In the world of product packaging, especially for pharmaceuticals, blister packaging has long been a popular choice. Its transparent plastic shell offers excellent product visibility, allows consumers to inspect the item directly, and provides a degree of tamper evidence. However, despite its widespread use, blister packaging comes with a set of significant limitations that can impact product integrity, user experience, and brand perception. So, what happens after the product is sealed in its blister? Often, the next crucial step is employing carded packaging. But why is this secondary packaging necessary?

1. The Unseen Flaws of Blister Packaging

Before we dive into the solution, it’s essential to understand the problems we’re aiming to solve. Blister packaging, while useful, has several inherent drawbacks:

1.1. Susceptibility to Damage

The plastic blisters, often made from PVC or PET, can be relatively fragile. They are prone to being crushed, cracked, or punctured during shipping, handling, or even on store shelves. A damaged blister compromises the product’s sterility and safety, leading to potential returns and customer dissatisfaction.

1.2. Poor Portability and Storage

Individual blisters are slippery, awkwardly shaped, and difficult to carry conveniently. Think of pills; loose blisters can easily get lost in handbag. They lack a unified structure, making them inconvenient for consumers to organize and transport.

1.3. Limited Branding Real Estate

The surface area of a blister is primarily dedicated to the product visibility. While the backing material (usually a foil) can hold some information, the space for impactful branding, detailed instructions, and marketing messages is severely restricted. This makes it challenging for brands to establish a strong shelf presence or communicate key value propositions effectively.

1.4. Unprofessional Presentation

A standalone blister can sometimes appear cheap or industrial. For many consumer products, projecting an image of quality and reliability is paramount. A flimsy blister alone often fails to achieve this.

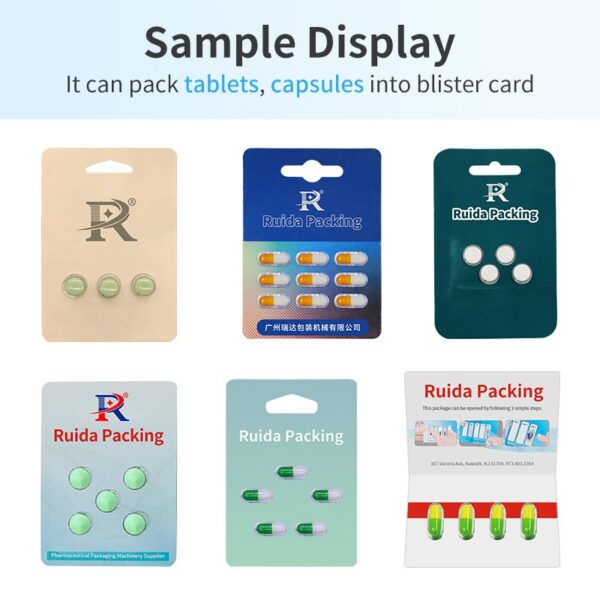

The most effective method to overcome these limitations is to pair the blister with a paperboard card. This process, known as blister card packing, creates a robust, professional, and consumer-friendly unit. The primary machine that automates this process is called a blister card packing machine.

2. What is a Blister Card Packing Machine?

A blister card packinging machine is an automated or semi-automated packaging system designed specifically to seal a formed blister pack into a printed paperboard card. It streamlines the process, ensuring speed, consistency, and a high-quality seal. These machines are vital in industries requiring efficiency and presentation, such as pharmaceuticals, hardware, toys, and cosmetics.

3. The Workflow of a Blister Card Packing Machine

The operation of a blister card packing machine is a precise and sequential process. While specific models may vary, the fundamental workflow typically involves the following stages:

3.1. Card Feeding (Picking the Card)

The process begins with a stack of pre-cut, pre-printed paperboard cards loaded into a feeder. The machine automatically picks a single card and positions it precisely onto the machine’s sealing platen. These cards are the canvas for branding, containing product information, logos, barcodes, and usage instructions.

