- Trang chủ

- Chất lượng

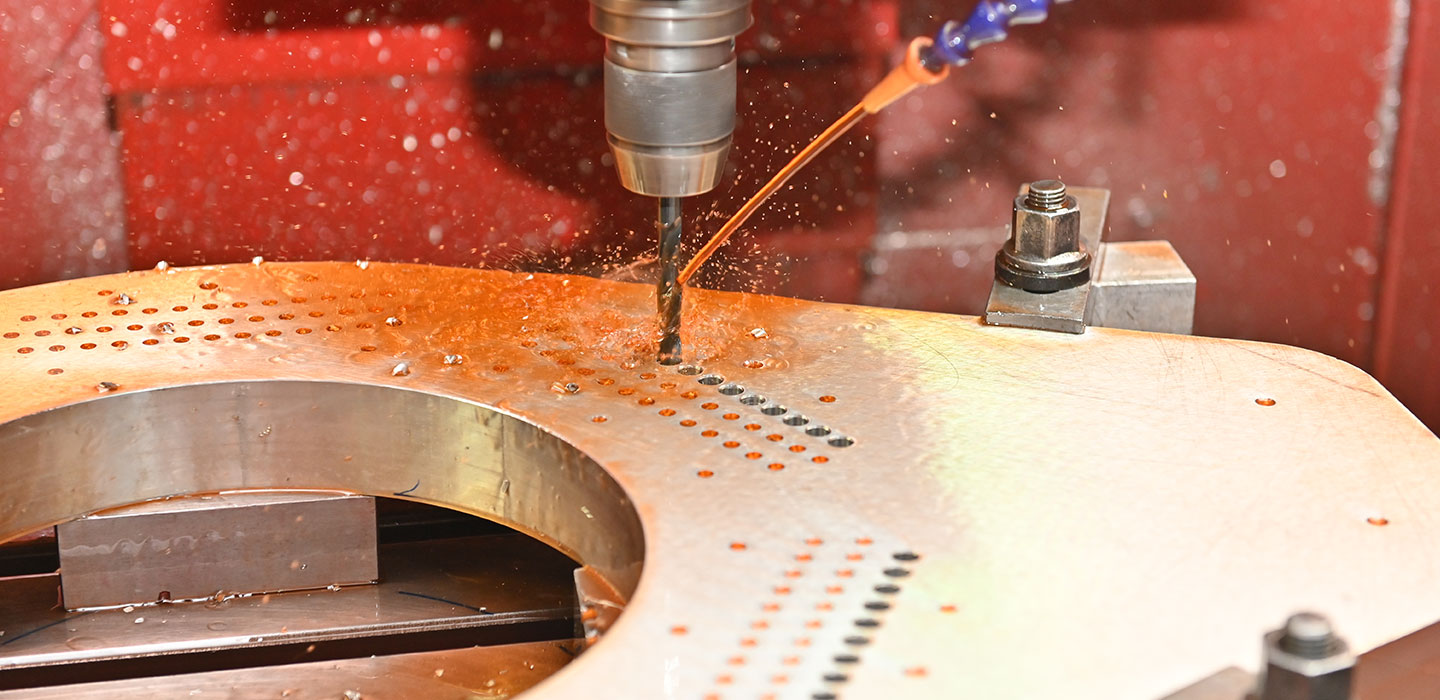

Production Process

CNC machining 1

CNC machining 2

Parts inspection

Lắp ráp máy đóng viên nang

Assembly of tablet press machine

Lắp ráp máy đếm viên thuốc

Tech inspection

Quality inspection

Delivery

Detailed Inspection Through Every Sections Of Our Process

Raw material Test

Test the carbon ratio of steel sheets and see whether it meet the medical and food grade.

Part / Mold Tolerance

Whether the precision meets the design requirements.

Pressure Test

Test the actual pressure level of the equipment.

Fatigue Test

Continuous 72 hours of power-on operation to test the machine durability.

Noise Test

Noise tester less than 75 dba meets the international requirements which reduces the harm to hearing.

Material Moisture Test

Test the available moisture range of the material to adjust the machine.

Tablet Condition Test

Test the hardness and dissolution of tablets to meet your formula.

Machine Balance Test

Test the balance of the equipment to prevent shaking while in operation.

Standardized Management Following 6S Guideline

Sorts: Clear out parts and tools that are not in use.

Set in order: Arrange all items used on a daily basis for easily access

Shine: Clean the workshop and make sure every section works properly.

Standardize: Develop a discpline for sort, set and shine

Sustain: Keep and follow the procedures

Safety: Identify abd eliminate all the potential hazards in workshop