- Ev

- Kapsül Dolum Makinesi

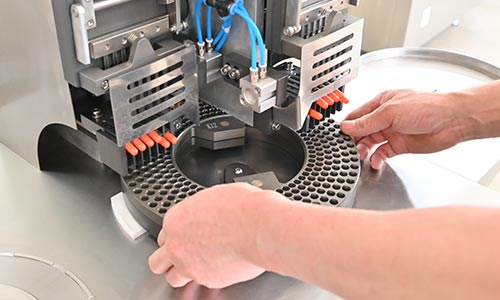

- Yarı Otomatik Kapsül Dolum Makinesi

Yarı Otomatik Kapsül Dolum Makinesi

Yarı otomatik kapsül dolum makinesinin üretimi, dolum plakalarını işlemdeki farklı bölümler arasında hareket ettirerek bir operatörün yardımına ihtiyaç duyar. Daha uygun maliyetli ve kullanıcı dostudur.

Yetenekli Kapsül boyutları:

|  |  |  |  |  |  |  | |

| Kapsül Boyutu | #000 | #00 | #0 | #1 | #2 | #3 | #4 | #5 |

| Kilitli Uzunluk | 26,14 mm | 23.30mm | 21,7 mm | 19,4 mm | 18.0mm | 15.9mm | 14,3 mm | 11.1mm |

| Kapsül Hacmi | 1.37 ml | 0.91 ml | 0,68 ml | 0,5 ml | 0.37 ml | 0,3 ml | 0.21ml | 0.13ml |

(Dolum miktarı toz farklılığından dolayı değişebilir)

Yarı Otomatik Kapsül Dolum Makinesi Nasıl Çalışır?

The Complete Range of Semi-automatic Capsule Filling Machines

Yarı Otomatik Kapsül Dolum Makinesi

Yarı otomatik kapsül doldurma makinesi, toz, granül, pelet ve sıvıyı sert kapsüle doldurabilir, kapsül boyutu için uygundur ...

| Örnek | CGN-208 | CGNT-209 |

| Çıktı | 28,000pcs/h | 40,000pcs/h |

| Uygulanabilir Kapsül | 000#、00#、0#、1#、2#、3#、4#、5# | |

| Güç kaynağı | 2.12kw | 2.2kw |

| Güç | 380/220V 50Hz (özelleştirilebilir) | |

| Net ağırlık | 400kg | 405 kilo |

| Ambalaj boyutu | 1640*720*1700mm | 1640*720*1700mm |

İlaç Sektörü İçin Akıllıca Bir Yatırım

Kolay Kullanım

Cost-Friendly

Accurate

Safe to Operate

No Pollution

Kapsamlı Hizmetle Arkanızdayız

Ömür boyu garanti

7 Günde Hızlı Teslimat

7/24 Çevrimiçi Hizmet

Sıkça Sorulan Sorular

- İyi durumda tutmak için kamı düzenli olarak yağlayın.

- Üretim bittikten sonra tıkanma ve paslanmayı önlemek için fazla malzemeyi temizlemek için dolum istasyonunu sökün ve temizleyin.

- Vakum pompasına düzenli olarak yağlama yağı ekleyin ve tozu temizleyin.

- Su tankına düzenli olarak varil gövdesinin yarısını geçecek kadar su doldurun.

Semi-automatic Capsule Filling Machine Working Principle

A semi-automatic capsule filling machine separates empty capsules, fills them with the desired material, and closes them.

It involves following steps:

- Capsule separation

- Filling station setup

- Filling the hopperial

- Capsules alignment and orientation

- Dosage adjustment

- Filling the capsules

- Kapsül Kapatma

- Ejecting the filled capsules

Automatic vs. Semi-automatic Capsule Filling Machine

Otomatik Kapsül Dolum Makinesi

Pros:

Automatic machines offer high-speed production capabilities, filling capsules quickly and efficiently, which is beneficial for large-scale manufacturing.

They require minimal manual intervention, reducing the need for extensive human labor and increasing productivity.

Automatic machines are designed for precise dosing, ensuring consistent and accurate filling of capsules.

They often come with additional features such as capsule sorting, automatic capsule orientation, and online inspection systems, enhancing overall operational efficiency.

Cons:

Automatic machines tend to have a higher upfront cost compared to semi-automatic machines, making them a significant investment.

Operating and maintaining automatic machines may require specialized training and technical expertise due to their complex nature.

These machines may have limitations when it comes to accommodating small-batch production or frequent product changes.

Automatic machines are generally larger and require more space in the manufacturing facility.

Yarı Otomatik Kapsül Dolum Makinesi

Pros:

Semi-automatic machines are generally more cost-effective, making them a viable option for smaller manufacturers or startups with limited budgets.

They offer more flexibility in terms of production versatility, allowing easier adaptation for small-scale or diverse product lines.

Semi-automatic machines are relatively simpler to operate and require less technical expertise, enabling easier training and maintenance.

These machines are typically smaller, occupying less space in the production area.

Cons:

Semi-automatic machines require more manual handling, involving operators in the capsule filling process, which can be time-consuming and potentially introduce errors.

The filling speed is limited by manual handling, resulting in slower production rates compared to automatic machines.

There may be slight variations in filling accuracy or capsule quality due to the manual nature of the process.

Some semi-automatic machines may be less durable or prone to more frequent breakdowns compared to their automatic counterparts.