Among the most persistent and frustrating issues that can halt a production line is the problem of sticking tamping pin on an automatic capsule filling machine. This phenomenon is that the powder adheres to the metal tamping pin of the filling station, leads to incomplete fills, dosage inaccuracies, machine jams, and ultimately, contaminated batches.

Understanding and preventing sticking is crucial for any professional looking to tamping pin a highly reliable capsule filling machine. This article will delve into the root causes of this common problem and explain how to provide a better solution.

1. Why Does Powder Stick to the Tamping Pin?

Sticking tamping pin are rarely caused by a single factor. Instead, it’s often a perfect storm of raw material properties, machine conditions, and environmental factors.

1.1. Powder Characteristics

The formulation of your powder is the primary culprit. Key characteristics that contribute to sticking include:

Moisture Content: Hygroscopic powders (those that attract and hold moisture from the environment) can become sticky, creating a strong bond with the metal tamping pin surfaces.

Particle Size and Shape: Fine, cohesive powders with irregular shapes have a greater surface area and tend to interlock, making them more prone to adhesion than free-flowing, spherical particles.

Composition: Formulations with high concentrations of fats, oils, or certain sticky APIs (Active Pharmaceutical Ingredients) can naturally act as adhesives.

1.2. Tamping Pin Head Material and Finish

The tamping pin themselves play a critical role. A rough or poorly finished tamping pin surface provides more microscopic “anchors” for the powder to grip onto. Furthermore, the type of metal and its surface treatment directly impact its non-stick properties.

1.3. Workshop Temperature and Humidity

Temperature and humidity control is the most overlooked factor. High humidity can moisture the powder, while high ambient temperature can soften certain excipients or APIs, increasing their tackiness. A fluctuation of just a few degrees or percentage points in relative humidity can be the difference between a smooth run and constant stoppages.

2. An Integrated Approach to Tamping Pin Sticking Prevention

The Ruidapacking NJP-1500D automatic capsule filling machine is engineered not just as a high-speed capsule filler, but as a comprehensive solution to manufacturing headaches. Here’s how it tackles each cause of sticking head-on.

2.1. Precision Engineering for Diverse Powder Handling

The NJP-1500D is designed with versatility in mind. Its metering system is carefully calibrated to handle a wide range of cohesive powders.

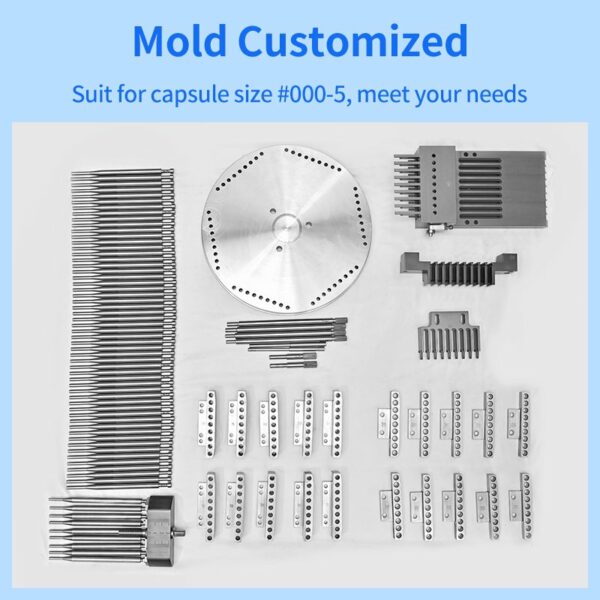

Optimized Dosing Discs: The machine features precisely machined dosing discs and tamping pins that ensure consistent powder compression without over-packing, which can exacerbate sticking.

Anti-Sticking Mechanisms: Critical contact points are designed to minimize flat surfaces where powder can accumulate, promoting a clean release.

2.2. Superior Tamping Pins Head Quality and Optional Coatings

We believe the solution starts with the tooling. The standard tamping pins supplied with the NJP-1500D are made from high-grade, durable stainless steel with an exceptionally smooth, polished finish to minimize adhesion.

Optional Coatings: For exceptionally challenging formulations, we offer tamping pins with specialized coatings such as Chromium Nitride (CrN) or Teflon-impregnated surfaces. These coatings create an ultra-hard, low-friction barrier that significantly reduces the surface energy, preventing even the stickiest powders from adhering.

2.3 The Filling Station Utilizes a Fully Enclosed Design

While we cannot control your entire facility environment, this design minimizes the powder’s exposure time in the feed hopper and batching system, reducing its exposure to ambient humidity before packaging. This prevents secondary contamination of the raw materials and complies with cGMP standards.

3. Best Practices for Operators Using the NJP-1500D

To maximize the performance of NJP-1500D capsule filling machine, we recommend these operational best practices:

Powder Pre-conditioning: Ensure your powder is properly dried and sieved before loading. If necessary, use a dehumidifier or air conditionern the production area to maintain a stable environment (ideally 20-25°C and 40-50% RH).

Consistent Tooling Maintenance: Establish a regular cleaning and inspection schedule for the tamping pins. Even the coatings can wear over time. Clean punches with appropriate solvents to remove any film buildup.

Conclusion

Sticking tamping pins are a solvable problem. By choosing the NJP-1500D automatic capsule filling machine from Ruidapacking, you are not just purchasing a capsule filling machine; you are investing in a system designed for reliability and efficiency. Its thoughtful engineering addresses the core issues of powder sticking, minimizing downtime, reducing waste, and ensuring the consistent quality of your capsule products.