der Flüssigkeitsversiegelungsschicht erzielt.

Wärmeerhaltungssystem

Die Versiegelungsstruktur ist im Flüssigkeitsversiegelungstank untergebracht und das Heiz- und Wärmeerhaltungssystem ist so ausgestattet, dass die Viskosität des Kapselklebers gewährleistet ist.

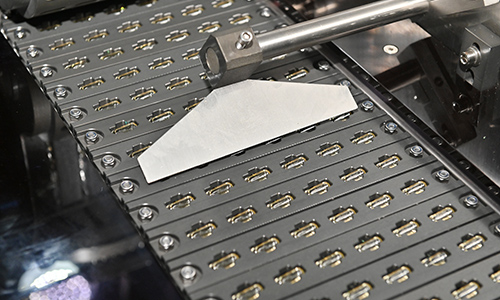

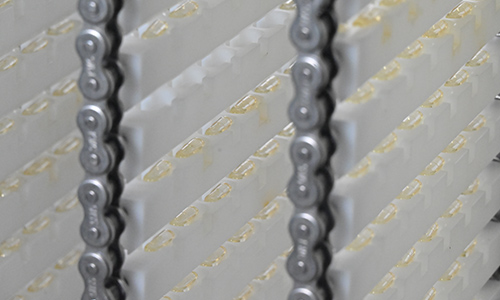

Trocknungssystem

Der Trocknungsmodus des fertigen flüssigen Hartkapselprodukts verwendet eine vertikale Aufhängung und eine frei rotierende Struktur, wodurch die Trocknungszeit der Kapsel sowie die Installations-, Demontage- und Reinigungszeit der Kapselfüllmaschine um 50% reduziert werden.

Häufig gestellte Fragen

Hier sind einige wichtige Details, die Sie berücksichtigen sollten, wie z. B. Kapselgröße und -typ, die verwendeten Inhaltsstoffe, die Produktionskapazität, die Maschinengröße und die Garantie. Da die Kosten für die Maschine ein hohes Budget darstellen, kann ein umfassender und langfristiger Kundendienst für ein langfristiges Geschäft von großem Nutzen sein.

CE: Europäische Konformität GMP: Gute Herstellungspraxis ISO: Internationale Organisation für Normung FDA: Food and Drug Administration

- Schmieren Sie die Nocke regelmäßig, um sie in gutem Zustand zu halten.

- Demontieren und reinigen Sie die Füllstation, um überschüssiges Material zu entfernen und so Verstopfungen und Rost nach Abschluss der Produktion zu verhindern.

- Geben Sie der Vakuumpumpe regelmäßig Schmieröl hinzu und reinigen Sie sie vom Staub.

- Füllen Sie regelmäßig ausreichend Wasser über die Hälfte des Fasskörpers in den Wassertank.

Wie füllt man Kapseln mit Flüssigkeit?

Erfahren Sie Schritt für Schritt, wie eine Maschine zum Abfüllen von Flüssigkeitskapseln funktioniert.

1. Kapselrektifikation

Die Flüssigkeitskapsel-Abfüllmaschine richtet die Kapseln aus und positioniert sie in der richtigen Ausrichtung für die Befüllung. Dadurch wird sichergestellt, dass die Kapseln für die Aufnahme der flüssigen Formulierung bereit sind.

2. Trennkapsel

Die Maschine trennt die Kapseln in Deckel- und Gehäuseteile. Dies ermöglicht eine individuelle Handhabung der Deckel und Gehäuse während des Füllvorgangs.

3. Füllflüssigkeit

Die Maschine füllt die flüssige Formulierung in die Kapseln. Die Füllparameter wie Volumen und Geschwindigkeit sind einstellbar, um eine präzise und gleichmäßige Befüllung zu gewährleisten.

4. Mängelausschluss

Die Maschine prüft die gefüllten Kapseln auf etwaige Mängel oder Auffälligkeiten. Ist eine Kapsel defekt, wird sie automatisch aus der Produktionslinie ausgeworfen.

5. Versiegelung

Die Maschine setzt die Kapselkappen auf die gefüllten Kapseln. Der Versiegelungsprozess sorgt für den sicheren Verschluss und die sichere Abdichtung der Kapseln.

6. Trocknen

Dieser Schritt entfernt überschüssige Feuchtigkeit oder Flüssigkeit aus den Kapseln.