3.2. Blister Placement (Picking the Blister)

Simultaneously, the formed blister packs, containing the products, are fed into the machine. This can be done via an automated feeding system. The machine picks up each blister and aligns it perfectly over the pre-positioned card. The product within the blister is clearly visible through the plastic cavity.

3.3. Backing Material Application (Picking the Backing Card)

In some configurations, especially for skin packaging, a thin film of plastic is heated and draped over the blister and card. However, in a more common method for sealed blisters, the backing is already part of the card pack. The blister card packing machine’s role here is to secure the blister to the card. The critical step is the application of heat sealing.

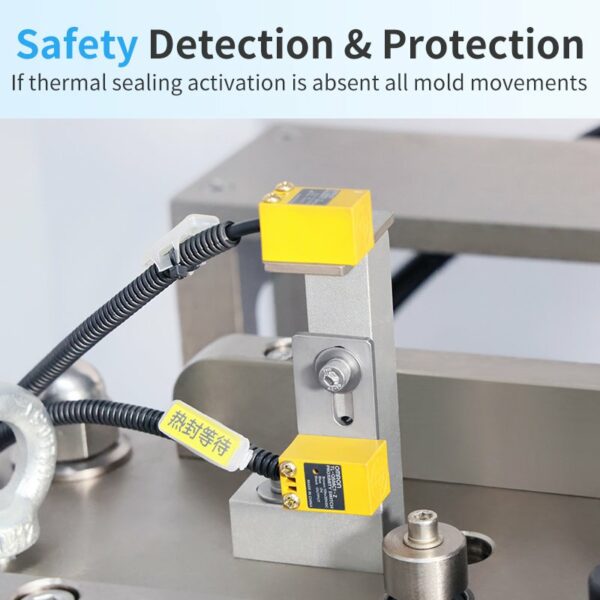

3.4. Heat Sealing

This is the core of the process. The machine’s sealing platen, which holds the card and blister assembly, moves under a heated head.

The pressure, temperature, and dwell time are carefully controlled to ensure a perfect, tamper-evident seal without damaging the product or the card.

3.5. Output

After sealing, the package is ejected from the sealing station. The finished product a sturdy carded blister pack is then discharged, ready for collection and final packaging into cartons.

4. The Advantages of Blister Card Packaging

By integrating the blister with a card using a blister card packing machine, manufacturers solve the initial problems and gain significant advantages:

4.1. Dramatically Enhanced Durability

The rigid paperboard card provides a sturdy backing that prevents the blister from being bent or crushed. The product is now protected from impact and compression during transit and storage, drastically reducing damage rates and associated costs.

Superior Portability and Handling: The flat, card-backed package is easy for consumers to handle, store, and carry. It can be neatly slotted into a pocket or a bag without fear of damage. Many cards are designed with a hang tab, allowing for attractive and space-efficient pegboard display in retail environments.

4.2. Amplified Branding and Communication

The paperboard card offers a large, printable surface area. This is a marketer’s dream. It allows for high-quality graphic design, vibrant brand colors, compelling marketing copy, and clear, legible instructions. This enhanced presentation builds brand value, aids consumer decision-making at the point of sale, and differentiates the product from competitors.

4.3. Increased Perceived Value

A carded blister pack feels more substantial and premium than a loose blister. This elevated presentation justifies a higher price point and fosters a sense of quality and trust in the consumer’s mind.

4.4. Improved Tamper Evidence and Security

The secure seal created by the carding machine makes tampering immediately visible, providing an additional layer of safety and assurance for the end-user.

In conclusion, while blister packaging offers functional benefits, its weaknesses are too significant to ignore for brands serious about quality, customer satisfaction, and market presence. The simple yet brilliant solution of pairing it with a paperboard card, efficiently executed by a blister card packing machine, transforms a basic package into a robust, portable, and powerful branding tool. It’s a strategic investment that protects the product, enhances the user experience, and ultimately, strengthens the brand. In today’s competitive market, blister card packaging isn’t just an option; it’s a smart and essential step for any product that deserves to be presented and protected in the best way possible.